Understanding the Effects of Cold Weather on Epoxy Garage Floors

Epoxy garage floors have become increasingly popular due to their durability and aesthetic appeal. However, it’s crucial to understand the effects of cold weather on epoxy coatings to ensure their longevity. Cold temperatures can impact the curing process, adhesion, and overall performance of the epoxy. let’s talk about the specific effects of cold weather on epoxy garage floors.

- Curing Process: Cold weather significantly affects the curing process of epoxy coatings. Epoxy requires a specific temperature range for proper curing. In colder temperatures, the curing time may be extended, leading to a longer wait before you can use your garage. It’s essential to adhere to the manufacturer’s instructions regarding temperature requirements for curing.

- Adhesion Issues: Cold weather can also impact the adhesion of epoxy coatings. If the temperature is too low, the epoxy may not bond properly to the concrete surface, resulting in a weaker and less durable coating. It’s crucial to ensure that the temperature is within the recommended range to achieve optimal adhesion.

- Moisture Problems: Cold weather often comes with increased humidity and moisture. Moisture can be detrimental to the epoxy curing process and result in a cloudy or hazy appearance. Before applying epoxy in cold weather, it’s crucial to ensure that the surface is dry and free from moisture. Proper moisture testing and preparation are essential to prevent any issues.

- Temperature Fluctuations: One of the challenges of cold weather is the fluctuation in temperatures. Freezing and thawing cycles can cause the epoxy to expand and contract, leading to cracks and delamination. It’s important to choose an epoxy product that can withstand these temperature fluctuations to ensure long-term durability.

- Prevention and Solutions: To minimize the effects of cold weather on epoxy garage floors, there are a few preventive measures you can take. Ensure that the garage is properly insulated to maintain a stable temperature. Use a space heater or heat lamps to warm up the garage before applying epoxy. Additionally, consider using an epoxy product specifically formulated for cold weather conditions.

Preparing Your Garage for Epoxy Coating in Cold Temperatures

Preparing your garage for epoxy coating is essential to ensure a successful application and long-lasting results. When it comes to applying epoxy in cold temperatures, proper preparation becomes even more critical. Let’s discuss the necessary steps to prepare your garage for epoxy coating in cold weather conditions.

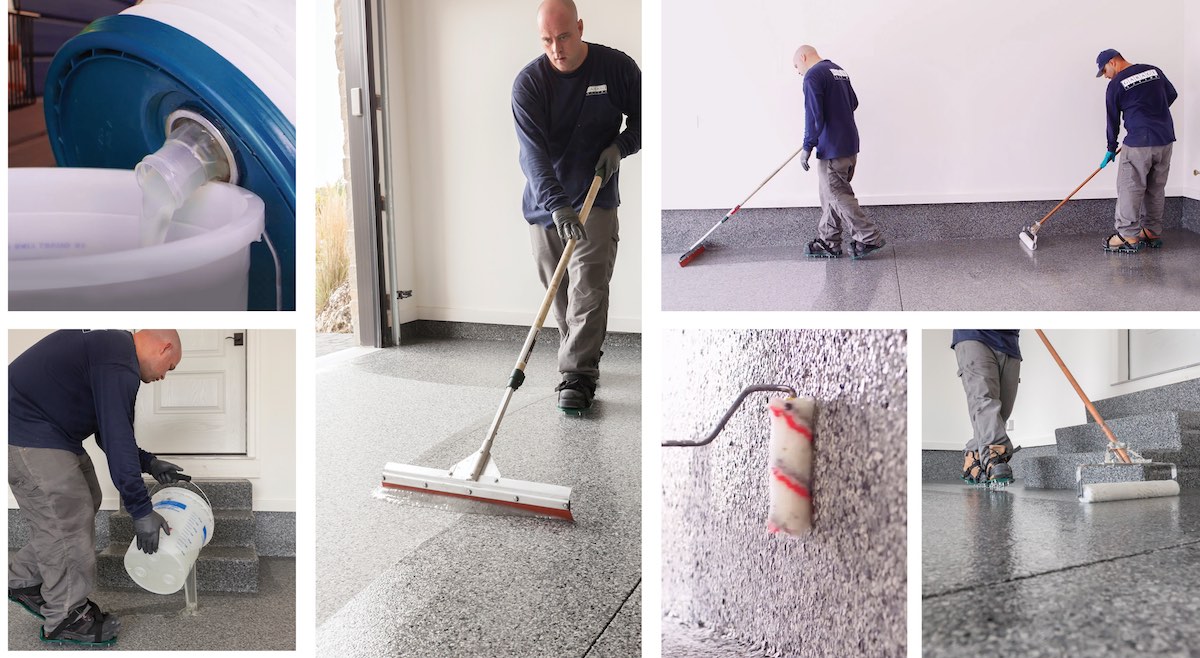

- Cleaning the Surface: Before applying epoxy, it’s crucial to thoroughly clean the garage floor surface. Remove any dirt, oil, grease, or other contaminants that may hinder proper adhesion. Use a degreaser or a suitable cleaning solution and scrub the floor with a stiff brush or a floor scrubber. Rinse the surface thoroughly and allow it to dry completely before proceeding.

- Repairing Cracks and Imperfections: Inspect the garage floor for any cracks, holes, or imperfections. These should be repaired before applying epoxy to ensure a smooth and even coating. Use a suitable concrete patching compound to fill in any cracks or holes. Smooth out the patched areas and allow them to cure according to the manufacturer’s instructions.

- Etching the Surface: Etching the garage floor is an important step in preparing it for epoxy coating. Etching helps create a rough surface that enhances the adhesion of the epoxy. In cold weather, it’s crucial to choose an etching product that is compatible with low temperatures. Follow the manufacturer’s instructions for application and ensure proper ventilation during the process.

- Moisture Testing: Moisture can compromise the adhesion and longevity of epoxy coatings. Before applying epoxy in cold temperatures, it’s essential to perform a moisture test to ensure that the concrete surface is dry. There are various moisture testing methods available, including calcium chloride tests and relative humidity tests. Choose the appropriate method and follow the instructions to determine the moisture content of the floor.

- Temperature and Humidity Control: In cold weather, it’s important to control the temperature and humidity levels in the garage during the epoxy application process. Ensure that the garage is heated to the recommended temperature range specified by the epoxy manufacturer. Use space heaters or heat lamps to warm up the area and maintain a stable temperature. Additionally, monitor and control the humidity levels to prevent moisture-related issues.

Tips for Applying Epoxy in Cold Weather Conditions

Applying epoxy in cold weather conditions requires proper planning and execution to ensure successful results. Cold temperatures can affect the curing process, adhesion, and overall performance of epoxy coatings. Let’s discuss some valuable tips for applying epoxy in cold weather conditions.

Choose the Right Epoxy Product: Not all epoxy products are suitable for cold weather conditions. It’s essential to choose an epoxy product specifically formulated for low temperatures. These products are designed to cure and adhere properly in colder environments. Read the manufacturer’s guidelines and select an epoxy that is recommended for cold weather applications.

Check the Temperature Requirements: Before applying epoxy, carefully review the temperature requirements specified by the manufacturer. Ensure that the ambient temperature and the temperature of the concrete surface are within the recommended range. Use a reliable thermometer to measure the temperature accurately.

Warm up the Garage: In cold weather, it’s crucial to warm up the garage before applying epoxy. Use space heaters or heat lamps to raise the temperature and create an optimal environment for epoxy application. It’s important to maintain a stable temperature throughout the curing process to achieve the best results.

Extend the Curing Time: In colder temperatures, the epoxy curing time may be longer than usual. It’s important to be patient and allow ample time for the epoxy to cure properly. Rushing the curing process can lead to subpar results. Follow the manufacturer’s instructions regarding curing times and avoid using the garage until the epoxy has fully cured.

Monitor Humidity Levels: Cold weather often comes with increased humidity levels. Moisture can interfere with the epoxy curing process and affect the overall performance of the coating. Use a dehumidifier to control the humidity levels in the garage during the epoxy application and curing process. This will help ensure a successful outcome.

The Best Epoxy Products for Cold Climate Garage Floors

Choosing the right epoxy product is crucial for achieving a long-lasting and durable garage floor coating, especially in cold climate regions. Cold temperatures can impact the curing process, adhesion, and overall performance of epoxy coatings. Below are some of the best epoxy products specifically designed for cold-climate garage floors.

Epoxy with Low-Temperature Curing: Look for epoxy products that have low-temperature curing capabilities. These types of epoxy coatings are formulated to cure properly even in colder temperatures. They provide excellent adhesion and durability, even in suboptimal weather conditions. Check the manufacturer’s specifications to ensure the epoxy is suitable for your specific climate.

High Solids Epoxy: High solids epoxy coatings are known for their superior performance in harsh conditions. These coatings have a higher percentage of solids, which translates to increased durability and resistance to temperature fluctuations. High-solid epoxy products are an excellent choice for cold-climate garage floors, as they can withstand the challenges posed by freezing and thawing cycles.

Moisture-Tolerant Epoxy: In cold climate regions, moisture can be a significant concern when it comes to epoxy garage floors. Moisture-tolerant epoxy coatings are designed to withstand moisture-related issues and still provide a strong and durable finish. Look for epoxy products that have moisture tolerance properties and can effectively resist the negative effects of moisture.

Chemical-Resistant Epoxy: If you anticipate exposure to chemicals in your garage, it’s essential to choose a chemical-resistant epoxy product. Cold-climate garage floors often encounter deicing salts, antifreeze, and other chemicals brought in from the outside. Chemical-resistant epoxy coatings are designed to withstand these substances without compromising their performance or appearance.

UV-Stable Epoxy: Although cold climate regions may not experience intense sunlight year-round, UV stability is still an important factor to consider. UV-stable epoxy coatings retain their color and gloss even when exposed to sunlight. This ensures that your garage floor remains vibrant and aesthetically appealing, regardless of the weather conditions.

Maintaining and Protecting Your Epoxy Garage Floor During Winter Months

Winter months can be particularly challenging for maintaining and protecting your epoxy garage floor. Cold temperatures, moisture, and deicing salts can all impact the performance and appearance of the coating. Let’s discuss some essential tips for maintaining and protecting your epoxy garage floor during the winter months.

Regular Cleaning: Regular cleaning is crucial for maintaining the appearance and longevity of your epoxy garage floor during winter. Sweep or vacuum the floor regularly to remove dirt, salt, and debris that can scratch the surface. Use a mild detergent and warm water to mop the floor occasionally and remove any stains or spills promptly.

Avoid Deicing Salts: Deicing salts, such as calcium chloride or rock salt, can damage the epoxy coating on your garage floor. These salts can cause discoloration, pitting, and even delamination of the epoxy. Avoid using deicing salts on your driveway or walkways, as they can be tracked into the garage. Instead, use sand or kitty litter for traction on slippery surfaces.

Place Mats or Rugs: To protect your epoxy garage floor from moisture and dirt brought in from outside, consider placing mats or rugs near entryways. These mats will help trap moisture and debris, preventing them from reaching the epoxy coating. Ensure that the mats have a non-slip backing to prevent any accidents.

Use Soft Bristle Brooms: When clearing snow or ice from your garage floor, use a soft bristle broom instead of a metal shovel or sharp-edged tool. Metal shovels can scratch and damage the epoxy coating. A soft bristle broom will effectively clear the snow without causing any harm to the surface.

Maintain Temperature and Humidity Levels: Maintaining temperature and humidity levels in your garage during the winter months is essential for protecting your epoxy garage floor. Cold temperatures and high humidity can lead to condensation and moisture-related issues. Install a dehumidifier in your garage to control the humidity levels and prevent excess moisture from accumulating. Additionally, consider using a space heater or insulated garage doors to maintain a stable temperature and prevent extreme fluctuations that can affect the epoxy coating.

Inspect for Damage: Regularly inspect your epoxy garage floor for any signs of damage or wear during the winter months. Look for cracks, chips, or areas where the epoxy may be lifting or delaminating. Promptly address any issues by repairing or recoating the affected areas to prevent further damage and maintain the integrity of the epoxy coating.

Avoid Abrasive Cleaning Methods: When cleaning your epoxy garage floor during the winter months, avoid using harsh or abrasive cleaning methods. Scrubbing with abrasive brushes or using strong chemicals can damage the epoxy coating. Instead, use a soft mop or microfiber cloth along with a mild detergent to gently clean the surface.

Apply a Protective Topcoat: Consider applying a protective topcoat over your epoxy garage floor during the winter months. A topcoat can provide an additional layer of protection against moisture, chemicals, and abrasion. There are various epoxy topcoat options available that are specifically designed to enhance the durability and performance of epoxy garage floors.

Address Spills and Stains Promptly: If you notice any spills or stains on your epoxy garage floor during the winter months, address them promptly. Wipe up any spills immediately to prevent them from seeping into the epoxy and causing discoloration or damage. For stubborn stains, use a mild cleaning solution and gently scrub the area with a soft brush.

Follow Manufacturer’s Recommendations: Lastly, always follow the manufacturer’s recommendations for maintaining and protecting your epoxy garage floor during the winter months. Each epoxy product may have specific guidelines and instructions for cleaning, maintenance, and protection. Adhering to these recommendations will help ensure the longevity and performance of your epoxy garage floor throughout the winter season.

The Garage Floor Winter Protection Solution Your Home Needs

Our Epoxy Garage Floor Coating: How Itu0027s Holding Up After 2

Applying Epoxy in Low temperatures: How to deal with cold weather

The Garage Floor Winter Protection Solution Your Home Needs

Can You Apply Coatings to Your Garage Floor During the Winter

Related Posts: