Introducing Thermal Breaks in Basement Flooring

When it comes to basement flooring, many homeowners overlook the importance of incorporating thermal breaks. However, understanding and implementing thermal breaks can make a significant difference in the comfort and energy efficiency of your home. So, what exactly are thermal breaks, and why are they essential for basement flooring?

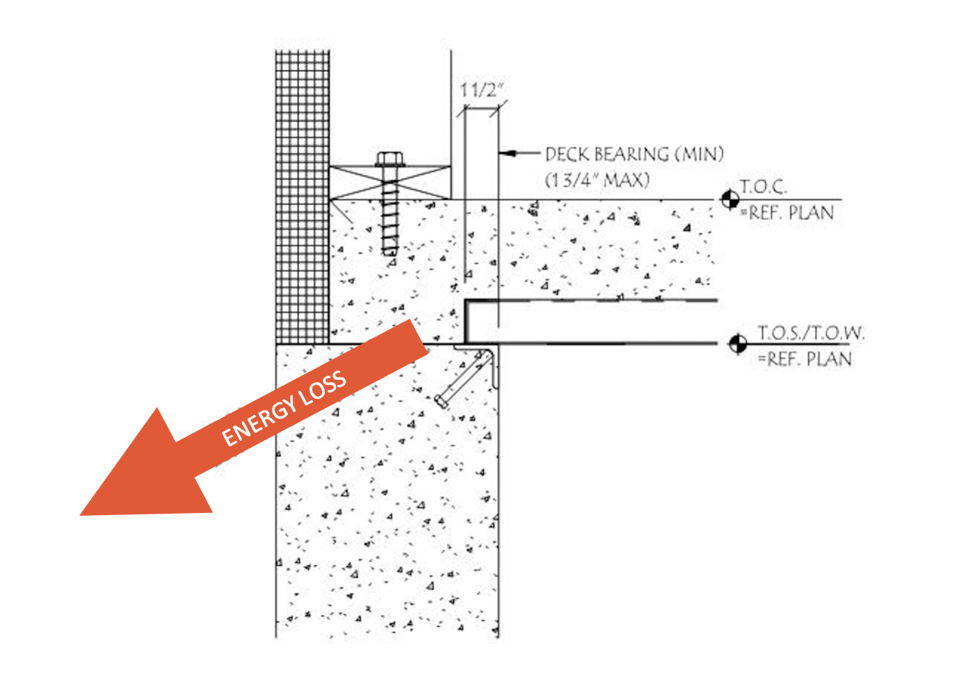

- What are Thermal Breaks?: Thermal breaks are materials or techniques used to interrupt the flow of heat between two surfaces. In the context of basement flooring, thermal breaks serve to prevent heat loss from the interior of the home to the cooler ground below. By creating a barrier between the basement floor and the ground, thermal breaks help maintain a more stable indoor temperature and reduce energy consumption.

- Why are Thermal Breaks Important for Basement Flooring?: Basements are naturally cooler than the rest of the house due to their below-ground location. Without proper insulation and thermal breaks, this temperature difference can lead to discomfort and increased energy bills, especially in colder climates. Introducing thermal breaks helps mitigate heat loss and create a more comfortable living environment in the basement.

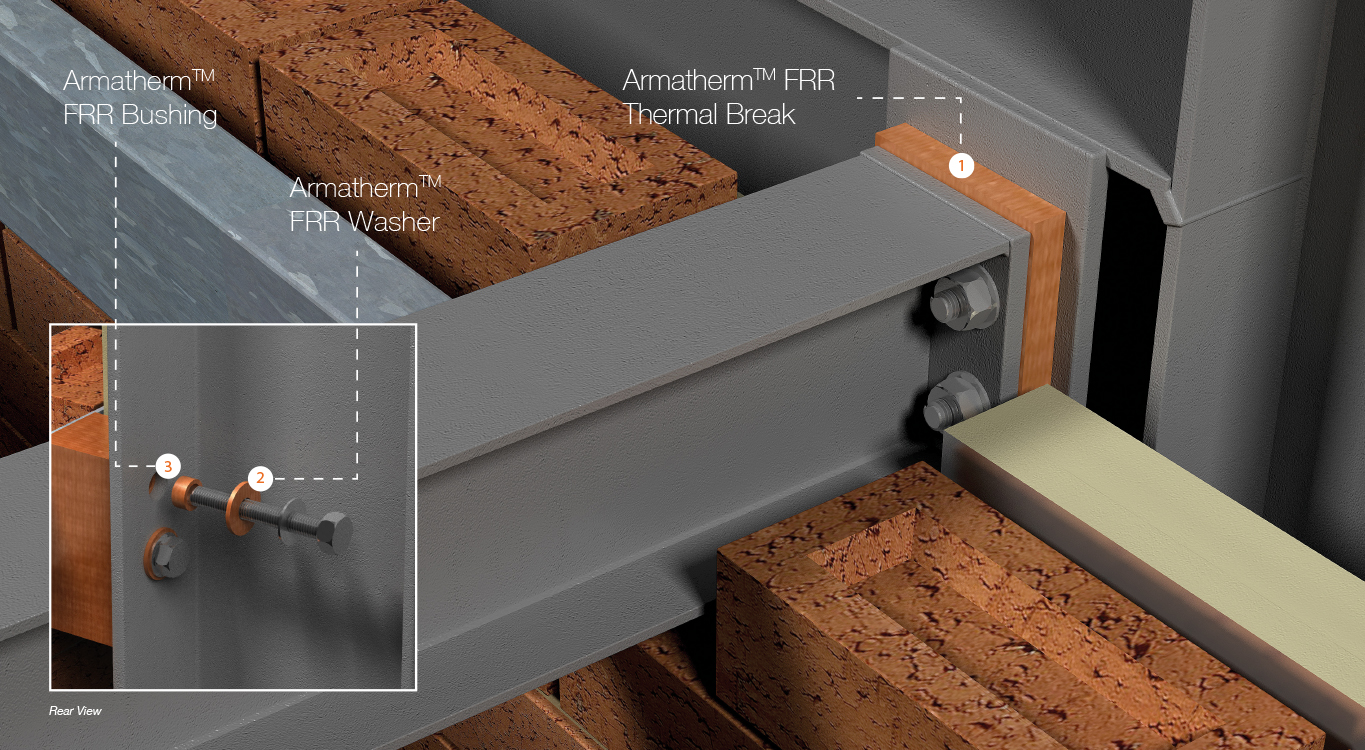

- Types of Thermal Breaks: Thermal breaks can take various forms, including insulation materials, reflective barriers, and structural techniques. Insulation materials like foam boards or spray foam are commonly used to provide a layer of resistance against heat transfer. Reflective barriers, such as foil-backed insulation, reflect radiant heat away from the floor surface. Structural techniques like installing a raised subfloor also create a physical barrier between the basement floor and the ground.

- Installation Considerations: When installing thermal breaks in basement flooring, it’s essential to consider factors such as moisture resistance, compatibility with other flooring materials, and local building codes. Proper installation techniques, including sealing seams and gaps, are crucial for maximizing the effectiveness of thermal breaks and preventing air leakage.

Benefits of Incorporating Thermal Breaks in Basement Flooring

Incorporating thermal breaks into basement flooring offers a range of benefits for homeowners, from improved comfort to energy savings. Below are some of the key advantages of using thermal breaks in basement floors:

Enhanced Comfort: One of the primary benefits of incorporating thermal breaks is enhanced comfort. By reducing heat loss and maintaining a more consistent indoor temperature, thermal breaks create a warmer and more comfortable living environment in the basement. This is particularly beneficial for homeowners who use their basements as living spaces or recreational areas.

Energy Savings: Another significant advantage of thermal breaks is their potential for energy savings. By minimizing heat loss through the basement floor, thermal breaks help reduce the workload on heating systems, resulting in lower energy consumption and utility bills. Over time, the energy savings generated by thermal breaks can offset the initial cost of installation.

Moisture Control: In addition to thermal insulation, some thermal break materials also provide moisture resistance, helping to prevent water damage and mold growth in the basement. By creating a barrier between the floor and the ground, thermal breaks can help keep the basement dry and comfortable year-round.

Improved Indoor Air Quality: By reducing moisture and preventing mold growth, thermal breaks contribute to improved indoor air quality in the basement. This is particularly important for homeowners with respiratory issues or allergies, as mold and dampness can exacerbate these conditions. With proper ventilation and moisture control, thermal breaks help create a healthier living environment.

Durability and Longevity: Many thermal break materials are designed to be durable and long-lasting, providing years of reliable performance with minimal maintenance. Whether you choose foam insulation, reflective barriers, or structural techniques, incorporating thermal breaks into your basement flooring can extend the lifespan of your flooring materials and protect against wear and tear.

Environmental Benefits: From a sustainability standpoint, using thermal breaks in basement flooring can contribute to reducing overall energy consumption and greenhouse gas emissions. By improving the energy efficiency of your home, thermal breaks help lower your carbon footprint and lessen environmental impact.

Installation Options and Techniques for Thermal Break Basement Floors

Installing thermal breaks in basement floors requires careful planning and execution to ensure optimal performance and longevity. Here are some installation options and techniques to consider:

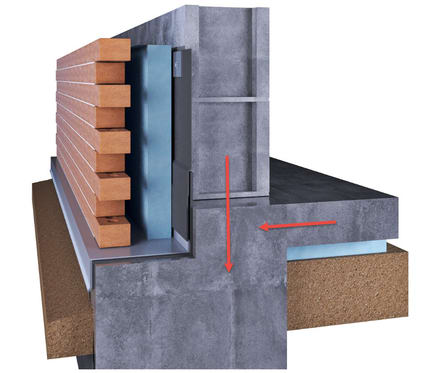

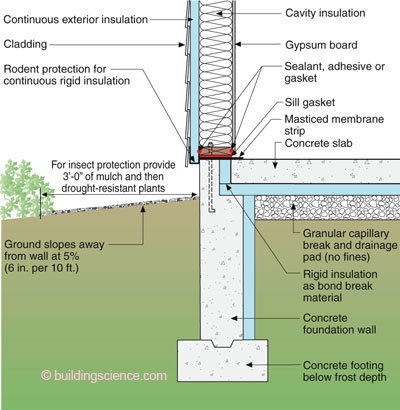

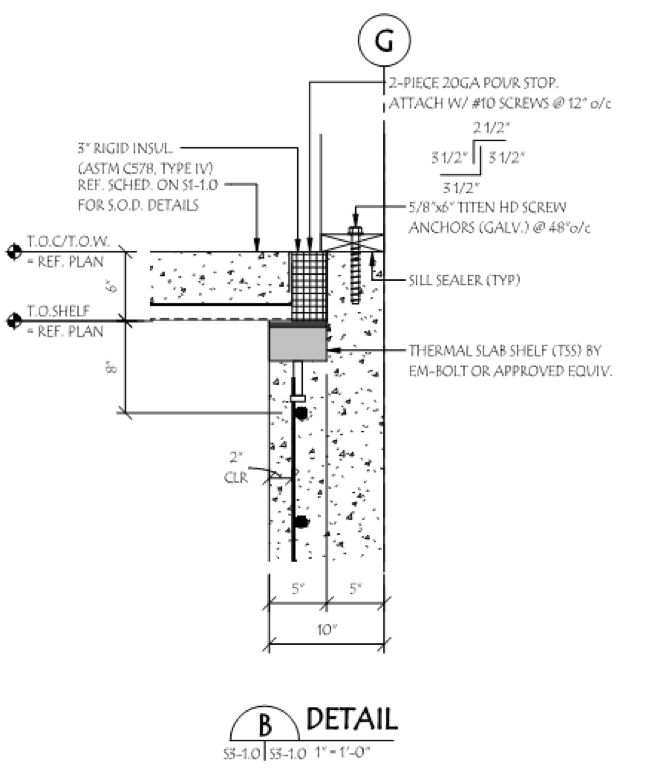

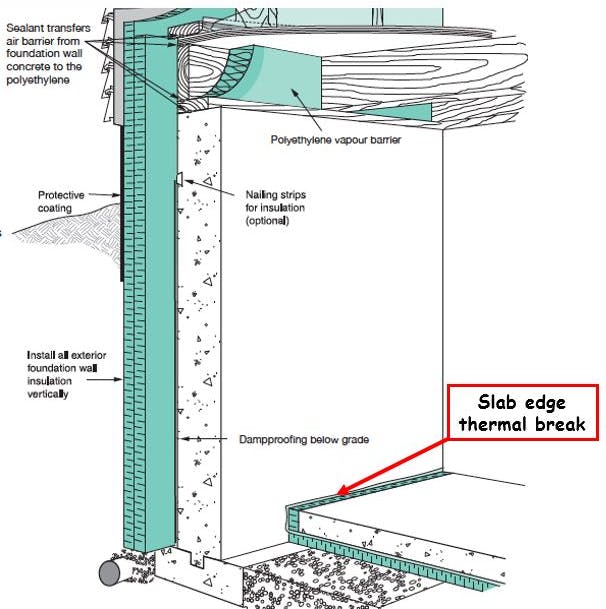

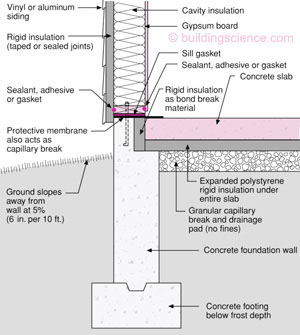

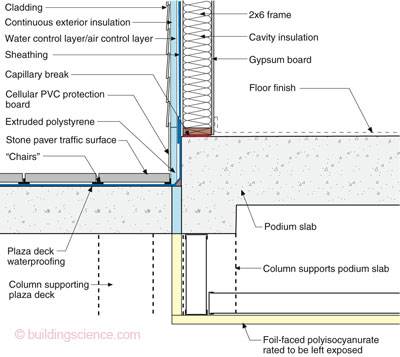

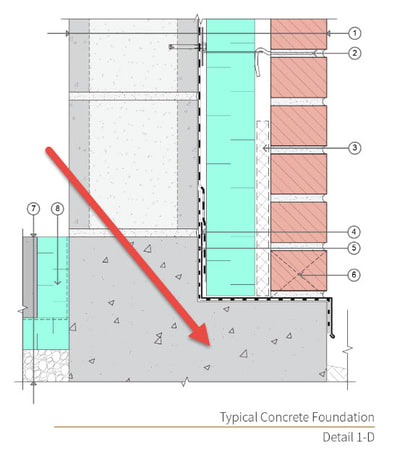

Subfloor Insulation: One of the most common techniques for installing thermal breaks on basement floors is to add insulation beneath the finished flooring material. This can be achieved by laying rigid foam insulation boards directly on top of the concrete slab before installing the subfloor. The insulation boards create a thermal barrier that helps prevent heat loss and moisture penetration from the ground.

Reflective Barrier Installation: Another option for thermal break installation is to use reflective barriers, such as foil-backed insulation or radiant barrier underlayment. These materials are installed directly on top of the concrete slab, with the reflective surface facing upward. Reflective barriers work by reflecting radiant heat away from the floor surface, helping to maintain a more consistent indoor temperature.

Raised Subfloor Systems: For homeowners looking to create a more finished and comfortable living space in the basement, raised subfloor systems offer an effective thermal break solution. These systems consist of interlocking panels or tiles supported by adjustable pedestals, creating a raised platform above the concrete slab. The space beneath the subfloor can be filled with insulation material to provide additional thermal resistance.

Sealing and Vapor Barrier Installation: Proper sealing and moisture control are essential aspects of thermal break installation in basement floors. Before adding insulation or subflooring, it’s crucial to seal any cracks or gaps in the concrete slab to prevent air leakage and moisture infiltration. Additionally, installing a vapor barrier between the concrete slab and the thermal break material helps prevent moisture from seeping into the basement space.

Professional Installation Considerations: While some homeowners may choose to tackle thermal break installation themselves, hiring a professional contractor can ensure proper installation and adherence to building codes and regulations. Professional installers have the expertise and experience to assess the unique requirements of your basement space and recommend the most effective thermal break solutions.

Choosing the Right Materials for Effective Thermal Breaks

Selecting the right materials for thermal breaks in basement floors is crucial for maximizing performance and longevity. Here are some factors to consider when choosing materials for effective thermal breaks:

Insulation Performance: The primary function of thermal break materials is to provide insulation against heat transfer. When selecting insulation materials, consider their R-value, which measures the material’s thermal resistance. Higher R-values indicate greater insulating effectiveness and better heat retention in the basement space.

Moisture Resistance: Basement environments are prone to moisture infiltration, so it’s essential to choose thermal break materials that are resistant to moisture and water damage. Look for insulation materials with built-in vapor barriers or consider adding a separate vapor barrier layer to protect against moisture penetration from the ground.

Durability and Longevity: Basement floors are subject to heavy foot traffic and potential water exposure, so it’s important to choose durable and long-lasting thermal break materials. Insulation boards should be resistant to compression and damage, while reflective barriers should have a robust construction that can withstand wear and tear.

Compatibility with Flooring Materials: Consider the type of flooring material you plan to install over the thermal break layer and choose materials that are compatible with your flooring choice. For example, if you’re installing hardwood or laminate flooring, ensure that the thermal break material provides a smooth and level surface for proper installation.

Environmental Impact: When selecting thermal break materials, consider their environmental impact and sustainability. Look for materials that are made from renewable or recycled sources and have a minimal environmental footprint. Additionally, choose materials that are free from harmful chemicals and emissions to ensure a healthy indoor environment.

Cost and Budget: Finally, consider the cost of materials and installation when choosing thermal break options for your basement floors. While high-performance insulation materials may have a higher upfront cost, they can result in long-term energy savings and improved comfort, making them a worthwhile investment.

Maintenance Tips and Long-Term Considerations for Thermal Break Basement Floors

Once thermal breaks are installed on basement floors, proper maintenance is essential to ensure their continued effectiveness and longevity. Here are some maintenance tips and long-term considerations for thermal break basement floors:

Regular Cleaning: Keep the basement floor clean and free from debris, dust, and spills to prevent damage to the thermal break materials. Use a soft brush or vacuum cleaner to remove dirt and dust, and promptly clean up any spills or stains to prevent staining or deterioration of the flooring materials.

Inspect for Damage: Periodically inspect the thermal break materials for signs of damage, wear, or deterioration. Look for cracks, gaps, or compression in insulation boards, and check for tears or punctures in reflective barriers. Address any issues promptly to prevent further damage and maintain the effectiveness of the thermal breaks.

Monitor Moisture Levels: Keep an eye on moisture levels in the basement and address any signs of moisture infiltration promptly. Use a dehumidifier to maintain optimal humidity levels and prevent condensation buildup, which can compromise the integrity of the thermal break materials and lead to mold growth or water damage.

Repair or Replace Damaged Materials: If you notice any damage or deterioration in the thermal broken materials, take action to repair or replace them as needed. Repair cracks or gaps in insulation boards with sealant or foam insulation, and patch tears or punctures in reflective barriers with appropriate tape or patches. If damage is extensive, consider replacing the affected materials to ensure continued insulation effectiveness.

Seal and Insulate Around Penetrations: Inspect and seal around penetrations such as pipes, vents, or electrical outlets to prevent air leakage and maintain the integrity of the thermal breaks. Use appropriate sealant or insulation materials to seal gaps and ensure a tight seal around penetrations.

Consider Future Renovations: When planning future renovations or upgrades in the basement, consider how they may impact the thermal break materials and take steps to preserve their effectiveness. Coordinate with contractors to ensure that new flooring materials or structural changes do not compromise the integrity of the thermal breaks.

New Thermal Break Concrete Slab Solution Reduces Construction and

Bond break Reshaping our Footprint

Schöck Isokorb® Concrete Slab Edge Thermal Break Applications

The Secret to a Warmer, Drier, Faster Finished Basement – Amvic

Basement / Concrete Slab Insulation Job Preparation Guides

New Thermal Break Concrete Slab Solution Reduces Construction and

Concrete Slab Insulation – peritussprayfoam

Slab Happy u2013 Concrete Engineering Building Science

Insulating a Raised Slab – GreenBuildingAdvisor

Related Posts: