Nevertheless, the performance as well as visual appeal of concrete may be hampered by the practical safety aspects of its, particularly for kids that are young . When utilized in basements, possessing bare concrete floors is an even more hygienic alternative from moldy carpets & rugs.

Images about Concrete Floor Thickness Industrial

Concrete Floor Thickness Industrial

price which is Low, little maintenance and durability make this the ideal flooring option for industrial, commercial as well as other high traffic scenarios. With this particular technological innovation of concrete floors, the floor is kept warm even in probably the coldest climate and you are able to hike on the floor even with no shoe.

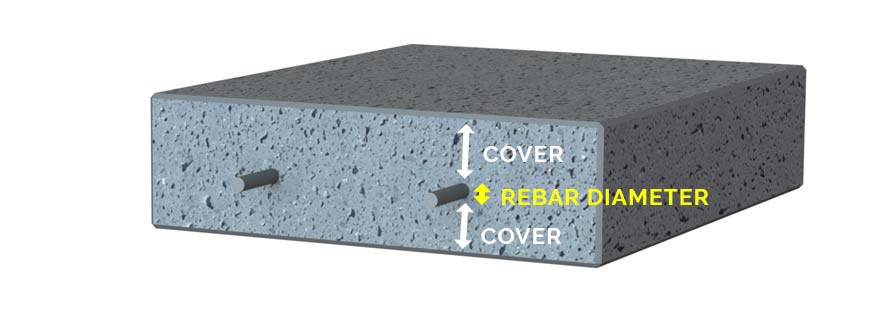

How Thick is a Commercial Concrete Slab? Concrete Reinforcement

Even if you might be ready to keep your floor war with radiant floor heating installed, if you do not have this choice and concrete flooring is usually a bit cold. Polished concrete floors, lengthy consigned to business-related spaces as well as finished basements, are creating well-deserved inroads into residential homes.

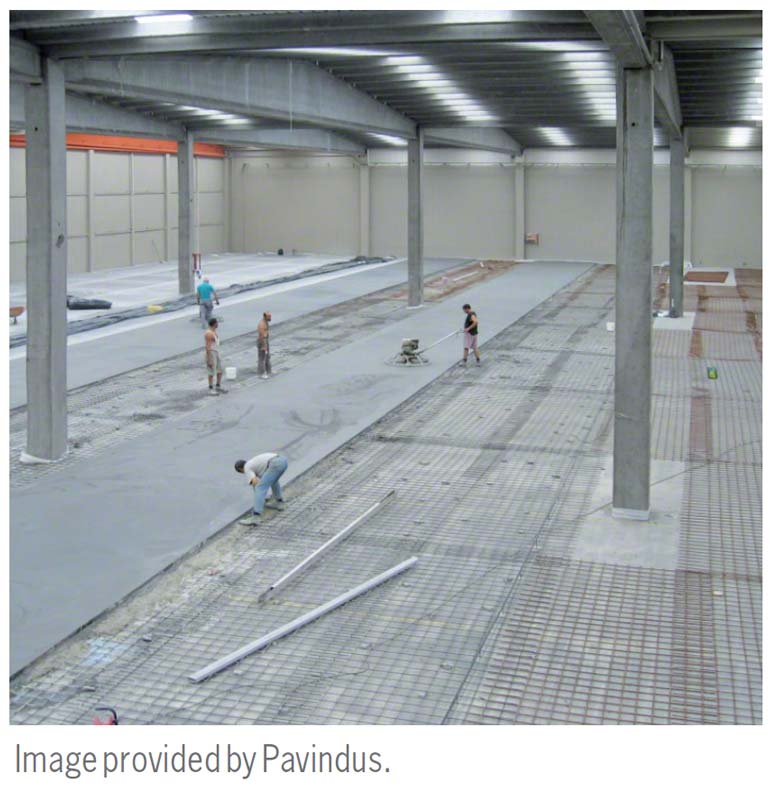

How to Design an Ideal Floor for Warehouse and Logistics Facilities

Concrete Floor Thickness for Heavy Equipment – Hansen Buildings

Lightweight Concrete Floor Systems – Thickness, Uses – The Constructor

Concrete Slab on Grade Analysis Calculator (for Post or Wheel Loading)

Concrete Floor Slabs Concrete Construction Magazine

How Thick Should a Concrete Slab be? – The Constructor

Minimum Thickness of Concrete Elements Heaton Manufacturing

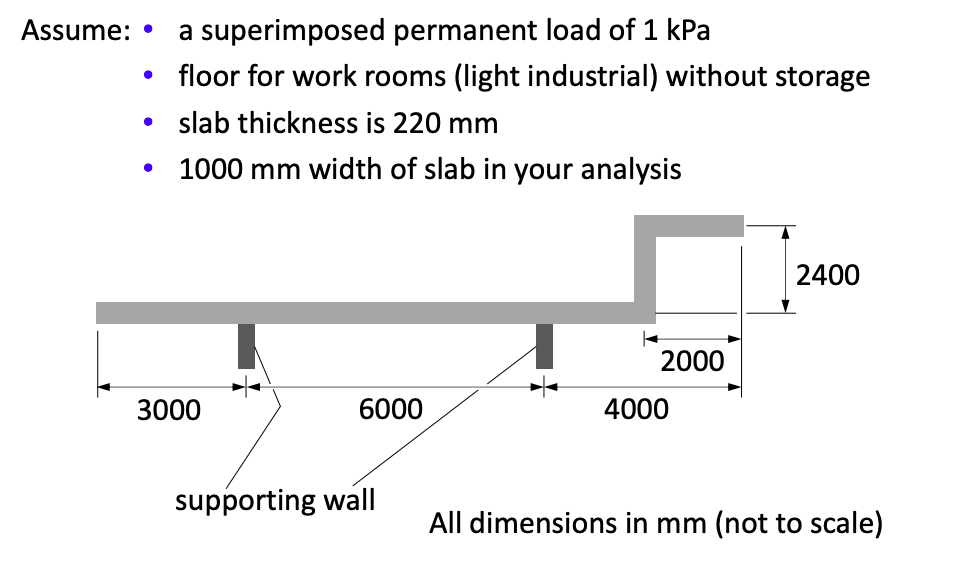

Consider the stepped concrete floor structure shown Chegg.com

Concrete slabs and concrete products for warehouses Maccaferri

How to Determine Concrete Slab Thickness Why You Need To Know

Concrete: Slab Thickness » Alpha Paving

Warehouse flooring – Interlake Mecalux

Related Posts:

- High Gloss Concrete Floor Sealer

- Concrete Floor Finishes

- Tinted Concrete Floors

- Concrete Floor Refinishing DIY

- Concrete Floor For Garage

- Concrete Floor Cleaning Tips

- DIY Concrete Floor Paint

- Gray Concrete Floor Paint

- Concrete Floor Cleaning Solution

- Redo Concrete Floors

Introduction to Concrete Floor Thickness Industrial

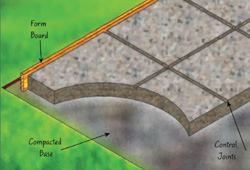

Concrete floor thickness industrial is a process of pouring concrete over a pre-existing floor or substrate. It is a popular method used by many industries to create a durable, long-lasting surface. This method is typically used in warehouses, factories, and commercial buildings. Concrete floor thickness industrial is also ideal for creating flat surfaces in any space such as a restaurant, retail store, or office building. In this article, we will discuss the different types of concrete floors, the benefits of using concrete floor thickness industrial, and the typical steps involved in the process.

Types of Concrete Flooring

There are two main types of concrete flooring that can be used in an industrial setting: poured-in-place and precast. Poured-in-place concrete is poured directly onto the existing substrate by a team of experienced installers. This type of flooring provides a stronger bond to the substrate, making it more resilient to wear and tear. Precast concrete is created offsite in a factory and then delivered to the site for installation. This type of flooring is often more cost effective than poured-in-place since it eliminates the need for onsite labor.

Benefits of Concrete Floor Thickness Industrial

Concrete floor thickness industrial is an excellent option for creating durable floors that will last for years to come. Concrete has a high resistance to wear and tear, making it ideal for industrial settings that experience high levels of foot traffic. Additionally, concrete flooring has an extremely low maintenance cost and can be easily cleaned with soap and water. The installation process is also relatively simple and can usually be completed within one day. Finally, concrete floors can provide thermal insulation benefits which can help to reduce energy costs in buildings.

Typical Steps Involved in the Process

The installation process for concrete floor thickness industrial typically involves several steps. First, the area must be prepared by clearing away any debris or obstacles that may be present. Next, the subfloor must be inspected for any damage and repaired if necessary. After this step is completed, the area should be leveled with a self-leveling compound before the concrete mix is poured into place. Once all of these steps are complete, the mix should be allowed to cure for at least 24 hours before it can be walked on or covered with a top coat sealant.

FAQs about Concrete Floor Thickness Industrial

Q: What are the advantages of using concrete floor thickness industrial?

A: The main advantages of using concrete floor thickness industrial include its durability, low cost of maintenance, simplicity of installation process, and thermal insulation benefits. Additionally, concrete floors are easy to clean and resistant to wear and tear which makes them ideal for industrial areas with high levels of foot traffic.

Q: How long does it take to install concrete floor thickness industrial?

A: The time it takes to install concrete floor thickness industrial will depend on several factors such as the size of the area being covered and the complexity of the job. Generally speaking, however, most installations can be completed within one day.

Q: What type of sealant should I use on my concrete floor?

A: After your concrete floor has been installed and allowed to cure for at least 24 hours, you should apply a top coat sealant to protect it from dirt and moisture. There are many different types of sealants available so it’s important to choose one that is specifically designed for use on concrete floors in order to ensure optimal performance.