What You Need to Know Before Beginning an Epoxy Floor Project

Starting a DIY epoxy floor project in your garage is exciting, but it’s essential to be well-prepared to get the best results. Epoxy floors are durable and long-lasting, and add a professional look to any garage. Before you dive in, there are several key things to know that will help ensure your project goes smoothly and your new floor lasts for years.

- Understand the Commitment

Applying an epoxy floor isn’t a one-day project. It involves several steps, including cleaning, prepping, applying, and curing. You’ll need to set aside at least a weekend, and in some cases, it could take longer, depending on drying times and weather conditions. Being aware of this from the start helps you plan better and avoid rushing through any steps. - Know Your Garage’s Needs

Different garages have different requirements. If your garage is a high-traffic area or you work on cars frequently, you might need a thicker, more durable epoxy. Understanding your usage will help you choose the best epoxy type and finish, ensuring it stands up to your lifestyle. - Check the Weather Forecast

Weather conditions, especially humidity and temperature, play a big role in how well the epoxy adheres and cures. Ideal conditions are typically between 60-85°F with low humidity. Avoid starting the project if it’s raining or extremely humid, as moisture can interfere with epoxy bonding. - Prepare for Strong Fumes

Epoxy products can release strong odors during application, especially in an enclosed space like a garage. It’s important to have good ventilation, so open all windows and doors if possible. A mask is also essential for personal protection, ensuring you’re not breathing in any fumes directly. - Consider the Investment

While DIY epoxy kits are cheaper than hiring a professional, they can still be a bit of an investment, especially if you opt for high-quality epoxy. Beyond the epoxy itself, there are additional materials like rollers, brushes, and cleaning solutions to factor into the budget. - Understand Potential Challenges

DIY epoxy floors can be challenging, especially if the concrete is damaged or heavily stained. Repairing cracks, removing old coatings, and ensuring a clean surface can add extra time to the project. Knowing this in advance will help you set realistic expectations for your DIY journey.

Choosing the Right Epoxy: Types, Colors, and Finishes for Garage Floors

Selecting the right epoxy is essential for getting the look and durability you want for your garage floor. There are several types, colors, and finishes to choose from, each with its pros and cons. Here’s how to navigate your options to make the best choice.

Types of Epoxy: Water-Based vs. Solvent-Based vs. 100% Solid

Epoxies come in different formulations, with water-based being more user-friendly and solvent-based offering greater durability but stronger fumes. For maximum durability, 100% solid epoxy is often preferred. However, this type is harder to apply and generally more expensive.

Color Options: From Neutral Tones to Bold Choices

Epoxy floor colors vary from classic grays and whites to bold reds and blues. Neutral tones are popular for a clean, professional look, while brighter colors can make your garage feel more personalized. Just remember, darker colors can show dust and dirt more quickly.

Add Color Flakes for a Unique Look

Color flakes are a great way to add texture and visual interest to your epoxy floor. They can make your floor look like polished granite, while also providing a bit of slip resistance. These flakes come in various colors and can be sprinkled as sparsely or as densely as you prefer.

Gloss Level: Matte, Satin, or High Gloss

Epoxy finishes range from matte to high gloss. A glossy finish offers a sleek look and reflects light, which can help brighten up the garage. Matte or satin finishes give a more understated appearance and hide minor imperfections, making them popular for high-traffic areas.

Consider UV Resistance for Longevity

If your garage receives a lot of sunlight, look for an epoxy with UV resistance to prevent yellowing over time. Some epoxies are designed for exterior use and are more resistant to sunlight, making them a good choice for bright garages.

Clear Topcoat for Extra Protection

Adding a clear epoxy topcoat over the colored layer adds extra durability and protection. A top coat can make the surface more resistant to chemicals, oil, and scratches, extending the life of your floor and keeping it looking new.

Essential Tools and Materials: A Complete Checklist for Your DIY Epoxy Floor

Having the right tools and materials on hand can make or break your epoxy floor project. Preparation is key, so here’s a checklist of essentials that will help your DIY project go smoothly.

Epoxy Kit

Your epoxy kit will usually include both the resin and hardener. Make sure you choose a kit designed for garage floors, as these are specifically formulated for durability and chemical resistance. Measure your floor area accurately to ensure you purchase the right amount.

Concrete Cleaner and Degreaser

A clean surface is crucial for epoxy adhesion. Use a concrete cleaner and degreaser to remove any oil, grease, or dirt from the floor. This step is essential; even a little residue can prevent the epoxy from bonding properly.

Patch Kit for Cracks and Holes

If your garage floor has cracks or chips, you’ll need a concrete patch kit. Filling in these imperfections creates a smooth, even surface for the epoxy to adhere to. Uneven areas can make the epoxy look uneven, so this step is worth the extra effort.

Paint Roller with Extension Pole

A paint roller with an extension pole will allow you to apply the epoxy evenly and efficiently. Look for a roller cover with a 3/8 to 1/2 inch nap, as this thickness works well for epoxy. The extension pole will save your back and make the job much easier.

Safety Gear: Gloves, Mask, and Goggles

Working with epoxy involves chemicals that can be harmful if inhaled or touched. Wear gloves, a mask, and goggles to protect yourself during application. Epoxy can be tough to remove from the skin, so gear up accordingly.

Painter’s Tape and Plastic Sheeting

Use painter’s tape and plastic sheeting to cover walls, doors, and any areas you don’t want epoxy on. Epoxy can be hard to remove once it’s set, so take time to tape off all edges and protect surfaces that could get splashed.

Step-by-Step Preparation: Prepping Your Garage Floor for Epoxy Application

Properly prepping your garage floor is crucial for a successful epoxy application. Skipping or rushing through this step can lead to peeling or bubbling, so take your time to get it right. Here’s a step-by-step guide to prepping your floor.

Clear the Garage Completely

Start by removing everything from the garage. Move any items out of the way and give yourself plenty of workspace. Once the floor is empty, sweep it thoroughly to remove dust and debris, giving you a clear surface to work with.

Degrease the Floor

Degreasing is essential, as oil and other chemicals can prevent the epoxy from sticking. Apply a concrete degreaser and scrub the floor with a stiff brush, focusing on any stained areas. Rinse with clean water and let it dry completely.

Etch the Concrete for Better Adhesion

Etching roughens the concrete, making it easier for the epoxy to adhere. Use a concrete etching solution and follow the manufacturer’s instructions. This process is typically done by spreading the solution, scrubbing it in, and then rinsing it off thoroughly.

Patch Cracks and Holes

After etching, check for any cracks or holes. Use a concrete patch to fill these areas, smoothing them out as much as possible. Let the patches dry completely according to the product instructions before moving to the next step.

Perform a Moisture Test

Moisture can cause epoxy to peel, so it’s wise to test for it. Tape a small plastic sheet to the floor and leave it for 24 hours. If moisture forms under the plastic, it might be wise to reconsider or invest in a moisture barrier.

Sweep and Vacuum for a Final Clean

After all patches have dried, do a final sweep and vacuum the floor. Dust and debris can ruin the finish, so make sure the floor is as clean as possible. This will create a pristine surface for the epoxy to bond.

Applying Epoxy Like a Pro: Techniques for a Smooth, Even Finish

Applying epoxy requires attention to detail to achieve a smooth, even finish that will last. Although it may seem like simply rolling on paint, there are specific techniques that make a big difference in the outcome. Here’s how to apply epoxy like a pro.

Mixing the Epoxy Properly

Mixing epoxy involves combining the resin and hardener, and this step is crucial for the epoxy to cure correctly. Carefully follow the manufacturer’s instructions for the mixing ratio and timing. Use a drill with a mixing attachment to get a smooth, consistent mixture. Once mixed, be aware that epoxy starts curing, so you’ll need to work quickly.

Start in Small Sections

Epoxy can be difficult to work with because it sets relatively fast. Divide the garage floor into manageable sections, and work on one section at a time to ensure you’re applying the epoxy evenly. Starting at the back of the garage and moving toward the door will prevent you from painting yourself into a corner!

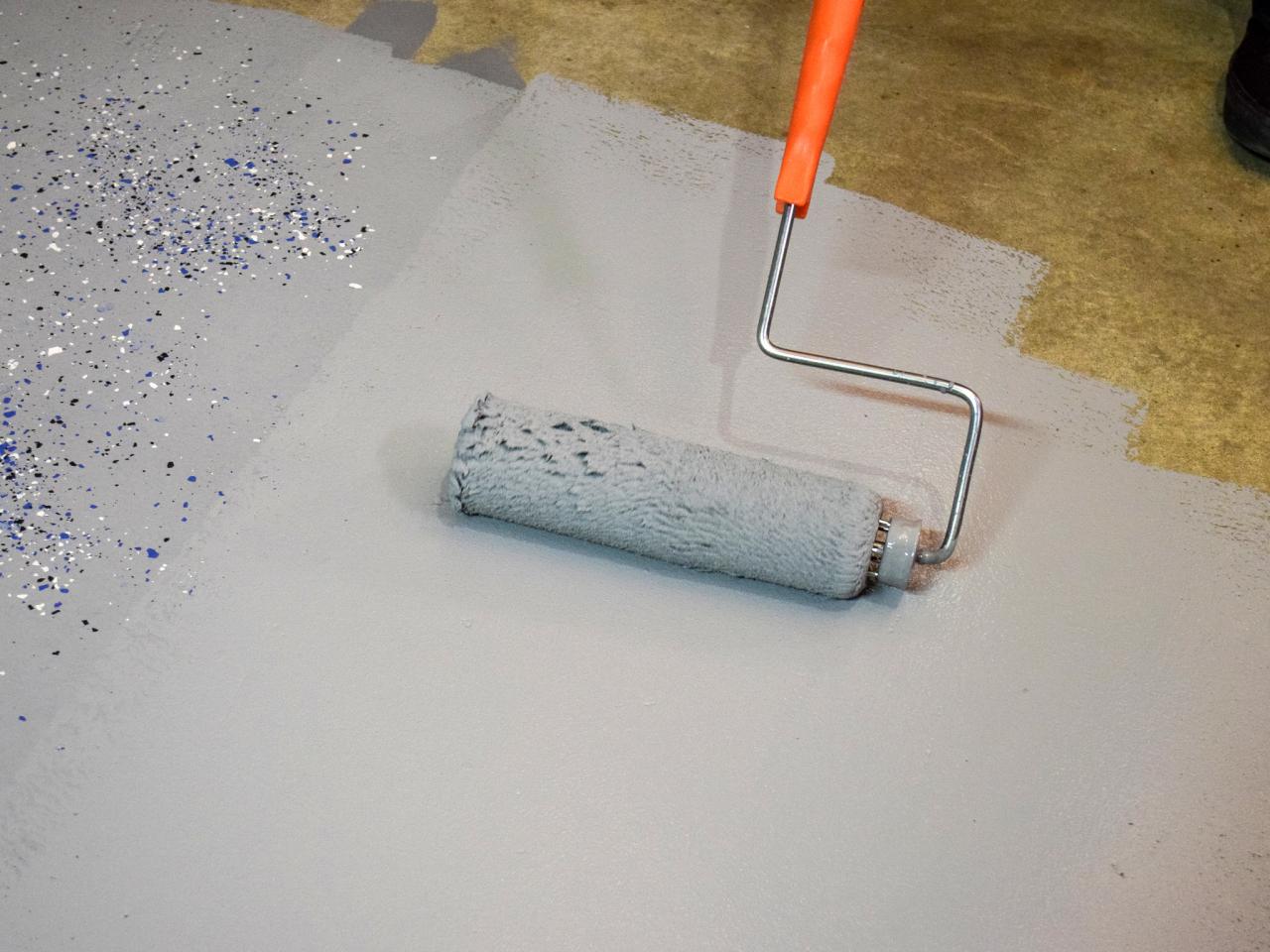

Use a Roller for Even Application

Using a paint roller with an extension pole is the easiest way to apply epoxy to large surfaces. Roll the epoxy in overlapping strokes to avoid leaving lines. Applying it this way also helps distribute the material evenly, preventing thick or thin spots that could lead to uneven curing.

Add Color Flakes or Anti-Slip Aggregate as Desired

If you’re adding color flakes for visual interest or anti-slip aggregate for traction, sprinkle these materials immediately after rolling out the epoxy in each section. This allows them to settle into the epoxy before it starts to cure. Aim to sprinkle evenly to get a balanced look and feel.

Use a Brush for Edges and Corners

A small paintbrush is ideal for applying epoxy around edges and in tight corners where a roller can’t reach. Work carefully to prevent drips or pooling along the edges, as these areas will take longer to cure if there’s excess material.

Allow the First Coat to Set Before Reapplying

Many epoxy floors require two coats for optimal coverage and durability. Allow the first coat to dry completely before applying the second coat. Waiting time varies depending on the product, but 12-24 hours is typical. A second coat ensures a stronger bond and a flawless, even surface.

Drying and Curing: How Long to Wait and Tips for Best Results

Drying and curing times are critical for a successful epoxy floor. Rushing this process can lead to a weak finish or surface imperfections. Here’s how to ensure your epoxy cures properly for a durable, high-quality result.

Understand the Difference Between Drying and Curing

Drying and curing are not the same thing. The epoxy might feel dry to the touch after a few hours, but full curing takes several days. Drying means the surface is no longer tacky, while curing means it has reached full hardness and durability. Follow the product’s recommendations to allow for both.

Check the Temperature and Humidity Levels

Curing time depends heavily on temperature and humidity. Epoxy cures best in warm, dry conditions, typically around 70°F with low humidity. Higher humidity can slow the curing process and may lead to a cloudy finish. Try to choose a time when weather conditions are favorable, or use a dehumidifier if needed.

Avoid Walking on the Floor Prematurely

It’s tempting to step on your newly finished floor but avoid walking on it too soon. Most epoxies need at least 24 hours before light foot traffic and up to 72 hours before moving in heavy items. Premature use can lead to dents and imperfections, so resist the urge to test it out too soon.

Allow Extra Time for Heavy Use

For areas where you’ll be placing heavy machinery, cars, or workbenches, wait at least a full week to ensure the epoxy is fully cured. While this might seem like a long time, it’s worth the wait to avoid any pressure marks or damage.

Ventilate for Better Curing

Good ventilation can speed up the curing process and help with odor removal. If possible, keep garage doors and windows open. Avoid using fans, though, as they can stir up dust and other particles that may settle on your freshly coated floor.

Perform a Final Inspection

Before moving items back in, inspect the floor for any soft spots or tacky areas that indicate incomplete curing. It’s better to wait an extra day or two than to risk damage. Once it’s fully cured, your floor will be ready for years of use.

Maintaining Your Epoxy Floor: Cleaning and Care Tips for Longevity

A little regular maintenance goes a long way in keeping your epoxy garage floor looking new and performing well. Epoxy is durable, but like any surface, it benefits from care to prevent wear and damage. Here are some tips for maintaining your floor’s longevity.

Sweep and Dust Regularly

Regular sweeping prevents dust and debris from scratching the epoxy surface. A soft broom or dust mop works well for keeping the floor clear, especially in high-traffic areas. If you work on cars or projects in the garage, frequent sweeping will keep the surface in top shape.

Wipe Up Spills Quickly

Although epoxy is resistant to most chemicals and stains, it’s still a good idea to wipe up spills promptly. Motor oil, gasoline, or other chemicals can discolor the floor over time if left sitting. A quick wipe with a cloth or paper towel is usually enough to prevent any issues.

Use a Mild Cleaner for Deeper Cleaning

For regular cleaning, a mix of water and a pH-neutral cleaner works well on epoxy floors. Avoid harsh chemicals like bleach or ammonia, which can degrade the finish over time. Mopping with a mild cleaner once a month is usually sufficient to keep the floor looking clean and polished.

Avoid Abrasive Tools or Cleaners

Steer clear of abrasive tools, brushes, or harsh cleaning agents that could scratch the epoxy. Instead, use a soft sponge or mop for any stubborn spots. If you need to scrub, do so gently and use a non-abrasive cleaner designed for epoxy or similar surfaces.

Protect High-Traffic Areas with Rugs or Mats

Placing rubber mats or rugs in high-traffic areas, especially near entrances, can extend the life of your epoxy floor. These mats can trap dirt and absorb minor spills, reducing the wear on the epoxy and keeping the floor cleaner overall.

Reapply a Topcoat for Longevity

Some epoxy floors may benefit from a new clear topcoat after a few years, especially if you notice signs of wear. A topcoat helps refresh the shine, adds another layer of protection, and keeps the epoxy looking new. This additional coat can extend the life of your floor and maintain its durability.

DIY vs. Professional Garage Floor Coatings

Coatings Pro v. DIY Epoxy Garage Floor Kits

How Much Does It Cost To Epoxy Garage Floor?

DIY Epoxy Garage Floor Coating Repair

How to Epoxy Your Garage Floor

Related Posts: