Unlocking the Secrets of Wood Floor Framing Design

Wood floor framing design is the backbone of any construction project, ensuring the creation of a robust and enduring structural framework for wooden floors. Let’s talk about the intricacies of this essential aspect of building construction through the following key points:

Foundation of Stability: Understanding the Basics

- Wood floor framing design is the meticulous process of creating a structural framework for wooden floors.

- It guarantees stability, strength, and durability while supporting diverse loads and withstanding external forces.

Components Crafting: Joists, Beams, and Supports

- The design involves the selection and arrangement of components like joists, beams, and supports.

- These elements are strategically positioned to form a solid and reliable structure.

Weight Distribution Mastery: Achieving Balance

- The primary objective is even weight distribution, encompassing live loads, dead loads, and other factors.

- Considerations include span lengths, deflection limits, and strict adherence to building codes.

Material Selection: Crafting with Precision

- Choosing the right materials is pivotal, with options ranging from dimensional lumber to engineered wood products.

- Factors such as load capacity, moisture resistance, and cost-effectiveness guide material selection.

Layout and Spacing Calculations: Precision Matters

- Determining the layout and spacing involves calculating allowable spans for joists and beams.

- Factors like size, grade, and wood species play a crucial role, in ensuring precision in spacing and distribution.

Connection Chronicles: Ensuring Stability

- Properly designed connections are critical for overall stability and strength.

- Fasteners like nails or screws, along with engineered metal connectors, secure framing members together.

Future-Proofing: Adaptability for Tomorrow

- Wood floor framing design anticipates potential modifications or renovations.

- It allows for easy access to utilities and provides flexibility for changes in floor layout or usage.

The Importance of Wood Floor Framing Design:

Wood floor framing design plays a crucial role in the stability and longevity of a building. It is a key component that provides support and structural integrity to the entire structure. A well-designed wood floor framing system ensures that the load-bearing capacity is sufficient to withstand the weight of the occupants, furniture, and other loads imposed on the floor.

One of the primary benefits of a properly designed wood floor framing system is its ability to distribute the loads evenly across the entire structure. This helps prevent excessive stress on individual components and minimizes the risk of structural failure. Additionally, a well-designed wood floor framing system can contribute to the overall stability of the building, reducing the likelihood of issues such as sagging or excessive movement.

Key Factors to Consider in Wood Floor Framing Design:

When designing a wood floor framing system, several key factors need to be considered. These factors include the span of the floor, the expected loads, the type and quality of wood used, and the connection details.

The span of the floor refers to the distance between the supporting walls or beams. It is important to determine the appropriate span based on the expected loads and the type of wood being used. The span directly affects the load-carrying capacity and deflection of the floor.

The expected loads on the floor should be carefully considered to ensure that the wood floor framing system can adequately support them. This includes considering the weight of the occupants, furniture, and any additional loads that the floor may be subjected to, such as heavy equipment or storage.

The type and quality of wood used in the framing system is another critical factor to consider. Different types of wood have varying load-bearing capacities and resistance to decay or insect damage. It is important to select a suitable wood species that meets the structural requirements and can withstand the environmental conditions.

Proper connection details are essential for ensuring the strength and stability of the wood floor framing system. The connections between the floor joists, beams, and supporting walls or columns should be carefully designed and constructed to prevent any weak points or potential failure zones.

Types of Wood Floor Framing Systems

There are several types of wood floor framing systems commonly used in construction projects. Each system has its own unique characteristics and advantages. The choice of framing system depends on factors such as the span requirements, load-bearing capacity, and budget constraints. The following are some of the most commonly used wood floor framing systems:

