You can find 3 primary types of epoxy for flooring surfaces. Not simply are these types of floorings mechanically strong although they are additionally resistant to chemical elements once they start to be sound as well as being extremely adhesive during the stage when they modified from liquid to the great form you see on most floors today.

Images about Trowel On Epoxy Floor Coating

Trowel On Epoxy Floor Coating

A brand new sort which is actually gaining traction in the industry is epoxy flaked floor. Although this gloss is normal to any kind of epoxy brand, many organizations accomplish this style by setting an extra topcoat over the conventional epoxy mix. Applicators should stick to manufacturer’s suggestions to maintain consistency in texture as well as viscosity.

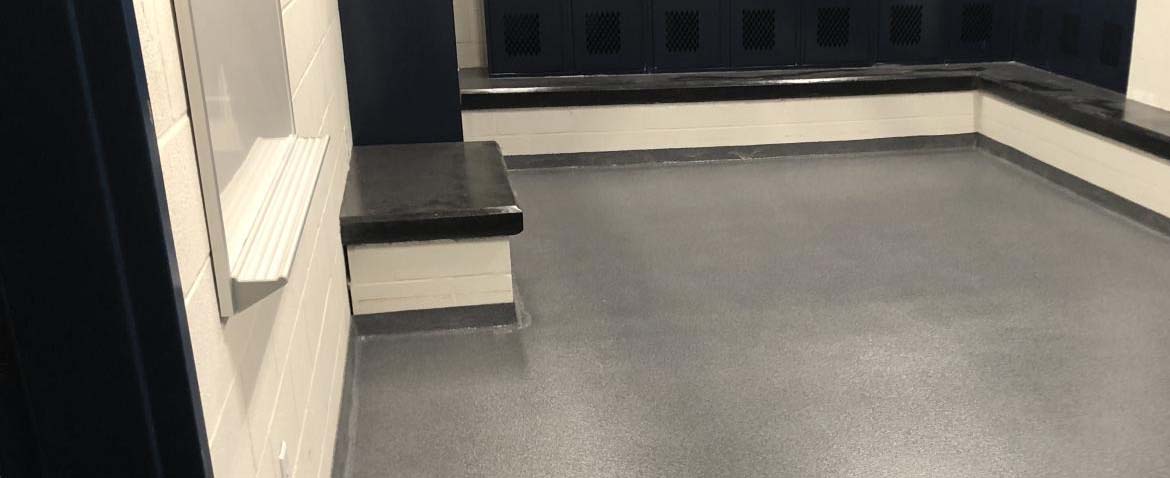

Trowel Down Epoxy Topcoat Epoxy Flooring Case Study – Liquid Floors

Plus you will discover a multitude of fundamental epoxy chemicals which may be worn in order to create epoxy flooring. news which is Good is, you can constantly customize your floor as per your preferences. An epoxy floors is generated when a protective resin is used with the top of a current concrete slab. Including colored silica tends to make the floor appealing.

Epoxy Flooring u2013 Trowel Grade West Coast Epoxy

Trowel Down Epoxy Flooring – Floored Solutions

Broadcast vs Troweled Quartz Systems: Which is Right For Your Job

Broadcast vs Troweled Quartz Systems: Which is Right For Your Job

Steel Trowel Epoxy Coating on Concrete Surface – YouTube

Troweled Integral Cove Base Epoxy Floor Base

Trowel Down Epoxy Flooring – Floored Solutions

Midwest Rake 4 1/4″ V-Notched Trowel

Smooth Troweled Concrete Phoenix Troweled Epoxy Flooring

How To Magic Trowel Epoxy

Related Posts:

- Epoxy Basement Floor DIY

- High Gloss Epoxy Floor

- Decorative Epoxy Flooring

- Epoxy Floor Garage DIY

- DIY Epoxy Kitchen Floor

- Best Epoxy Floor Paint For Garage

- DIY Epoxy Garage Floor

- Metallic Epoxy Floor

- DIY Garage Epoxy Floor

- Indoor Epoxy Flooring

Introduction to Trowel On Epoxy Floor Coating

Epoxy floor coating is the perfect solution for any surface that needs protection from dirt, water, or chemical spills. Trowel on epoxy floor coating is durable, long-lasting, and easy to apply. It can be applied with a trowel or roller, and is great for a wide variety of residential and commercial applications, such as garage floors, warehouses, manufacturing facilities, and retail spaces. It provides an attractive finish while offering maximum protection to the surface.

In this article, we’ll take a look at the benefits of trowel on epoxy floor coating, the key features of the product, how it’s applied correctly, and frequently asked questions (FAQs).

What are the Benefits of Trowel On Epoxy Floor Coating?

Trowel on epoxy floor coating offers many advantages over other floor coatings. First and foremost is its durability. Epoxy coatings are known for their ability to handle heavy traffic and frequent cleanings without needing re-application. It’s also resistant to water and chemical spills, making it ideal for areas in need of extra protection against liquids.

In addition to its durability and protection capabilities, epoxy floor coating is easy to maintain. It doesn’t require intense cleaning or expensive products to keep it looking its best – just a quick mop or sweep every few weeks will do. It can even be resurfaced with a small amount of epoxy if necessary.

Another significant benefit of trowel on epoxy flooring is its aesthetic value. Epoxy coatings come in a variety of colors and can be customized with logos or designs. This makes them perfect for showrooms or commercial spaces where you want to attract customers with an attractive finish.

Lastly, trowel on epoxy flooring is cost effective. Since it lasts longer than other types of floor coatings, you’ll save money by not having to replace it very often. Plus, its easy installation process means you don’t need to hire a professional contractor – you can do-it-yourself and save even more money in the long run.

Key Features of Trowel On Epoxy Floor Coating

Trowel on epoxy floor coatings have several key features that make them an attractive option for both residential and commercial applications.

First off, they come in a variety of colors and finishes. You can customize your flooring with logos or designs for showroom spaces or pick out one of the many solid colors available for more subtle looks.

Trowel on epoxies are also incredibly durable and resistant to scratches from traffic or water damage from spills. This makes them great for garages or warehouses that experience a lot of wear and tear over time.

Lastly, these coatings are low maintenance – all they need is a quick mop or sweep to keep them looking their best. And if they do need touching up, you can easily add a layer of epoxy yourself without needing to hire a professional contractor.

How To Apply Trowel On Epoxy Floor Coating?

Applying trowel on epoxy floor coating is fairly straightforward process that can be done without help from a professional contractor. The first step is to prepare the surface by cleaning it thoroughly with soap and water. This will remove any dirt or debris that could interfere with the application process.

Next, use a degreaser or chemical cleaner to remove any oil or grease from the surface – these substances can interfere with the adhesion of the epoxy coating so it’s important to make sure they’re completely gone before you start applying the coating materials. Once that’s done, you’re ready to start applying!

Using either a trowel or roller (depending on your preference), begin spreading the material evenly across the surface in long strokes. The goal is to get an even coat so take your time and make sure each area has been properly covered before moving on to another section. Once you have finished covering the entire surface, let the material dry for 24 hours before using it again – this will ensure that it has achieved its optimal strength And durability.

What is the best trowel for applying epoxy floor coating?

When applying epoxy floor coating, the best trowel to use is a metal trowel with a flat blade. This type of trowel provides maximum surface coverage and helps ensure a level, even finish. Additionally, it’s important to select a trowel size specific to the size of the area that needs to be covered; 4-inch, 6-inch, or 8-inch trowels are typically used for epoxy floor coating applications.

What type of trowel should be used to apply epoxy floor coating?

A notched squeegee trowel should be used to apply epoxy floor coating. These types of trowels are designed specifically for epoxy floor coatings and will help ensure an even application for the best results.

What is the best way to prepare a floor for epoxy coating?

The best way to prepare a floor for epoxy coating is to ensure it is clean, dry, and free of debris. It is also important to remove any existing paint or sealant on the floor prior to applying the epoxy coating. For concrete floors, it is important to diamond grind the concrete surface in order to provide a better bonding surface for the epoxy. If necessary, use a crack filler or patching compound to repair any cracks or chips in the concrete surface. Finally, vacuum or sweep the surface to remove any dust or debris prior to applying the epoxy coating.

What is the difference between paint and epoxy coating?

Paint is a liquid or semi-liquid material that forms a thin, decorative, and protective surface when applied to an object. Paint is usually used to improve the appearance of a surface and protect it from weather and corrosion. Epoxy coating, on the other hand, is a much thicker and stronger material. It provides a waterproof barrier that is highly resistant to wear, chemical exposure, corrosive environments, and even high temperatures. Epoxy coatings are often used in industrial applications because of their superior performance and durability.

What are the advantages of epoxy coating over paint?

1. Durability: Epoxy coatings are more durable and longer lasting than paint, with some formulations capable of lasting up to 15 years or more with little to no maintenance.

2. Chemical resistance: Epoxy coatings are much more resistant to harsh chemicals than paint, which makes them ideal for industrial or commercial use.

3. Abrasion resistance: Epoxy coatings are much better at resisting abrasion than paint, making them ideal for use in high-traffic areas or in applications subject to wear and tear.

4. Low-maintenance: Epoxy coatings require very little upkeep once they’ve been applied, making them an ideal choice for those looking for a low-maintenance flooring solution.

5. Optimal color: When mixed, epoxy provides a smoother, more uniform finish than paint, resulting in optimal color consistency and a beautiful end product.