Epoxy concrete floor repair is a crucial process for maintaining the longevity and appearance of concrete surfaces, especially in high-traffic areas like garages, warehouses, and industrial facilities. Over time, concrete floors can develop cracks, chips, and other forms of damage due to wear and tear, heavy loads, or exposure to harsh chemicals. Repairing these imperfections with epoxy not only restores the structural integrity of the floor but also prevents further deterioration. Epoxy is an ideal material for concrete repair because it bonds tightly with the existing concrete, creating a seamless, durable, and aesthetically pleasing surface that can withstand the rigors of daily use.

Images about epoxy concrete floor repair

Epoxy concrete floor repair

Advantages of Using Epoxy for Concrete Floor Repair

Epoxy offers several key advantages when it comes to repairing concrete floors. One of the most significant benefits is its strong adhesive properties, which allow it to bond effectively with the concrete substrate, filling in cracks and leveling out uneven surfaces. This bond creates a monolithic surface that is resistant to further cracking or damage. Additionally, epoxy is highly durable and resistant to chemicals, oil spills, and moisture, making it an ideal solution for areas prone to such exposures. The material’s flexibility also allows it to expand and contract with the concrete as temperatures fluctuate, reducing the likelihood of future cracks. Furthermore, epoxy’s self-leveling properties ensure a smooth, even finish that enhances the floor’s overall appearance.

The Repair Process and Considerations

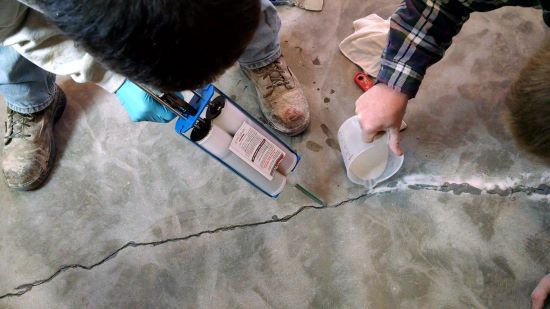

Repairing a concrete floor with epoxy involves several important steps, each of which must be carefully executed to achieve a successful outcome. The process typically begins with a thorough cleaning of the damaged area to remove any debris, dust, or loose particles. Next, cracks and holes are filled with a specialized epoxy repair compound, which is then smoothed out to ensure an even surface. In cases of larger damage, a multi-layer approach may be required, with each layer allowed to cure before applying the next. After the repair material has fully cured, the entire floor can be coated with an epoxy finish, which not only seals the repairs but also provides additional protection and a uniform appearance. It’s important to follow the manufacturer’s instructions regarding mixing ratios, application techniques, and curing times to ensure the repair is both effective and long-lasting.

Long-Term Maintenance and Prevention

While epoxy concrete floor repair can effectively restore damaged floors, ongoing maintenance is essential to prolong the life of the repaired surface. Regular cleaning is important to prevent dirt, debris, and chemicals from accumulating and potentially damaging the epoxy coating. For areas exposed to heavy loads or frequent traffic, applying a protective topcoat can provide an additional layer of defense against wear and tear. It’s also advisable to inspect the floor periodically for any new signs of damage, such as small cracks or chips, and address these issues promptly before they worsen. By combining quality epoxy repair with proper maintenance, homeowners and businesses can enjoy a durable, attractive concrete floor that stands the test of time.

Perfect Patch Mr O Chem

Introducing Sika Injectokit TH Concrete Crack Repair System

How to Repair Concrete with Epoxy Injection Techniques (NEW)

DIY Epoxy Garage Floor Coating Repair – Casper, WY

Epoxy Cement Guide – Applications and Concrete Repair with Epoxy

Related Posts:

- High Gloss Concrete Floor Sealer

- Concrete Floor Finishes

- Tinted Concrete Floors

- Concrete Floor Refinishing DIY

- Concrete Floor For Garage

- Concrete Floor Cleaning Tips

- DIY Concrete Floor Paint

- Gray Concrete Floor Paint

- Concrete Floor Cleaning Solution

- Redo Concrete Floors

Epoxy Concrete Floor Repair: All You Need to Know

Epoxy concrete floor repair is an effective and reliable way of fixing concrete flooring that has been damaged or worn away over time. Whether it’s a crack, hole, or chipped area, epoxy concrete floor repair can restore your floor to its previous strength and beauty. In this article, we will discuss the basics of epoxy concrete floor repair, the benefits of using it, and the steps you need to take in order to do it correctly.

What is Epoxy Concrete Floor Repair?

Epoxy concrete floor repair is a process of using an epoxy resin to fill in cracks and holes in a concrete floor. The epoxy mixture is made up of two components – a resin and a hardener – which are mixed together to create a strong, durable bond that will hold up against wear and tear as well as moisture. The epoxy is applied to the damaged area like a paste and cures to form a solid, waterproof seal.

Benefits of Using Epoxy Concrete Floor Repair

There are many benefits to using epoxy concrete floor repair, including:

– Durable: Epoxy concrete floors are known for their durability, as they are resistant to water and wear and tear.

– Cost-Effective: Epoxy concrete floor repair is much more cost-effective than replacing the entire floor.

– Quick: The epoxy mixture is easy to mix and apply, meaning that you can get your floor repaired quickly without having to wait for materials or labor.

– Versatile: Epoxy concrete floor repair can be used on any type of concrete surface, from driveways and patios to sidewalks and basements.

How to Repair Your Concrete Floor With Epoxy

When it comes to repairing your concrete floor with epoxy, there are several steps you need to take in order to get the job done correctly:

1. Clean the Area: Clean the damaged area with a broom or brush and remove any debris or dirt that may be present.

2. Prepare the Surface: Use an abrasive stone or grinder to smooth out any jagged edges around the area. This will help ensure that the epoxy adheres properly.

3. Mix the Epoxy: Follow the instructions on your epoxy package carefully when mixing the epoxy resin and hardener together. Be sure to mix thoroughly until all lumps are gone.

4. Apply the Epoxy: Use a putty knife or spatula to spread the mixed epoxy into the damaged area. Be sure to cover all parts of the area completely.

5. Allow to Cure: Allow the epoxy to cure for at least 24 hours before walking on it or applying any other coatings or sealants.

6. Finish: Once cured, you can finish off your repaired area by applying a sealant or waxing it for extra protection against wear and tear.

Can I use epoxy concrete floor repair on my driveway?

Yes, epoxy concrete floor repair can be used on driveways as well as other types of concrete surfaces such as patios and sidewalks. Just be sure to follow all instructions when mixing and applying the epoxy in order for it to adhere properly.

How long does it take for epoxy concrete floor repair to cure?

Generally speaking, epoxy concrete floor repair takes around 24 hours to cure completely before you can walk on it or apply any other coatings or sealants. However, this can vary depending on the temperature and humidity conditions in your area, so it’s best to check with your local building codes before proceeding with any repairs.