Epoxy flooring supplies a total strategy to these problems. Epoxy is made up of hardeners and resins. It has high resistance to abrasion as well as chemicals for instance alkalis, fuel, greases, thawing salts, and solvents. For optimum epoxy drying, air temperature should be between sixty as well as 90 degrees with the minimum concrete temperature of 55 degrees F. A blank concrete floor isn't very appealing or even professional looking.

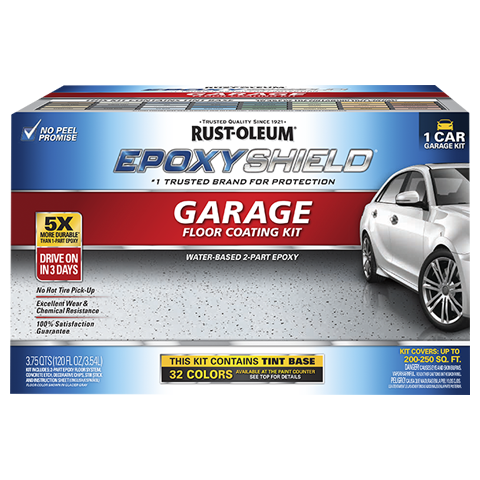

Images about Rustoleum Epoxy Floor Coating Kit

Rustoleum Epoxy Floor Coating Kit

They come in many different colors so matching isn't a problem and you will get the same very long lasting durability that commercial industries get. You will find a lot of distinct flooring companies specializing in the apps of epoxy resins. Epoxy flooring coatings are high-performing and versatile because of the inherent chemical attributes of epoxy. Odds are that the concrete is damaged as well as tarnished.

Rust-Oleum EpoxyShield 2-part Gray Gloss Concrete and Garage Floor

Epoxy flooring isn't cheap and the price of a floor depends on the size of the surface to be covered, naturally. Epoxy is long-lasting adequate to resist a lot of stains and still keep a nice looking floor. In addition to choosing a floor color, buyers also have an opportunity to improve their floor's uniqueness with anti-slip flecks. Epoxy flooring is usually utilized in an industrial setting.

Rust-Oleum EpoxyShield 90 oz. Gray Epoxy 1 Car Garage Floor Kit 365184

EPOXYSHIELD® Garage Floor Coating Tint Base Kit Product Page

Rust-Oleum 261845 EpoxyShield Garage Floor Coating , 2 gal, Gray

Rust-Oleum EpoxyShield 240 oz. Gray High-Gloss 2.5-Car Garage

EpoxyShield Premium Clear Garage Floor Coating Rust-Oleum

Tan, Rust-Oleum EpoxyShield 2.5 Car Garage Floor Gloss Kit, 240 Oz

Rust-Oleum Epoxy Shield Garage Floor Paint Coating Kit

Rust-Oleum 299743 RockSolid Metallic Garage Floor Coating Kit, 80 fl oz, Gunmetal

Polycuramine® Garage Floor Coating Kit

Rust Oleum Epoxy Shield Protect Gray Garage Floor Coating Kit High Gloss 2.5 Car eBay

Polycuramine® Garage Floor Coating Kit

How to Use Rust-Oleum® Epoxyshield® Garage Floor Coating Kit to Transform Your Floor

Related Posts:

- High Gloss Epoxy Floor

- Decorative Epoxy Flooring

- Epoxy Floor Garage DIY

- DIY Epoxy Kitchen Floor

- Best Epoxy Floor Paint For Garage

- DIY Epoxy Garage Floor

- Metallic Epoxy Floor

- DIY Garage Epoxy Floor

- Indoor Epoxy Flooring

- Epoxy Resin Shower Floor

Introduction to Rustoleum Epoxy Floor Coating Kit

Rustoleum epoxy floor coating kit is a great way to give your home or business a new look and feel. This product is easy to apply and provides durability, protection, and a beautiful finish. The kit comes with everything you need to get the job done, including epoxy resin, hardener, mixing cups and stirrers, and an applicator tool. With just a few hours of work, you can have a brand-new looking floor in no time.

Advantages of Rustoleum Epoxy Floor Coating Kit

Rustoleum epoxy floor coating kit offers many advantages over other types of flooring. It is resistant to stains, chemicals, and wear and tear, making it an excellent choice for high-traffic areas like kitchens and bathrooms. The finish is durable and relatively easy to clean, making it ideal for households with children or pets. In addition, the kit comes with easy-to-follow instructions that make it simple for homeowners to install.

Application Process of Rustoleum Epoxy Floor Coating Kit

Applying the Rustoleum epoxy floor coating kit is relatively simple. First, the area must be properly prepared by cleaning it thoroughly and removing any existing sealers or waxes. Once the floor is ready, the epoxy resin is mixed with the hardener in the provided cups according to the instructions. The mixed solution is then poured onto the floor using the applicator tool and spread evenly with a squeegee to ensure full coverage. After allowing enough time for the epoxy to set and cure, a second layer may be applied if desired.

Durability of Rustoleum Epoxy Floor Coating Kit

One of the best features of Rustoleum epoxy floor coating kit is its durability. The epoxy resin creates an extremely hard surface that resists scratches and scuffs, making it perfect for high-traffic areas like kitchens and bathrooms. In addition, it is resistant to stains from oils, grease, and other liquids, making it ideal for commercial applications such as restaurants and supermarkets. The finish is also highly resistant to fading from sunlight or other forms of UV radiation, ensuring that your floor will look great for years to come.

Maintenance of Rustoleum Epoxy Floor Coating Kit

Maintaining your Rustoleum epoxy floor coating kit is fairly straightforward. To keep it looking its best, simply mop the surface regularly with a mild detergent or cleaner designed for epoxy floors. If spills occur, they should be wiped up quickly with a damp cloth before they can cause permanent damage to the finish. Additionally, furniture should be placed on felt pads or glides in order to prevent scratching or scuffing on the surface.

FAQs Related to Rustoleum Epoxy Floor Coating Kit

Q: Does Rustoleum epoxy floor coating kit require special tools or skills?

A: No special tools are required for applying Rustoleum epoxy floor coating kit; however, some basic skills may be needed depending on the size and shape of your space. Additionally, some basic safety precautions should be taken when handling the resin and hardener components of the kit in order to avoid injury or damage.

Q: How long does it take for Rustoleum epoxy floor coating kit to dry?

A: The amount of time needed for Rustoleum epoxy floor coating kit to dry will depend on several factors such as temperature, humidity levels, and air circulation in the space where it is applied. Typically, however, most applications will require at least 24 hours before any foot traffic is allowed on them.

Q: Is Rustoleum epoxy floor coating kit suitable for outdoor use?

A: Yes, Rustoleum epoxy floor coating kit can be used outdoors; however, it should only be applied over concrete surfaces that are not exposed to direct sunlight or extreme temperatures. Additionally, additional coats may need to be applied in order to provide adequate protection against UV rays and other elements found outdoors.