Hardwood floors are not difficult adequate to sweep or dust and also mopping, though it needs cleaning solutions created for hardwood floors. You also don't have to contend with that micro bevel groove between each board that is likely to fill up with crumbs as well as dust. Wood floors have the proper, warm and beautiful look that is ideal for all kinds of rooms. Which includes changes in surface moisture, subfloor moisture, and humidity.

Images about Glue For Floating Engineered Wood Flooring

Glue For Floating Engineered Wood Flooring

You likewise have to ensure that you wash your sub-floor totally to eliminate any dirt and small particles which could cause issue in case you come to set the wood flooring. Many people don't know that wood flooring has some unique characteristics which make it not the perfect method for everyone. They're also eco-friendly, inexpensive and the best part is, there is a good deal of variety available.

How to Install Floating Hardwood Flooring – The Glue-Seam Method

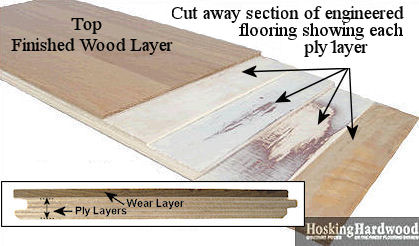

Due to our precise sanding throughout the lamination procedure for the engineered product and after, parts are more constant in position, far more consistent in texture, fit collectively tighter, with no waste, cracks and gaps already filled, and hardly any sanding necessary after install until you should do a light display or buff. You can still have that appealing hardwood warmth and appeal with an engineered floor.

Floating Wood Floor: Install One in 8 Steps – This Old House

/cdn.vox-cdn.com/uploads/chorus_asset/file/19493650/0405_flooring_illo.jpg)

Glue Down or Floating Floor: Which Flooring Option is Better for

Floating vs. Glue-Down Engineered Hardwood

Floating Wood Floor: Install One in 8 Steps – This Old House

Floating Vs. Glue-Down Wood Flooring [Pros u0026 Cons]

Floating Floors Pros and Cons

All About Floating Wood Floors

Floating Floor vs. Nail Down Slaughterbeck Floors, Inc.

Can a Floating Floor be Glued? – Home Inspection Insider

Floating Vs. Glue-Down Wood Flooring [Pros u0026 Cons]

Glueless Click Installation for Floating Hardwood Floors

All About Floating Wood Floors

Related Posts:

- Grey Wood Flooring Bathroom

- Rustic White Wood Flooring

- Wide Plank Pine Wood Flooring

- Blue Grey Wood Flooring

- Light Wood Flooring Ideas

- Distressed Wood Flooring

- Acacia Wood Flooring

- Wood Flooring Design

- Kitchen Engineered Wood Flooring

- Wood Floor Care Guide

What is Glue for Floating Engineered Wood Flooring?

Glue for floating engineered wood flooring is a type of adhesive specifically designed for use when installing engineered wood floors. It is used to secure the planks to each other, creating a solid, stable base. Generally, it is applied to the tongues and grooves of each plank and allowed to dry before the planks are joined together. This ensures that your floor will stay in place without any shifting or squeaking. The glue also helps to reduce sound transmission between rooms, making it ideal for multi-level homes.

Types of Glue for Floating Engineered Wood Flooring

There are two main types of glue used for floating engineered wood floors: water-based and solvent-based adhesives. Water-based adhesives are generally easier to use, as they are less toxic and clean up more easily with just soap and water. They also offer better initial grab than solvent-based adhesives, helping to ensure a secure bond between the planks. Solvent-based adhesives are more powerful, providing a stronger bond with better adhesion and longer lasting results. As such, they are often used in commercial settings where more durability is needed.

Advantages of Using Glue for Floating Engineered Wood Flooring

One of the biggest advantages of using glue for floating engineered wood flooring is how quickly it can be installed. Since you don’t have to wait for the glue to dry before laying down the next plank, you can complete the job in a fraction of the time it would take with traditional installation methods. In addition, glue helps to reduce noise transmission between rooms, making it an ideal choice for multi-level homes or businesses. Finally, glue provides a more secure bond than other installation methods, ensuring that your floor will stay in place without shifting or squeaking over time.

How to Install Glue for Floating Engineered Wood Flooring

The process of installing glue for floating engineered wood flooring is relatively simple. First, make sure that the subfloor is level and free from debris. Then, spread a thin layer of adhesive onto the tongue and groove of each plank, taking care not to get any on the visible surface of the flooring. Allow the adhesive to set until it becomes tacky before laying down each plank and pressing it firmly into place. Once all the planks are laid down, allow the adhesive to completely dry before walking on it or adding furniture or rugs.

FAQs about Glue for Floating Engineered Wood Flooring

Q: Is glue necessary when installing engineered wood floors?

A: While glue isn’t absolutely necessary when installing engineered wood floors, it can help ensure that your floor stays in place without shifting or squeaking over time. Additionally, it helps reduce sound transmission between rooms, making it ideal for multi-level homes or businesses.

Q: How long does glue take to dry?

A: Generally, most glues will take about 24 hours to fully dry and cure. However, this can vary depending on the type of adhesive you use as well as environmental factors such as humidity and temperature. It’s always best to follow the manufacturer’s instructions when determining how long you should wait before walking on your flooring or adding furniture or rugs.

Q: Can I use regular wood glue when installing my engineered wood floors?

A: No, regular wood glue is not suitable for use when installing engineered wood floors. Instead, you should use a specialized adhesive specifically designed for use with floating engineered wood flooring. This type of glue offers better initial grab and stronger adhesion than regular wood glue, helping to ensure a secure bond between the planks.

:no_upscale()/cdn.vox-cdn.com/uploads/chorus_asset/file/19493784/howto_tilefloor_04.jpg)

/what-is-a-floating-floor-1821740-hero-00e6b7fe102e4fafa8ba3f926944bcb7.jpg)