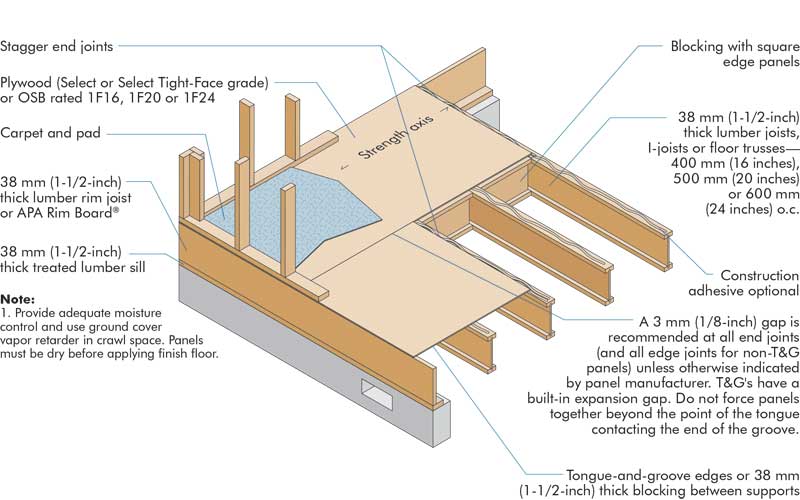

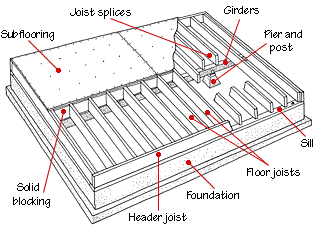

- Joist and Beam System: This is the most traditional and commonly used wood floor framing system. It involves the use of solid wood joists that are supported by wood beams. The joists are typically spaced at regular intervals and are connected to the beams using nails or screws. This system provides excellent load-bearing capacity and is suitable for both residential and commercial applications.

- I-Joist System: The I-joist system is a more modern approach to wood floor framing. It involves the use of engineered wood I-joists, which are lightweight yet strong. These joists are manufactured by sandwiching a web of plywood or oriented strand board between two flanges of solid wood. The I-joists are spaced at regular intervals and are attached to supporting beams using metal hangers. This system offers excellent strength-to-weight ratio, allowing for longer spans and reducing the need for intermediate supports.

- Open Web Truss System: The open web truss system is another popular choice for wood floor framing. It involves the use of prefabricated trusses made of wood or metal. These trusses consist of a network of diagonal and vertical members, creating an open web design. The trusses are designed to span long distances and provide excellent load-bearing capacity. They are typically installed on top of supporting beams or walls and require minimal on-site assembly.

- Steel Joist System: In some cases, steel joists may be used instead of wood for floor framing. Steel joists are lightweight yet strong, making them ideal for applications where longer spans are required. They are typically manufactured as C-shaped or S-shaped sections, which can be easily connected using bolts or welds. Steel joists are commonly used in commercial and industrial buildings, where their fire resistance and durability are highly valued.

- Post and Beam System: The post and beam system is a more traditional and rustic approach to wood floor framing. It involves the use of large solid wood beams supported by vertical posts. This system allows for greater design flexibility, as the beams can be spaced at wider intervals.

Wood Floor Framing Design

When it comes to wood floor framing systems, there are various options available, including platform framing, balloon framing, and post and beam framing. Each of these systems has its own advantages, disadvantages, and suitable applications. Understanding the characteristics of each design can help readers choose the most appropriate one for their specific needs.

- Platform Framing: Platform framing is the most commonly used wood floor framing system in modern construction. This method involves building the floor one level at a time, starting with the foundation and adding walls, floors, and roofs as separate entities. The advantages of platform framing include its simplicity, cost-effectiveness, and ease of construction. It allows for greater flexibility in design and offers efficient insulation options. However, platform framing may not be suitable for areas with high seismic activity or extreme weather conditions.

- Balloon Framing: Balloon framing, once a popular method, is less commonly used today but still has its merits. This system involves constructing long vertical studs that extend the full height of the building, from the foundation to the roof. The advantages of balloon framing include its open and spacious interior, as it eliminates the need for horizontal plates between floors. It also allows for longer spans and fewer load-bearing walls. However, balloon framing requires careful detailing to ensure fire safety and may not be suitable for buildings with multiple stories.

- Post and Beam Framing: Post and beam framing is a traditional method that utilizes vertical posts and horizontal beams to support the floor structure. This design provides a rustic and timeless appearance and allows for large open spaces. The advantages of post and beam framing include its aesthetic appeal, versatility in design, and the ability to use a variety of materials. It also allows for high ceilings and easy installation of utilities. However, post and beam framing can be more expensive and time-consuming compared to other systems. It may also require additional insulation and may not be suitable for buildings with heavy loads or in areas prone to earthquakes.

Considerations for Designing Wood Floor Framing

Load Requirements:

When designing wood floor framing, it is crucial to consider the load requirements that the floor will need to support. This includes both dead loads, such as the weight of the flooring material and any permanent fixtures, as well as live loads, such as furniture and occupants. Understanding the specific load requirements will help determine the size and spacing of the floor joists and the overall structural integrity of the wood floor framing.

Span Length:

The span length refers to the distance between the supports or walls that the floor joists will be attached to. The longer the span, the greater the deflection or sagging of the floor may be. It is important to consider the span length when designing the wood floor framing to ensure that the appropriate size and spacing of the joists are used to minimize deflection and maintain a level, sturdy floor.

Lumber Grade and Species:

The choice of lumber grade and species can significantly impact the strength and durability of the wood floor framing. Different lumber grades have specific strength properties, and selecting the appropriate grade based on the load requirements is crucial. Additionally, certain wood species have higher strength properties than others, which may be beneficial in supporting heavier loads or improving the overall performance of the floor framing.

Moisture Considerations:

Wood is susceptible to moisture, which can lead to dimensional changes, rot, and decay. When designing wood floor framing, it is essential to consider moisture sources such as humidity, moisture from the ground, or potential leaks. Proper moisture management techniques, such as providing adequate ventilation and using moisture-resistant materials, should be incorporated into the design to prevent structural damage and ensure the longevity of the wood floor framing.

Building Codes and Regulations:

Compliance with local building codes and regulations is essential when designing wood floor framing. These codes provide minimum requirements for structural safety and performance. It is crucial to be familiar with the specific codes applicable to the project location and ensure that the wood floor framing design meets or exceeds these requirements. Working with a qualified structural engineer or architect can help ensure compliance with building codes and regulations.

Accessibility and Future Modifications:

Consideration should be given to the accessibility of the wood floor framing for future maintenance or modifications. Incorporating access points, such as crawl spaces or removable panels, can facilitate inspections, repairs, or future renovations without causing significant disruption to the flooring above.

Best Practices for Wood Floor Framing Design

Accurate Measurements and Planning

– Before starting any wood floor framing design, it is crucial to take accurate measurements of the space and plan accordingly. This includes determining the size and layout of the floor, as well as considering any load-bearing requirements.

Proper Spacing and Framing Techniques

– When designing wood floor framing, it is important to ensure proper spacing between the floor joists. This not only provides support but also prevents sagging or bouncing of the floor. Additionally, using appropriate framing techniques, such as using double joists or sistering joists, can enhance the overall strength and stability of the wood floor.

Selecting the Right Materials

– Choosing the right materials for wood floor framing is essential to ensure durability and longevity. It is recommended to use high-quality, pressure-treated lumber that is resistant to moisture and decay. Additionally, using engineered wood products, such as I-joists or laminated veneer lumber, can offer increased strength and stability.

Consideration of Load Requirements

– Wood floor framing design should always take into account the load requirements of the intended use. This includes considering the weight of the permanent and temporary loads that the floor will bear. Adequate support and reinforcement should be incorporated to ensure the floor can safely handle the intended loads.

Proper Ventilation and Moisture Control

– Incorporating proper ventilation and moisture control measures in wood floor framing design is essential to prevent issues such as mold growth, rot, or cupping of the wood. Adequate ventilation can help in reducing moisture buildup and maintaining the structural integrity of the floor.

Regular Inspections and Maintenance

– To ensure the longevity and safety of the wood floor framing, regular inspections and maintenance are crucial. Periodic checks for any signs of damage, such as cracks, warping, or decay, should be conducted. Prompt repairs or replacements should be made to prevent further damage and maintain the structural integrity of the floor.

Compliance with Building Codes and Regulations

– Wood floor framing design should adhere to local building codes and regulations to ensure compliance with safety standards. It is important to consult with a professional engineer or architect to ensure that the design meets all necessary requirements.

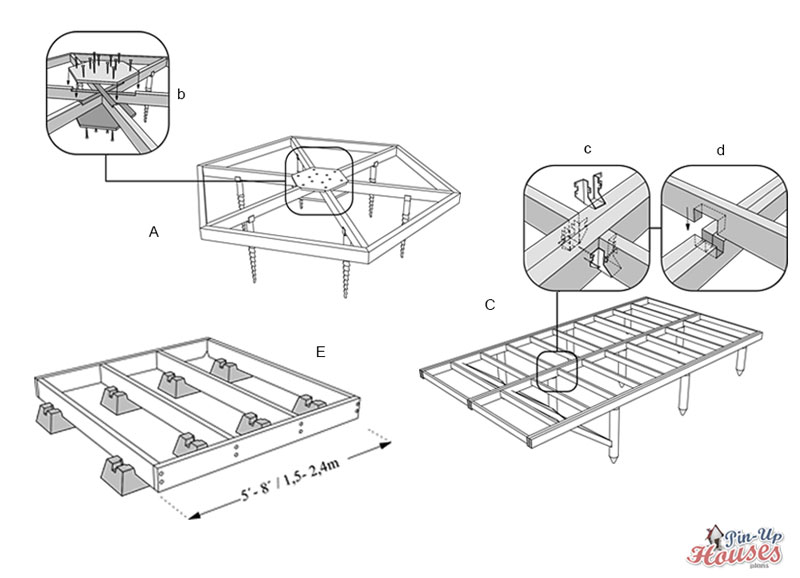

Cabin Floor Framing – DIY Timber Floor Framing Construction

How to Frame a Floor: 12 Steps (with Pictures) – wikiHow

Wooden Floor Framing

Design considerations in engineered wood floor systems – Page 3 of

Revit Turbocharger for Timber Frame Floors u2013 BIM Software

How to Frame a Floor: 12 Steps (with Pictures) – wikiHow

Related Posts: