What is Garage Floor Epoxy Sealer? Understanding the Basics

Garage floor epoxy sealer is a durable coating applied to concrete floors to enhance their appearance and functionality. This sealer is made from a combination of epoxy resin and a hardening agent, creating a strong, adhesive, and resistant surface. Understanding the basics of garage floor epoxy sealer is essential for anyone considering this upgrade for their garage.

- Composition and Properties: Epoxy sealer is composed of two primary components: epoxy resin and a hardening agent. When these two components are mixed, they undergo a chemical reaction that forms a rigid plastic material. This material is highly adhesive, durable, and resistant to chemicals, stains, and impact.

- Types of Epoxy Sealers: There are several types of epoxy sealers available, each designed for specific applications. Water-based epoxy is easy to apply and eco-friendly, making it suitable for DIY projects. Solvent-based epoxy offers higher durability and is often used in commercial settings. Solid epoxy is the most durable but requires professional application due to its complex nature.

- Benefits of Epoxy Sealers: Epoxy sealers provide numerous benefits, including enhanced durability, chemical resistance, and improved aesthetics. They create a seamless surface that is easy to clean and maintain, protecting the underlying concrete from wear and tear. Additionally, epoxy sealers can improve the brightness of a garage by reflecting light.

- Application Process: The application of epoxy sealer involves several steps, including surface preparation, mixing the epoxy components, and applying the sealer. Proper preparation and application are crucial for achieving a smooth, long-lasting finish. Depending on the type of epoxy, drying and curing times can vary, typically ranging from 24 to 72 hours.

- Cost Considerations: The cost of applying an epoxy sealer to a garage floor can vary based on factors such as the size of the garage, the type of epoxy used, and whether professional services are hired. While DIY applications are more affordable, professional installation ensures optimal results, especially for larger or more complex projects.

- Common Uses: While commonly used in garages, epoxy sealers are also suitable for basements, workshops, and commercial spaces. Their durability and resistance to heavy traffic make them ideal for areas that experience significant wear and tear. Understanding the versatility of epoxy sealers can help in selecting the right product for your specific needs.

Benefits of Using Epoxy Sealer for Your Garage Floor

Applying an epoxy sealer to your garage floor can significantly enhance its functionality and appearance. Here are several key benefits of using epoxy sealer:

Enhanced Durability: One of the primary benefits of epoxy sealer is its durability. Epoxy creates a hard, thick coating that withstands heavy traffic, impacts, and abrasions. This makes it ideal for garage floors that endure frequent use and heavy loads, such as vehicles, tools, and equipment.

Chemical Resistance: Epoxy sealers are highly resistant to chemicals, making them suitable for garages where oils, gasoline, and other fluids are present. This resistance prevents staining and damage from spills, ensuring that the garage floor remains in good condition over time.

Improved Aesthetics: Epoxy sealers can transform the appearance of a garage floor. Available in various colors and finishes, including glossy, matte, and metallic, epoxy can enhance the visual appeal of the space. Decorative options, such as flakes and patterns, can also be added to create a customized look.

Easy Maintenance: Maintaining an epoxy-sealed garage floor is straightforward. The seamless surface is easy to clean, as dirt, dust, and debris can be quickly swept away. Spills can be wiped up without staining, and occasional mopping with mild detergent keeps the floor looking pristine.

Moisture Barrier: Epoxy sealer acts as a moisture barrier, protecting the underlying concrete from water damage. This is particularly beneficial in garages prone to dampness or where vehicles bring in water and snow. By preventing moisture infiltration, epoxy extends the lifespan of the concrete.

Increased Property Value: Installing an epoxy floor can increase the value of your property. A well-maintained, aesthetically pleasing garage is an attractive feature for potential buyers. The durability and low maintenance of epoxy floors are also appealing selling points that can enhance the overall value of your home.

Preparation: How to Get Your Garage Floor Ready for Epoxy Sealer

Proper preparation of the garage floor is crucial for the successful application of an epoxy sealer. Here’s a step-by-step guide on how to get your garage floor ready:

Clear the Area: Start by removing all items from the garage. This includes vehicles, tools, and any stored items. Clearing the area ensures that you have unobstructed access to the entire floor and prevents any damage to your belongings during the preparation process.

Clean the Floor: Thoroughly clean the garage floor to remove any dirt, dust, and debris. Use a broom and vacuum to eliminate loose particles, and follow up with a power washer to remove any ingrained dirt and stains. Allow the floor to dry completely before proceeding to the next step.

Repair Cracks and Holes: Inspect the garage floor for any cracks, holes, or imperfections. Use a concrete patching compound to repair these areas. Smooth out the patched areas with a trowel and allow them to cure according to the manufacturer’s instructions. Properly repairing the floor ensures a smooth, even surface for the epoxy application.

Etch the Surface: Etching the concrete is necessary to create a rough surface that promotes the adhesion of the epoxy sealer. Use a concrete etching solution and follow the manufacturer’s instructions for application. After etching, rinse the floor thoroughly with water and allow it to dry completely.

Test for Moisture: Moisture can prevent the epoxy from adhering properly to the concrete. Conduct a moisture test by taping a plastic sheet to the floor and leaving it for 24 hours. If there is condensation under the plastic, the floor may be too damp for epoxy application. Address any moisture issues before proceeding.

Apply a Primer: Applying a primer coat can enhance the adhesion of the epoxy sealer. Choose a primer that is compatible with your epoxy product and apply it according to the manufacturer’s instructions. Allow the primer to dry completely before applying the epoxy sealer. This step ensures a strong bond between the concrete and the epoxy.

Application Process: Step-by-Step Guide to Applying Epoxy Sealer

Applying an epoxy sealer to your garage floor can be a rewarding DIY project. Here’s a step-by-step guide to ensure a successful application:

Mix the Epoxy: Epoxy sealer comes in two parts: the resin and the hardener. Mix these components according to the manufacturer’s instructions, ensuring a thorough blend. Use a clean bucket and a paint stirrer or drill with a mixing attachment for even mixing. Proper mixing is crucial for the epoxy to cure correctly.

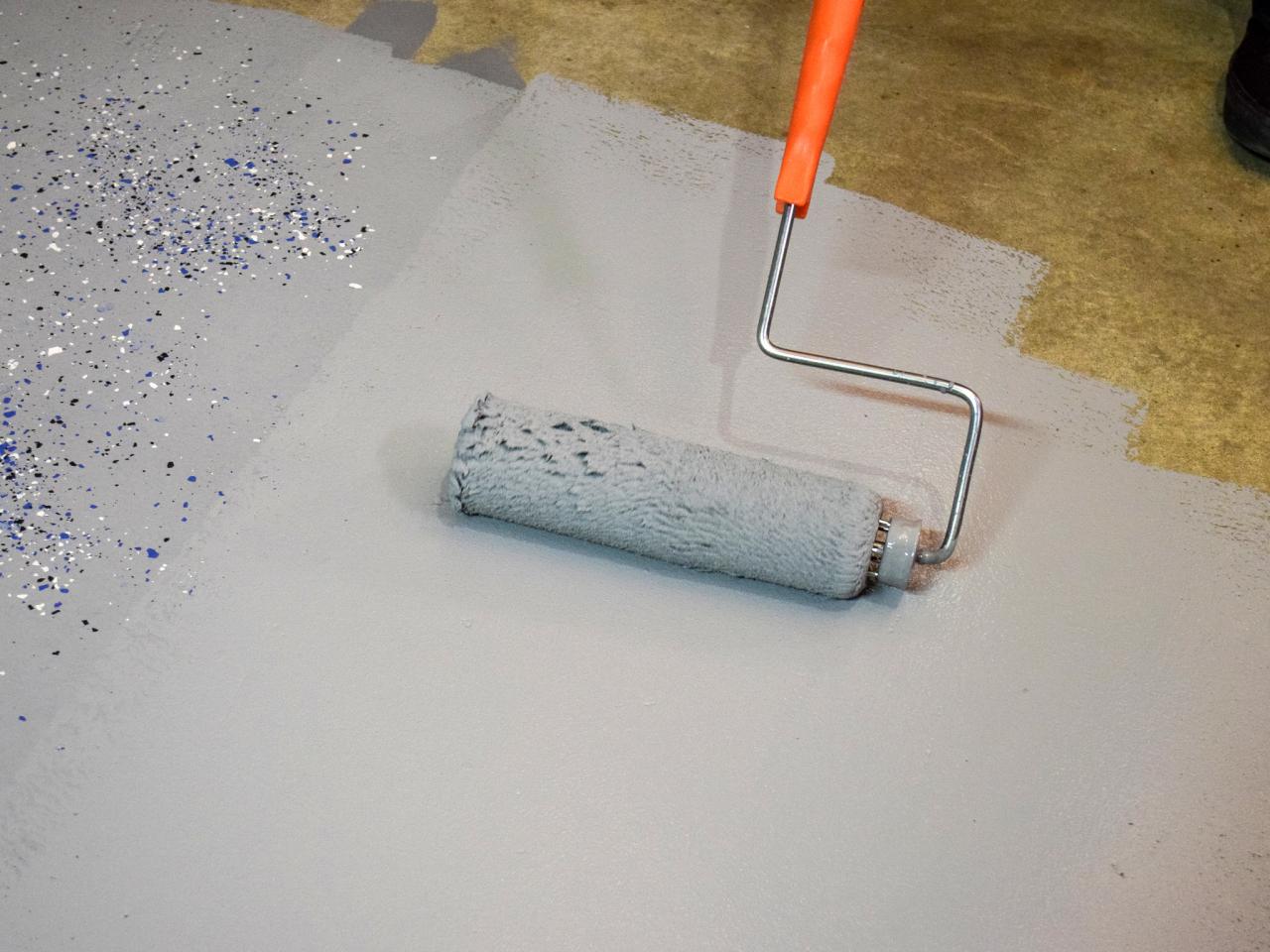

Apply the First Coat: Begin by cutting in the edges of the garage floor with a paintbrush. Then, use a roller to apply the epoxy evenly across the floor. Work in small sections to maintain a wet edge and avoid lap marks. Apply the first coat thinly and evenly, ensuring full coverage. Allow the first coat to dry according to the manufacturer’s recommended drying time.

Add Decorative Elements: If you’re adding decorative flakes or other elements, do so while the first coat is still wet. Sprinkle the flakes evenly across the floor, ensuring a uniform distribution. Decorative elements can enhance the appearance of the epoxy floor and provide additional texture.

Apply the Second Coat: Once the first coat is dry, apply a second coat of epoxy. This coat provides additional durability and a more finished appearance. Use the same method as the first coat, working carefully to ensure even coverage. The second coat should be applied slightly thicker than the first for optimal results.

Allow to Cure: After applying the second coat, allow the epoxy to cure fully. Curing times vary depending on the product and environmental conditions, typically ranging from 24 to 72 hours. Avoid walking on the floor or placing any items in the garage until the epoxy has fully cured to prevent any damage to the surface.

Apply a Topcoat (Optional): For added protection and shine, consider applying a clear topcoat over the cured epoxy. A topcoat can enhance the durability and appearance of the floor, providing a glossy finish that is resistant to UV rays and additional wear. Follow the manufacturer’s instructions for application and curing times.

Maintenance Tips: Keeping Your Epoxy-Sealed Garage Floor Looking New

Maintaining your epoxy-sealed garage floor is essential to preserve its appearance and longevity. Here are some tips to keep your floor looking new:

Regular Cleaning: Sweep or vacuum the floor regularly to remove dust, dirt, and debris. This prevents scratches and keeps the surface looking clean. For deeper cleaning, use a mop with a mild detergent solution. Avoid harsh chemicals that can damage the epoxy finish.

Immediate Spill Cleanup: Epoxy floors are resistant to stains, but it’s still important to clean up spills immediately. Use a soft cloth or paper towel to blot the spill, then clean the area with a mild cleaner and water. Prompt cleanup prevents potential staining and damage to the epoxy surface.

Protect from Heavy Impact: While epoxy is durable, heavy impacts can still cause damage. Use mats or padding under heavy equipment and tools to protect the floor. Avoid dropping heavy objects directly onto the epoxy surface to prevent chips and cracks.

Use Floor Mats: Place floor mats at entry points to reduce the amount of dirt and debris tracked into the garage. Mats can also absorb excess moisture from vehicles, protecting the epoxy surface from water damage. Regularly clean the mats to maintain their effectiveness.

Reapply Topcoat: Over time, the topcoat on your epoxy floor may wear down. Reapplying a clear topcoat every few years can refresh the appearance and provide additional protection. Follow the manufacturer’s instructions for reapplication to ensure a smooth, durable finish.

Monitor for Damage: Regularly inspect your epoxy floor for any signs of damage, such as chips, cracks, or wear spots. Addressing these issues promptly can prevent further deterioration. Small repairs can often be done using epoxy repair kits, ensuring the floor remains in good condition.

Common Mistakes to Avoid When Using Garage Floor Epoxy Sealer

Applying epoxy sealer to a garage floor can be a straightforward process, but certain mistakes can compromise the results. Here are common mistakes to avoid:

Inadequate Surface Preparation: Skipping or rushing through surface preparation can lead to poor adhesion and peeling. Ensure the concrete is clean, dry, and free of any contaminants. Properly repair any cracks and etch the surface to promote better bonding of the epoxy sealer.

Incorrect Mixing Ratios: Epoxy sealer requires precise mixing of resin and hardener. Incorrect ratios can result in improper curing and a weak finish. Follow the manufacturer’s instructions carefully and mix the components thoroughly to ensure a uniform consistency.

Poor Timing: Temperature and humidity play crucial roles in the application process. Applying epoxy in extreme temperatures or high humidity can affect curing times and finish quality. Ensure the environment is within the recommended range for the epoxy product you’re using.

Applying Too Thick or Too Thin: Applying the epoxy sealer too thickly can cause it to bubble and not cure properly while applying it too thinly can result in inadequate coverage and durability. Follow the manufacturer’s guidelines for the correct thickness and use a consistent application technique.

Ignoring Drying and Curing Times: Rushing the drying and curing process can lead to a weak and easily damaged finish. Allow each coat to dry fully before applying additional layers and let the final coat cure completely before using the garage. Patience ensures a stronger, more durable finish.

Lack of Protective Gear: Epoxy products contain chemicals that can be harmful if inhaled or come into contact with skin. Always wear appropriate protective gear, including gloves, goggles, and a respirator. Proper ventilation in the work area is also crucial to avoid exposure to fumes.

Garage Floor Coating – Flores Decorative Concrete – Epoxy Paint

Garage Flooring Ideas For Men – Paint, Tiles And Epoxy Coatings

Best Epoxy Floor Paint – Complete Guide for Epoxy Painting

Epoxy Garage Floor Coatings CT u0026 NY Shoreline Painting

Related Posts: