Hard concrete floors has the chance to intensify sounds, though this weakness may be rectified without difficulty by the addition of some judiciously placed rugs, mats or runners. In simple terms, polished floors generate use of concrete polishing that is a mechanically ground material that is therefore polished to reach a certain appearance.

Images about Concrete Floor Epoxy Filler

Concrete Floor Epoxy Filler

The expression which relates to a selection of decorative concrete flooring options that typically end up leaving a concrete surface area preferably exposed as the previous final as well as final floor finishing. For a comprehensive cleaning, wash the floor which has a concrete cleaner and then follow with a good rinsing. Little bumps and ridges are made on textured concrete floor surfaces for a better traction while walking.

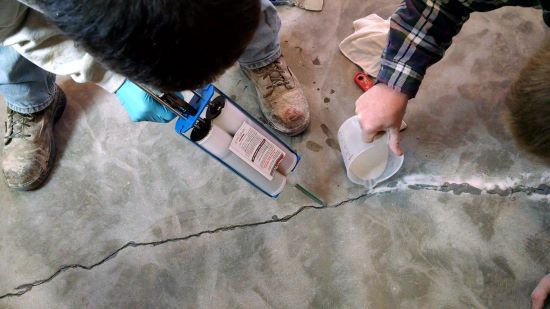

DIY Epoxy Concrete Crack Repair – What I use – How I Repair Concrete

A number of profits of polished concrete flooring are the long life of its, as well as the virtually limitless design alternatives available. Concrete flooring is ideal for warm climates since it stays cool even in probably the hottest weather conditions. If you're setting up the floor of your home or office to be concreted, you'll find a few things you need to consider.

Epoxy Concrete Patch Repair Damaged Plant Floors u0026 Expansion Joints

FAST SET EPOXY PATCH KIT, 1 u0026 2 GAL

Concrete Pore Filler / Epoxy Repair Mortar – CLEAN TECH ERM, CLEAN

Epoxy Damaged Concrete Repair Concrete Crack Repair Epoxy Jemkon

When to call a professional to repair cracked concrete

HyperFLEX Epoxy Flexible Membrane Concrete Wood Low Temp 40°F 100% Solids

Epoxy Floor Coatings: What about the Cracks? (Part 1)

HyperREZ UV Low Temp 40°F High Build Epoxy Concrete Floor Coating 100% Solids

Garage Epoxy Flooring Concrete Repair Resurfacing

How to repair epoxy coating failure? Duraamen

Concrete Floor Crack and Patch Repair Floor Patcher Paste u2013

Garage Floor Epoxy Everything you need to know BuyersAsk

Related Posts:

- High Gloss Concrete Floor Sealer

- Concrete Floor Finishes

- Tinted Concrete Floors

- Concrete Floor Refinishing DIY

- Concrete Floor For Garage

- Concrete Floor Cleaning Tips

- DIY Concrete Floor Paint

- Gray Concrete Floor Paint

- Concrete Floor Cleaning Solution

- Redo Concrete Floors

Introduction

Concrete floor epoxy filler is a specialized product used to fill in cracks and other imperfections in concrete surfaces. It is specially formulated to be strong, durable and easy to apply. Epoxy filler can be used on both interior and exterior concrete surfaces, making it a great solution for homeowners and businesses. The epoxy filler provides a smooth, even finish that will last for years. It also provides protection from water, oil and other contaminants that can damage the concrete surface.

Advantages of Concrete Floor Epoxy Filler

Concrete floor epoxy filler offers many advantages over traditional fillers such as concrete patching compounds. First, it is easy to apply and can be used on both interior and exterior surfaces. Second, it provides a strong bond that won’t crack or chip over time. Third, it is resistant to water, oil and other contaminants that can damage the surface. Finally, it is relatively inexpensive compared to other alternatives.

How to Apply Concrete Floor Epoxy Filler

Applying concrete floor epoxy filler is fairly simple but must be done correctly in order for the product to bond properly and provide the desired protection. First, the area must be thoroughly cleaned of any dirt, dust or debris. Next, any cracks or holes should be filled with an appropriate filler product prior to applying the epoxy filler. Once the area is prepped, the product can then be applied using a brush or roller depending on the size of the area being covered. Once the epoxy filler has been applied, it should be allowed to dry completely before being exposed to foot traffic or other activities.

FAQs About Concrete Floor Epoxy Filler

Q: What types of surfaces can I use concrete floor epoxy filler on?

A: Concrete floor epoxy filler can be used on both interior and exterior surfaces including concrete driveways, patios, sidewalks and garage floors.

Q: How long does it take for the epoxy filler to dry?

A: The drying time will depend on the temperature and humidity of the area where the product was applied but typically takes between 24-48 hours before the surface can be exposed to foot traffic or other activities.

Q: How often should I reapply concrete floor epoxy filler?

A: The frequency of reapplication will depend on the amount of wear and tear that the surface receives but typically every 1-2 years should suffice for most applications.

Q: Is there a way to speed up the drying process?

A: Yes, you can use a fan or dehumidifier to help speed up the drying process but make sure not to use too much air flow as this could cause bubbles in the product which could affect its performance.

Conclusion

Concrete floor epoxy filler is an excellent product for filling in cracks and other imperfections in concrete surfaces. It provides a strong bond that won’t crack or chip over time and provides protection from water, oil and other contaminants that can damage the surface. Applying concrete floor epoxy filler is relatively easy but does require some preparation prior to application in order for it to bond properly and provide optimal performance. With proper care and maintenance, this product will last for years providing a smooth, even finish that will look great and protect your concrete surfaces from wear and tear over time.