What is Roll On Epoxy Flooring?

Roll On Epoxy Flooring is a type of flooring system that is applied using a roll-on method. It is a popular choice for both residential and commercial spaces due to its durability and aesthetic appeal. This type of flooring is made from a combination of epoxy resin and hardeners, which create a strong and seamless surface when applied correctly.

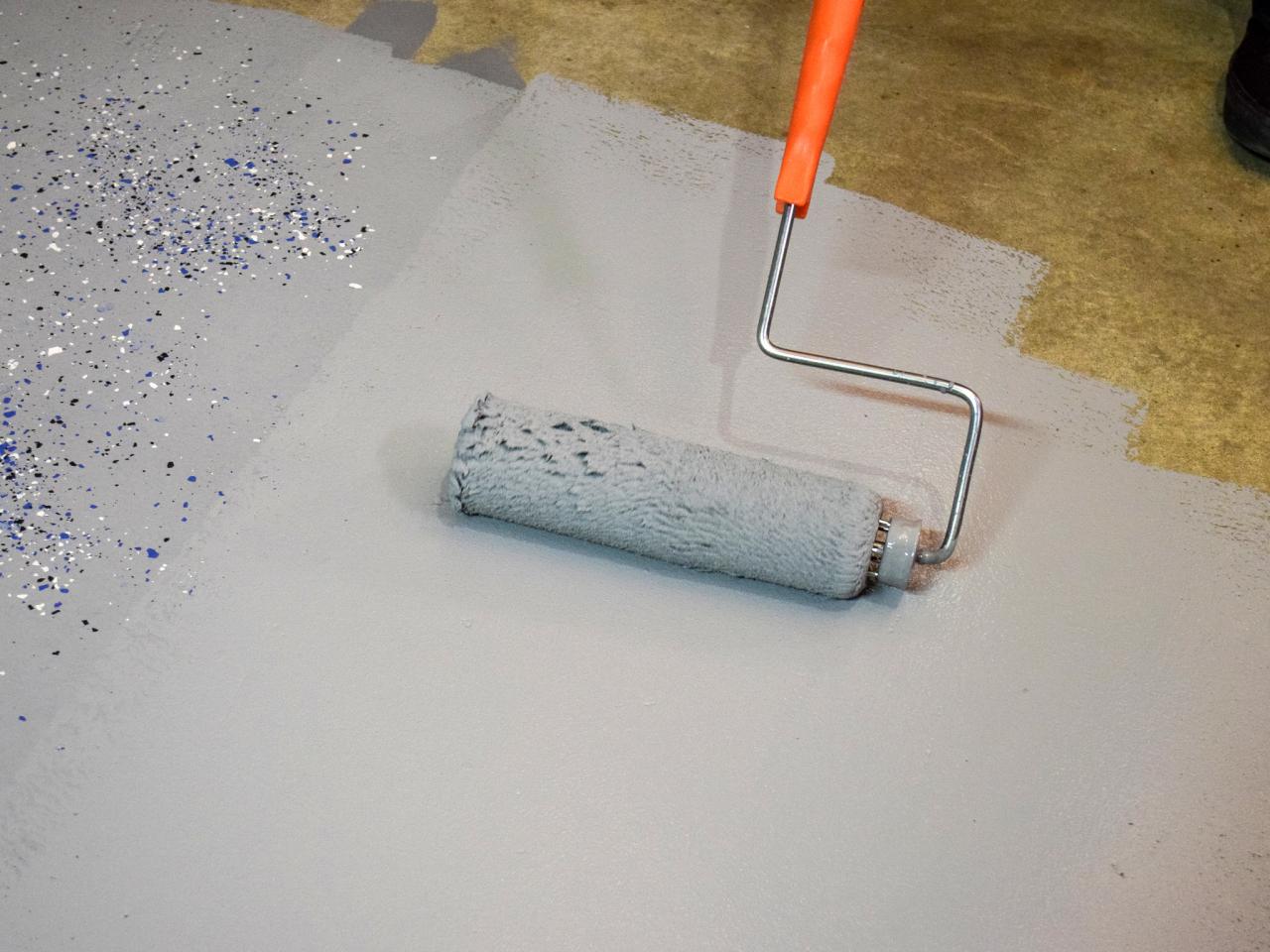

The application process for Roll On Epoxy Flooring involves first preparing the surface by cleaning and repairing any cracks or imperfections. Once the surface is ready, the epoxy resin is mixed with the hardener according to the manufacturer’s instructions. The mixture is then poured onto the floor and spread evenly using a roller. The epoxy is self-leveling, which means it will naturally spread to create a smooth and even surface.

One of the main benefits of Roll On Epoxy Flooring is its durability. This type of flooring is highly resistant to wear and tear, making it ideal for high-traffic areas. It is also resistant to chemicals, stains, and moisture, making it a suitable choice for spaces such as garages, warehouses, and industrial facilities.

In addition to its durability, Roll On Epoxy Flooring also offers a wide range of design options. The epoxy resin can be tinted or mixed with various pigments to create custom colors and patterns. This allows for endless possibilities in terms of design, making it a versatile flooring option for any space.

Roll On Epoxy Flooring is also relatively easy to maintain. The smooth and seamless surface makes it easy to clean, as dirt and debris can be easily swept or mopped away. Additionally, the epoxy coating helps to protect the underlying concrete or substrate from damage, extending its lifespan.

Roll On Epoxy Flooring is a practical and stylish choice for any space. Its durability, design options, and ease of maintenance make it a popular flooring solution for both residential and commercial applications. Whether it is used in a garage, kitchen, or showroom, Roll On Epoxy Flooring provides a long-lasting and attractive surface.

Benefits of Roll On Epoxy Flooring

Cost-effective: Roll-on epoxy flooring is a cost-effective solution compared to other flooring options. It requires minimal maintenance and has a longer lifespan, reducing the need for frequent repairs or replacements. This makes it a cost-effective choice for both residential and commercial spaces.

Durability: Epoxy flooring is known for its exceptional durability. It can withstand heavy foot traffic, impact, and abrasion without losing its quality or appearance. Roll-on epoxy flooring provides a smooth and seamless surface, making it resistant to cracks, chips, and stains. It is an ideal choice for high-traffic areas such as garages, warehouses, and industrial facilities.

Easy to clean and maintain: Roll on epoxy flooring is incredibly easy to clean and maintain. Its smooth and seamless surface prevents dirt, dust, and stains from penetrating the floor, allowing for effortless cleaning. Regular sweeping and occasional mopping are all that is needed to keep the floor looking pristine. Additionally, the non-porous nature of epoxy flooring makes it resistant to chemicals and spills, further simplifying the cleaning process.

Versatility: Roll-on epoxy flooring offers endless design possibilities, allowing you to customize the look of your space. It is available in a wide range of colors, patterns, and finishes, enabling you to create a unique and visually appealing flooring solution. Whether you prefer a glossy finish for a modern aesthetic or a matte finish for a more subdued look, roll on epoxy flooring can be tailored to match your specific style and requirements.

Safety: Roll-on epoxy flooring provides a safe environment for both residential and commercial spaces. It has excellent slip resistance, even when wet, reducing the risk of accidents and injuries. Additionally, epoxy flooring is resistant to fire, chemicals, and bacteria growth, making it a safe choice for areas that require a high level of hygiene, such as hospitals, laboratories, and food processing facilities.

Quick installation: Roll on epoxy flooring can be installed quickly and efficiently, minimizing downtime for your space. The process involves applying the epoxy coating directly onto the prepared floor, allowing for a seamless and hassle-free installation. This is particularly beneficial for commercial spaces that cannot afford extensive closures or disruptions to their operations.

How to Apply Roll-On Epoxy Flooring

Roll On Epoxy Flooring is a popular choice for many homeowners and businesses due to its durability and easy application process. If you are considering installing roll on epoxy flooring in your space, follow these steps for a successful application:

- Prepare the Surface: Before applying roll on epoxy flooring, it is crucial to prepare the surface properly. Remove any existing flooring, clean the area thoroughly, and repair any cracks or imperfections. Ensure that the surface is dry and free of dust, dirt, and grease.

- Choose the Right Epoxy: There are various types of epoxy available in the market. Select the one that suits your needs and the requirements of your space. Consider factors such as the level of foot traffic, chemical resistance, and desired finish.

- Mix the Epoxy: Follow the manufacturer’s instructions to mix the epoxy resin and hardener. Use a drill with a mixing attachment to ensure a thorough and consistent mix. Be sure to mix only the amount of epoxy that you can apply within the pot life mentioned by the manufacturer.

- Apply a Primer: Applying a primer is essential to ensure proper adhesion of the epoxy to the surface. Use a roller or brush to apply the primer evenly over the entire area. Allow the primer to dry as per the manufacturer’s instructions.

- Apply the Epoxy: Once the primer is dry, it’s time to apply the roll-on epoxy. Pour the epoxy mixture onto the floor and use a roller to spread it evenly. Work in small sections, starting from the corner farthest from the exit, and roll in parallel lines to achieve a consistent thickness.

- Add Decorative Elements (Optional): If you desire a decorative finish, you can add decorative elements such as flakes, metallic pigments, or quartz crystals to the wet epoxy. Sprinkle them evenly over the surface and use a roller to press them into the epoxy.

- Allow Curing: After applying the epoxy, give it sufficient time to cure. Follow the manufacturer’s instructions for the recommended curing time. Avoid walking on the newly coated floor until it is completely cured.

- Apply a Topcoat (Optional): To enhance the durability and longevity of your roll on epoxy flooring, consider applying a topcoat. This will provide an extra layer of protection against wear, stains, and chemicals. Follow the manufacturer’s instructions to apply the topcoat evenly.

Maintaining and Cleaning Roll On Epoxy Flooring

Roll on epoxy flooring is a popular choice for its durability and easy maintenance. To keep your roll on epoxy flooring looking its best, it is important to follow proper cleaning and maintenance practices. Here are some tips to help you maintain and clean your roll-on epoxy flooring:

- Regular sweeping and dusting: It is important to regularly sweep or dust your roll on epoxy flooring to remove loose dirt, dust, and debris. This can be done using a soft-bristle broom or a dust mop. Avoid using abrasive tools or materials that could scratch or damage the epoxy surface.

- Spill cleanup: Promptly clean up any spills on your roll on epoxy flooring to prevent staining or damage. Use a damp cloth or mop to wipe up the spill, and then dry the area thoroughly. Avoid using harsh chemicals or abrasive cleaners, as they can strip away the epoxy coating.

- Routine mopping: Periodically, you may need to mop your roll on epoxy flooring to remove dirt and grime. Use a mild, non-abrasive cleaner and warm water to clean the floor. Avoid using vinegar or acidic cleaners, as they can dull the epoxy surface.

- Stain removal: If your roll-on epoxy flooring becomes stained, it is important to address the stain as soon as possible. Mild stains can often be removed using a soft cloth or sponge and a mild detergent. For more stubborn stains, you may need to use a specialized epoxy stain remover. Always follow the manufacturer’s instructions when using any stain removal product.

- Avoiding heavy objects and dragging: While roll-on epoxy flooring is known for its durability, it is still important to take precautions to prevent damage. Avoid dragging heavy objects or furniture across the floor, as this can scratch or chip the epoxy surface. Instead, use furniture pads or lift heavy objects when moving them.

- Regular maintenance: In addition to regular cleaning, it is important to perform routine maintenance on your roll on epoxy flooring. This may include inspecting for any areas of damage or wear and addressing them promptly. If you notice any chips or cracks in the epoxy coating, it is important to repair them to prevent further damage.

Roll On Rock® Epoxy Flake Kits GarageCoatings.com

Roll On Rock® Epoxy Flake Kits GarageCoatings.com

Roll On Rock® Epoxy Flake Kits GarageCoatings.com

We Review the Roll On Rock® Epoxy Garage Flooring Kit All Garage

Roll On Rock® Epoxy Flake Kits GarageCoatings.com

How to Resurface a Garage Floor HGTV

Roll On Rock® Epoxy Flake Kits GarageCoatings.com

Roll On Rock Flooring Installed in Glendale, Arizona Rock floor

Related Posts: