The Importance of Sill Gaskets in Basement Construction

Sill gaskets may seem like a small detail in the grand scheme of basement construction, but their significance cannot be overstated. These humble yet crucial components play a vital role in ensuring the longevity, stability, and overall health of your basement structure. Let’s find out why sill gaskets are so essential in basement construction.

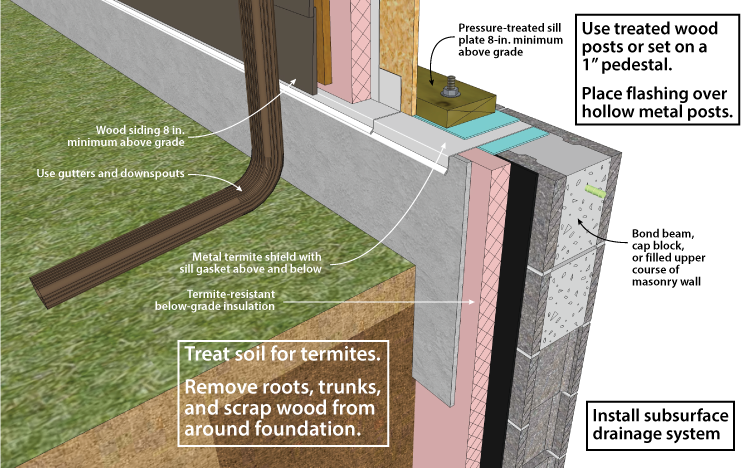

- Moisture Prevention: Basements are particularly susceptible to moisture infiltration, which can lead to a host of problems such as mold growth, rot, and structural damage. Sill gaskets create a barrier between the foundation and the framing above, preventing moisture from seeping into the basement through the joint.

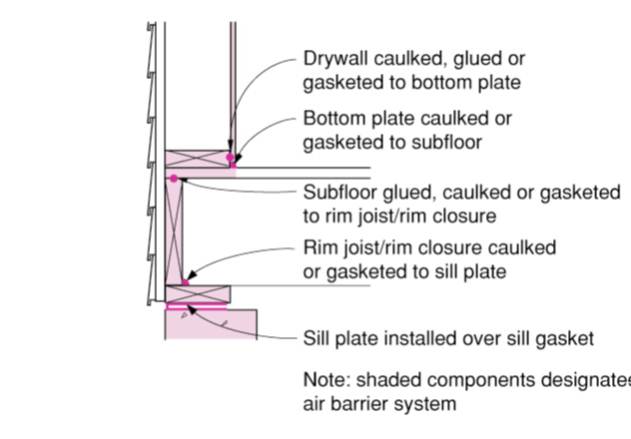

- Energy Efficiency: Properly installed sill gaskets help create a more airtight seal between the foundation and the framing, reducing the infiltration of outside air. This not only helps maintain a more comfortable indoor environment but also improves energy efficiency by reducing heating and cooling costs.

- Pest Control: In addition to moisture, basements can also attract pests such as termites and ants, which can cause extensive damage to the structure over time. Sill gaskets act as a deterrent to pests, making it more difficult for them to gain entry into your home through the foundation.

- Structural Integrity: Sill gaskets provide a cushioning effect between the foundation and the framing, helping to absorb and distribute the load more evenly. This can help prevent the settling and shifting of the structure over time, ensuring its long-term stability and integrity.

- Building Code Compliance: Many building codes now require the use of sill gaskets in basement construction to meet energy efficiency and moisture control standards. By incorporating sill gaskets into your basement build, you can ensure compliance with these regulations and avoid potential issues during inspections.

Types of Sill Gaskets: Which One Is Right for Your Basement Floor?

When it comes to choosing the right sill gasket for your basement floor, it’s essential to consider factors such as material, thickness, and compatibility with your specific construction needs. With various options available on the market, selecting the most suitable type of sill gasket can make a significant difference in the performance and longevity of your basement structure. Let’s discuss some of the most common types of sill gaskets and their respective benefits.

Foam Sill Gaskets: Foam sill gaskets are among the most popular choices due to their affordability and ease of installation. Typically made from closed-cell polyethylene foam, these gaskets provide excellent moisture resistance and thermal insulation properties. They are available in various thicknesses to accommodate different foundation types and can be easily cut to size for a custom fit.

Rubber Sill Gaskets: Rubber sill gaskets offer superior durability and resilience compared to foam gaskets. Made from synthetic rubber compounds such as EPDM or neoprene, these gaskets provide an effective barrier against moisture, air infiltration, and pests. They are also highly resistant to compression, ensuring long-lasting performance even under heavy loads.

Bituminous Sill Gaskets: Bituminous sill gaskets are typically made from asphalt-saturated felt or rubberized asphalt compounds. These gaskets provide excellent waterproofing properties and are particularly well-suited for basements with high moisture levels or in areas prone to flooding. However, they may be more challenging to install compared to foam or rubber gaskets and may require professional assistance.

Composite Sill Gaskets: Composite sill gaskets combine the benefits of multiple materials, such as foam and rubber, to provide enhanced performance and durability. These gaskets may feature a foam core for insulation and a rubber or bituminous outer layer for waterproofing and pest resistance. While composite gaskets may be more expensive than single-material options, they offer superior overall protection and longevity.

Self-Adhesive Sill Gaskets: Self-adhesive sill gaskets come with an adhesive backing that allows for quick and easy installation without the need for additional fasteners or adhesives. These gaskets are ideal for DIY enthusiasts or contractors looking to streamline the installation process. However, it’s essential to ensure proper surface preparation to achieve a secure and long-lasting bond.

Installation Tips and Best Practices

Proper installation of sill gaskets is crucial to maximize their effectiveness in protecting your basement floor from moisture, air infiltration, and pests. Whether you’re a seasoned contractor or a DIY enthusiast, following these tips and best practices can help ensure a successful installation process and long-lasting performance of your sill gaskets.

Clean and Prepare the Foundation: Before installing sill gaskets, it’s essential to thoroughly clean and prepare the foundation surface to ensure proper adhesion. Remove any dirt, debris, or existing sealants from the foundation using a wire brush or scraper. Ensure that the surface is dry and free of moisture before proceeding with the installation.

Cut Sill Gaskets to Size: Measure the length and width of the foundation wall where the sill gaskets will be installed and cut the gaskets to size accordingly. Use a sharp utility knife or scissors to ensure clean, precise cuts. Avoid stretching or compressing the gaskets during cutting to maintain their integrity and effectiveness.

Apply Adhesive (If Necessary): If you’re using self-adhesive sill gaskets, simply peel off the backing and press the gaskets onto the clean, dry foundation surface. If your gaskets do not have adhesive backing, apply a bead of compatible construction adhesive along the length of the foundation wall before installing the gaskets.

Overlap Corners and Joints: When installing sill gaskets around corners or at joints, ensure that the gaskets overlap each other to create a continuous seal. Use a utility knife to miter the corners of the gaskets at a 45-degree angle to ensure a snug fit and prevent gaps or gaps in the seal.

Secure Gaskets with Fasteners: For added stability and security, consider securing the sill gaskets in place with appropriate fasteners such as nails, screws, or staples. Space the fasteners evenly along the length of the gaskets, ensuring that they penetrate the foundation wall sufficiently to provide a secure hold.

Inspect and Seal Any Gaps: Once the sill gaskets are installed, carefully inspect the entire perimeter for any gaps, tears, or inconsistencies in the seal. Use additional sealant or waterproofing compound to fill any gaps or voids and ensure a complete and continuous barrier against moisture and pests.

Common Problems and Solutions

While sill gaskets are essential components in basement construction, they can sometimes encounter issues that compromise their effectiveness and performance. Understanding common problems and their respective solutions can help you address issues promptly and ensure the continued protection and integrity of your basement structure. Below are some of the most common problems encountered when using sill gaskets in basement construction and how to resolve them.

Poor Adhesion: One common issue with sill gaskets is poor adhesion to the foundation wall, which can result in gaps or separation over time. This can occur due to inadequate surface preparation, incompatible adhesive, or improper installation techniques. To address this issue, ensure that the foundation surface is clean, dry, and free of any debris or contaminants before installing the gaskets. Use a compatible construction adhesive and follow proper installation procedures to ensure a secure and long-lasting bond.

Compression or Damage: Sill gaskets can become compressed or damaged during installation or as a result of settling or shifting of the structure over time. This can compromise their ability to provide an effective seal and protection against moisture and pests. To prevent compression or damage, handle the gaskets with care during installation and avoid over-tightening fasteners or applying excessive pressure. Additionally, consider using more durable gasket materials such as rubber or composite for enhanced resilience and longevity.

Inadequate Coverage: Insufficient coverage of sill gaskets along the foundation wall can leave gaps or unprotected areas, allowing moisture and pests to infiltrate the basement. This can occur due to improper measuring, cutting, or installation techniques. To ensure adequate coverage, carefully measure and cut the gaskets to size, overlapping them at corners and joints to create a continuous seal. Use additional gasket material or sealant to fill any gaps or voids and ensure complete coverage along the entire perimeter of the basement floor.

Moisture Seepage: Despite the presence of sill gaskets, moisture seepage can still occur if the gaskets are not properly installed or if there are other sources of water infiltration in the basement. Common causes of moisture seepage include foundation cracks, improper grading, or inadequate drainage systems. To address this issue, inspect the foundation for any cracks or leaks and repair them promptly. Ensure that the surrounding landscape is graded away from the foundation to prevent water from pooling around the basement walls. Consider installing a sump pump or interior drainage system to manage excess moisture and prevent seepage into the basement.

Pest Infestation: Sill gaskets are designed to deter pests such as termites and ants from entering the basement through the foundation. However, if the gaskets are damaged or improperly installed, pests can still find their way into the structure. To prevent pest infestation, inspect the sill gaskets regularly for any signs of damage or deterioration and repair or replace them as needed. Additionally, seal any cracks or openings in the foundation walls and ensure that exterior landscaping is kept well-maintained to discourage pests from nesting near the basement.

The Long-Term Benefits of Using Sill Gaskets for Your Basement Floor

Investing in sill gaskets for your basement floor offers a range of long-term benefits that extend far beyond simple moisture protection. From improved energy efficiency to enhanced structural integrity, sill gaskets play a crucial role in ensuring the durability, comfort, and longevity of your basement space. Let’s discuss some of the key long-term benefits of using sill gaskets for your basement floor.

Moisture Control: One of the primary benefits of sill gaskets is their ability to create a barrier against moisture infiltration from the foundation into the basement. By preventing moisture from seeping into the basement space, sill gaskets help mitigate the risk of mold growth, rot, and structural damage over time. This not only helps preserve the integrity of the basement floor and walls but also maintains a healthier indoor environment for occupants.

Energy Efficiency: Properly installed sill gaskets help create a more airtight seal between the foundation and the framing, reducing the infiltration of outside air into the basement space. This can lead to significant energy savings by minimizing heat loss in the winter and heat gain in the summer. By improving the overall energy efficiency of the basement, sill gaskets help reduce heating and cooling costs and contribute to a more comfortable living environment year-round.

Pest Prevention: Sill gaskets act as a deterrent to pests such as termites, ants, and rodents, helping prevent them from gaining entry into the basement through the foundation. By creating a physical barrier that pests cannot easily penetrate, sill gaskets help protect the structural integrity of the basement and minimize the risk of costly damage from pest infestation over time. This can save homeowners time and money on pest control measures and repairs, ensuring the long-term value of their property.

Structural Stability: By providing a cushioning effect between the foundation and the framing above, sill gaskets help distribute the load more evenly and reduce the risk of settling or shifting of the structure over time. This helps maintain the structural integrity and stability of the basement floor and walls, ensuring that they remain level, plumb, and free from cracks or damage. By minimizing the effects of settling and shifting, sill gaskets help preserve the long-term value and usability of the basement space for years to come.

Code Compliance: Many building codes now require the use of sill gaskets in basement construction to meet energy efficiency and moisture control standards. By incorporating sill gaskets into your basement build, you can ensure compliance with these regulations and avoid potential issues during inspections. This not only provides peace of mind for homeowners but also helps maintain the resale value of the property by ensuring that it meets current building code requirements.

Air Sealing Sill Plates Building America Solution Center

Insulating Basement, Need Some Advice Puhleaze! Basement

Air Sealing Sill Plates Building America Solution Center

XPS or PVC under base plate – GreenBuildingAdvisor

Air Sealing Sill Plates Building America Solution Center

BASEMENT BUILDOUT : FRAME OF REFERENCE u2013 the MAD creative

DOE Building Foundations Section 2-2

Sill Sealer Home insulation, Basement insulation, Construction diy

DOE Building Foundations Section 2-1 Recommendations

Related Posts:

- Basement Floor Color Ideas

- Rubber Flooring For Basement

- How To Clear A Basement Floor Drain

- Basement Floor Covering Ideas

- Acid Wash Basement Floor

- Best Flooring For Concrete Basement Floor

- Insulation Under Basement Floor

- Stone Basement Floor

- Basement Floor Leveling Options

- Basement Flooring Options Inexpensive