Understanding the Garage Floor Epoxy Dry Time

The dry time of garage floor epoxy is an important factor to consider when planning a flooring project. It determines when you can walk on the surface, move items back into the garage, or park your vehicles. Let’s discuss the garage floor epoxy dry time and what it means for your project.

- The Science Behind Garage Floor Epoxy Dry Time: Garage floor epoxy is a two-part coating that consists of resin and hardener. When these two components are mixed, a chemical reaction called curing takes place. During this curing process, the epoxy goes through various stages, including the gel stage, tack-free stage, and full cure stage. Understanding these stages is crucial to comprehending the epoxy dry time.

- Factors Influencing Garage Floor Epoxy Dry Time: Several factors can affect the drying time of garage floor epoxy. These include temperature, humidity, and the thickness of the epoxy application. Higher temperatures and lower humidity levels generally speed up the drying process, while colder temperatures and higher humidity can slow it down. Additionally, applying a thicker coat of epoxy may require more time to dry compared to a thin coat.

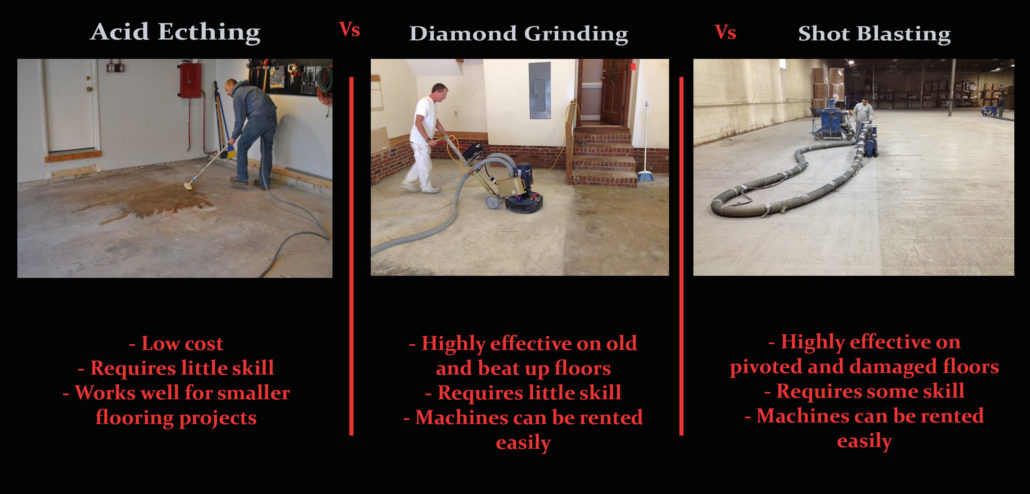

- The Importance of Proper Surface Preparation: Proper surface preparation plays a significant role in the epoxy dry time. It is essential to thoroughly clean the garage floor, remove any existing coatings, and repair any cracks or imperfections. A clean and smooth surface allows for better adhesion and ensures the epoxy dries evenly and within the expected time frame.

- Understanding Cure vs. Dry Time: It is crucial to differentiate between epoxy cure time and dry time. While the epoxy may feel dry to the touch within a few hours, it may take significantly longer to fully cure. Cure time refers to the duration required for the epoxy to reach its maximum hardness and durability. It is recommended to wait for the full cure time before subjecting the floor to heavy use or placing any objects on it.

- Testing the Dryness of Garage Floor Epoxy: To determine if the epoxy is dry and ready for the next step, you can perform a simple test. Press your thumb onto the surface firmly and then release. If the epoxy is dry, it should not leave an impression or feel sticky. If it feels tacky or leaves a mark, it indicates that the epoxy is not fully dry and needs more time to cure.

Factors Affecting Garage Floor Epoxy Dry Time

The dry time of garage floor epoxy can vary depending on various factors. It is essential to understand these factors as they can significantly impact the overall drying process. Below are the key factors that affect the garage floor epoxy dry time and provide you with valuable insights.

Temperature and Humidity: Temperature and humidity play a vital role in the drying time of garage floor epoxy. Generally, higher temperatures and lower humidity levels accelerate the drying process, while lower temperatures and higher humidity can slow it down. It is important to adhere to the recommended temperature and humidity guidelines provided by the epoxy manufacturer for optimal results.

Thickness of the Epoxy Application: The thickness of the epoxy application can affect the drying time. Applying a thicker coat of epoxy may require more time to dry compared to a thin coat. Thicker applications may also generate more heat during the curing process, which can impact the overall drying time. It is crucial to follow the manufacturer’s instructions regarding the recommended thickness of the epoxy application.

Mixing Ratio and Pot Life: Properly mixing the epoxy components is essential for achieving the desired drying time. Maintaining the correct mixing ratio ensures that the epoxy cures correctly and within the expected time frame. Additionally, the pot life, which refers to the time the epoxy remains workable after mixing, should be considered. It is crucial to work efficiently and complete the application before the pot life expires to avoid any issues with drying time.

Ventilation and Air Circulation: Adequate ventilation and air circulation can significantly impact the drying time of garage floor epoxy. Proper ventilation helps in expelling excess moisture and volatile organic compounds (VOCs) from the epoxy, allowing it to dry more efficiently. It is recommended to open windows and doors or use fans to facilitate air movement during the drying process.

Epoxy Brand and Product Specifications: Different epoxy brands may have variations in their product formulations and drying times. It is important to carefully read and follow the manufacturer’s instructions and specifications provided on the product packaging. Each epoxy product may have specific guidelines regarding drying time, temperature range, and other factors that should be considered for optimal results.

Tips and Tricks to Speed Up the Garage Floor Epoxy Dry Time

Waiting for the garage floor epoxy to dry can be a time-consuming process. However, several tips and tricks can help speed up the drying time and allow you to enjoy your newly coated floor sooner. Below are some effective strategies to expedite the garage floor epoxy dry time.

Optimize Temperature and Humidity Levels: One of the most effective ways to speed up the epoxy drying process is to create an ideal environment. Ensure that the temperature is within the recommended range provided by the epoxy manufacturer. Additionally, lower humidity levels can significantly accelerate the drying time. Use dehumidifiers or fans to reduce moisture in the air and create a drier environment.

Use a Fast-Curing Epoxy Product: Not all epoxy products have the same drying time. Some epoxy formulations are specifically designed for faster curing. When selecting an epoxy for your garage floor, consider choosing a fast-curing product. These types of epoxy often have additives or special formulations that promote quicker drying. Consult with the manufacturer or a professional to find the best fast-curing epoxy option for your project.

Thin Epoxy Application: Applying a thinner coat of epoxy can help expedite the drying time. Thicker applications take longer to dry as the epoxy needs more time to cure fully. Follow the manufacturer’s guidelines for the recommended thickness of the epoxy application. Using a roller with a shorter nap can also help achieve a thinner and more even coat.

Increase Air Circulation: Improving air circulation around the garage floor can aid in faster drying. Open windows and doors to allow fresh air to circulate. Use fans strategically to direct air towards the coated surface. Proper ventilation helps in removing excess moisture and expediting the evaporation process.

Use Heat Sources: Applying gentle heat to the epoxy-coated floor can accelerate the drying time. Use infrared heaters or space heaters to warm up the space. Be cautious not to use direct heat sources that can damage the epoxy or create hot spots. Maintain a consistent and moderate temperature to ensure proper curing.

Extend Cure Time: Although it may seem counterintuitive, extending the cure time can speed up the drying process. After the epoxy has dried enough to walk on, avoid placing heavy objects or subjecting the floor to any stress for an extended period. Allowing the epoxy to fully cure without any disturbances helps strengthen the coating and speeds up the overall drying time.

How Long Should You Wait for Garage Floor Epoxy to Dry?

Patience is essential when it comes to waiting for garage floor epoxy to dry. Rushing the process can lead to unsatisfactory results and damage to the coating. Let’s find out how long you should wait for garage floor epoxy to dry and the factors that affect the drying time.

Recommended Drying Time: The recommended drying time for garage floor epoxy can vary depending on the product and manufacturer. As a general guideline, epoxy typically takes around 24 to 72 hours to dry to the touch. However, it is important to note that this is not the same as full cure time. Full cure time refers to the duration required for the epoxy to reach its maximum hardness and durability, which can take several days to weeks.

Factors Influencing Drying Time: Several factors can affect the drying time of garage floor epoxy. Temperature, humidity, and the thickness of the epoxy application play significant roles. Lower temperatures and higher humidity levels can extend the drying time, while higher temperatures and lower humidity levels can accelerate it. Thicker epoxy applications may also require more time to dry compared to thinner coats.

Curing vs. Drying: It is crucial to understand the difference between curing and drying when it comes to garage floor epoxy. Drying refers to the time it takes for the epoxy to dry to the touch, where it is no longer tacky. Curing, on the other hand, refers to the time it takes for the epoxy to reach its maximum hardness and durability. While the epoxy may feel dry to the touch within a few hours, it is recommended to wait for the full cure time before subjecting the floor to heavy use or placing any objects on it.

Follow Manufacturer’s Instructions: To ensure the best results and avoid any issues with drying time, it is essential to follow the manufacturer’s instructions and recommendations. Each epoxy product may have specific guidelines regarding drying time, temperature range, humidity levels, and curing time. By adhering to these instructions, you can achieve optimal results and ensure the longevity of your garage floor coating.

Perform a Dryness Test: To determine if the epoxy is dry and ready for the next step, you can perform a simple dryness test. Gently press your thumb onto the surface and then release. If the epoxy is dry, it should not leave an impression or feel sticky. If it feels tacky or leaves a mark, it indicates that the epoxy is not fully dry and needs more time to cure. Performing this test in different areas of the floor can help ensure consistent drying throughout the entire surface.

Avoiding Common Mistakes

Avoiding common mistakes during the garage floor epoxy dry time is crucial to achieving optimal results and ensuring the longevity of the coating. We will discuss the best practices and common mistakes to avoid when it comes to the garage floor epoxy dry time.

Rushing the Drying Process: One of the most common mistakes is rushing the drying process. It can be tempting to start using the garage floor or moving items back in as soon as the epoxy feels dry to the touch. However, it is important to wait for the recommended drying and cure time provided by the manufacturer. Rushing the process can lead to premature damage, flaking, and a weakened coating.

Ignoring Proper Surface Preparation: Proper surface preparation is crucial for the success of the epoxy flooring project. Neglecting to thoroughly clean the garage floor, remove any existing coatings, or repair cracks and imperfections can affect the adhesion and drying time of the epoxy. Take the time to properly prepare the surface before applying the epoxy to ensure a smooth and even drying process.

Applying Epoxy in Unsuitable Conditions: Applying epoxy in unsuitable conditions can lead to issues with the drying time and overall quality of the coating. Avoid applying epoxy in extremely high or low temperatures, as it can affect the curing process. Additionally, high humidity levels can prolong the drying time and lead to improper adhesion. Follow the manufacturer’s guidelines regarding temperature and humidity range for optimal results.

Overlooking Ventilation and Air Circulation: Proper ventilation and air circulation are essential during the epoxy dry time. Lack of ventilation can trap excess moisture and prolong the drying process. Ensure that the space is well-ventilated by opening windows and doors or using fans to improve air circulation. This will help expel moisture and promote a faster and more even drying process.

Placing Heavy Objects Too Soon: Placing heavy objects on the epoxy-coated floor too soon can cause indentations and damage the coating. Even if the epoxy feels dry to the touch, it is crucial to wait for the recommended cure time before subjecting the floor to heavy use or placing heavy objects on it. Give the epoxy sufficient time to fully cure and reach its maximum hardness and durability.

Neglecting Regular Maintenance: Proper maintenance is essential to extend the life of your garage floor epoxy. Avoid using harsh cleaning agents or abrasive tools that can damage the coating. Regularly clean the floor using a mild detergent and a soft mop or cloth. By maintaining the epoxy coating, you can ensure its longevity and minimize the need for reapplication in the future.

What is the Curing Time for Epoxy Flooring? Epoxy Colorado

How to Prep Your Floor for an Epoxy Coating

How to Apply Epoxy Coating to a Garage Floor

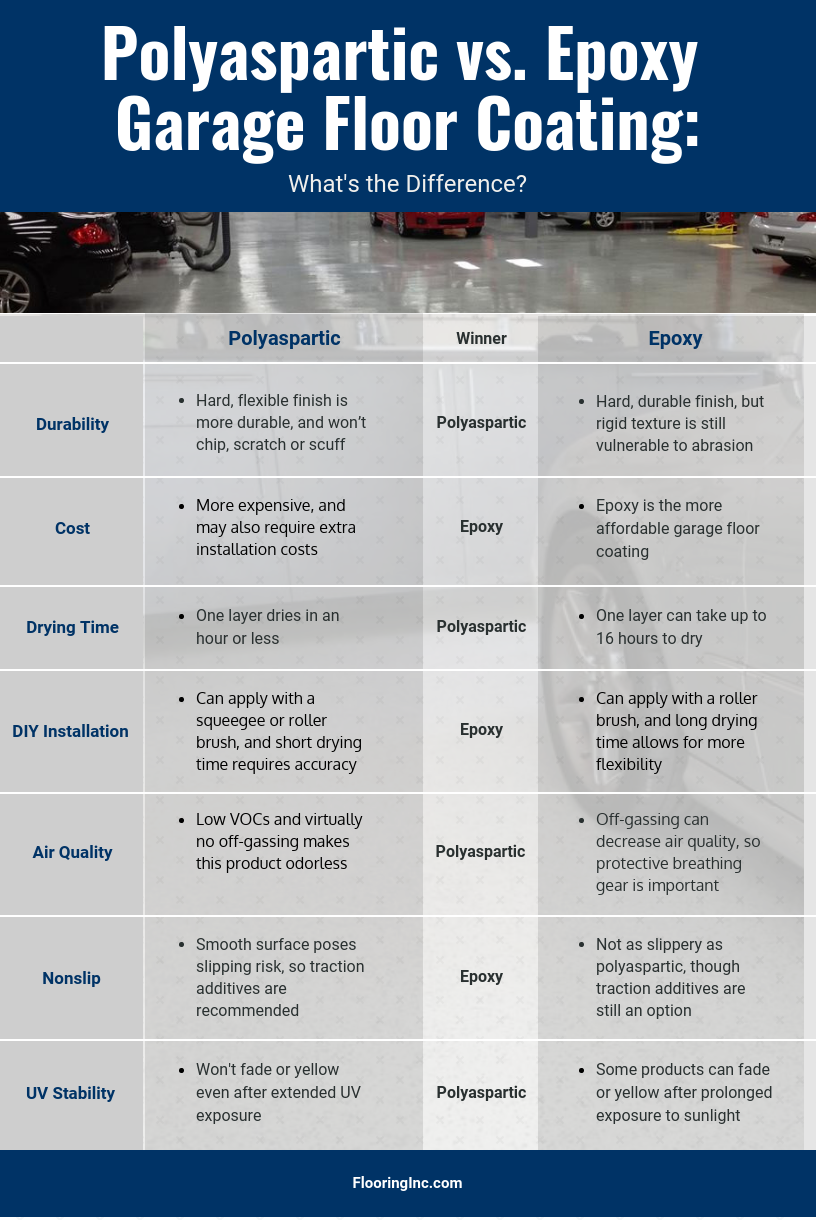

Polyaspartic vs. Epoxy Garage Floor Coating – Flooring Inc

Garage Floor Epoxy Everything you need to know BuyersAsk

How to Apply Garage Floor Epoxy Coatings The DIY Guide All

Related Posts: