If you’re like me, you take pride in your garage as more than just a place to park your car. It’s a workshop, a storage space, and sometimes even a hangout spot. But to make the most of this versatile space, you need a flooring solution that can handle it all. That’s where 2-part epoxy garage floor coating comes in. In this comprehensive guide, I’ll walk you through the benefits of this fantastic flooring option, the step-by-step application process, and essential tips to ensure your garage floor is not only durable but also aesthetically appealing.

Advantages of 2-Part Epoxy Garage Floor Coating

Unparalleled Durability and Longevity

When it comes to garage floors, durability is a top priority. 2-part epoxy garage floor coating offers unbeatable strength, making it resistant to impacts, heavy loads, and constant foot traffic. With this coating, you won’t have to worry about chipping, cracking, or wearing out over time.

Chemical and Stain Resistance for Garage Spills

Garages are notorious for spills and stains, from oil and grease to household chemicals. The chemical resistance of 2-part epoxy garage floor coating ensures that these spills won’t penetrate the surface, making cleanup a breeze and preventing unsightly stains from setting in.

Enhanced Adhesion for Lasting Performance

The 2-part epoxy system combines a resin and a hardener, creating a strong bond that adheres tightly to the concrete floor. This superior adhesion ensures that the coating stays in place, even under the demands of daily garage use.

High-Gloss Finish for Aesthetic Appeal

Beyond its practical benefits, 2-part epoxy coating adds a high-gloss finish to your garage floor. This glossy sheen reflects light, brightening up the space and giving it a professional, showroom-like appearance.

Cost-Effectiveness and Return on Investment

While the upfront cost of 2-part epoxy garage floor coating may be higher than other flooring options, its long-lasting durability and low maintenance requirements make it a cost-effective investment in the long run. You’ll save money on repairs and replacements, and your garage will maintain its pristine look for years to come.

Understanding 2-Part Epoxy Garage Floor Coating

What exactly is 2-part epoxy, and why is it an excellent choice for garage floors?

2-part epoxy garage floor coating is a two-component system consisting of a resin and a hardener. When combined, these components undergo a chemical reaction that results in a strong, cross-linked bond. This chemical bond creates a dense and durable surface that can withstand the daily wear and tear of garage activities.

The curing process of 2-part epoxy involves a chemical reaction that transforms the liquid mixture into a solid polymer. This process usually takes around 24 to 48 hours for the coating to dry and cure, depending on environmental conditions like temperature and humidity.

There are various formulations and varieties of 2-part epoxy coatings available, catering to different needs and preferences. Some formulations offer additional features, such as rapid curing times or UV resistance, making it essential to choose the one that best suits your specific garage requirements.

Applying 2-Part Epoxy Garage Floor Coating

Before embarking on the application process, proper preparation is key to ensuring a successful and long-lasting finish.

Preparing the Garage Floor for Coating

- Clearing and Cleaning the Space – Begin by removing all items and clutter from your garage to create a clear workspace. Sweep or vacuum the floor thoroughly to remove dust and debris.

- Repairing Cracks and Imperfections – Inspect the floor for any cracks or imperfections and patch them up using a suitable concrete patching compound. Addressing these issues beforehand ensures a smooth and even surface for the epoxy coating.

- Addressing Oil Stains and Contaminants – Garages are prone to oil spills and other contaminants. Use a degreaser or an oil-stain remover to clean the affected areas thoroughly. Proper cleaning ensures that the epoxy adheres securely to the floor without interference from residues.

Mixing and Applying the Epoxy Coating

Now that your garage floor is prepped and ready, it’s time to apply the 2-part epoxy coating:

- Proper Mixing Ratio and Technique – Follow the manufacturer’s instructions to mix the epoxy resin and hardener in the correct ratio. Proper mixing is crucial for ensuring the coating cures effectively and provides the desired strength and durability.

- Step-by-Step Application Process – Apply the epoxy coating evenly across the floor using a paint roller. Work in small sections to ensure the coating is spread evenly, and avoid overlapping to prevent streaks or bubbles in the finish.

- Achieving a Smooth and Even Finish – To achieve a smooth and even finish, take your time during the application process. Pay attention to corners and edges, ensuring that every part of the floor is coated evenly.

Tips for a Successful 2-Part Epoxy Coating Application

To achieve the best results with your 2-part epoxy garage floor coating, consider the following tips:

- Temperature and Humidity Considerations – Epoxy coating cures best within a specific temperature and humidity range. Check the manufacturer’s guidelines for optimal conditions to ensure a successful application.

- Working with Safety Precautions in Mind – Wear appropriate safety gear, such as gloves, goggles, and a respirator, during the application process to protect yourself from potential fumes and skin irritation.

- Using Primers and Sealers for Enhanced Adhesion – Consider using a primer or sealer before applying the epoxy coating to improve adhesion and extend the life of the coating.

- Adding Decorative Elements (optional) – For a touch of personalization, consider adding decorative elements like color flakes or metallic pigments to the wet epoxy. This adds a unique and customized look to your garage floor.

- Ensuring Proper Ventilation during Application – During the application process, ensure proper ventilation in your garage to allow fumes to dissipate. Open windows or use fans to circulate air and prevent a buildup of fumes.

Maintaining and Extending the Life of Your Epoxy-Coated Garage Floor

To ensure your newly coated garage floor maintains its beauty and durability, consider the following maintenance tips:

- Post-Application Curing and Drying Period – After applying the epoxy coating, allow it to cure and dry fully before resuming regular garage use. Follow the manufacturer’s recommended curing time for the best results.

- Long-Term Maintenance and Cleaning – Regularly sweep or dust mop the floor to remove dirt and debris. Clean up spills promptly to prevent stains and ensure your garage floor remains pristine.

- Addressing Scratches and Minor Repairs – In the event of minor scratches or damages, you can use epoxy repair kits to touch up the affected areas easily.

- Preventative Measures to Avoid Damage – Consider placing mats or protective pads under heavy objects, such as tool chests or workbenches, to prevent scratches or indentations on the epoxy-coated surface.

2-part epoxy garage floor coating offers an exceptional solution for transforming your garage into a durable, aesthetically pleasing, and long-lasting space. With its unparalleled strength, chemical resistance, and high-gloss finish, epoxy coating provides an ideal surface for a variety of garage activities. By following the proper application process and adhering to maintenance tips, your epoxy-coated garage floor will not only withstand the test of time but also enhance the overall look and functionality of your garage. So, roll up your sleeves, unleash your DIY spirit, and give your garage the upgrade it deserves with 2-part epoxy garage floor coating!

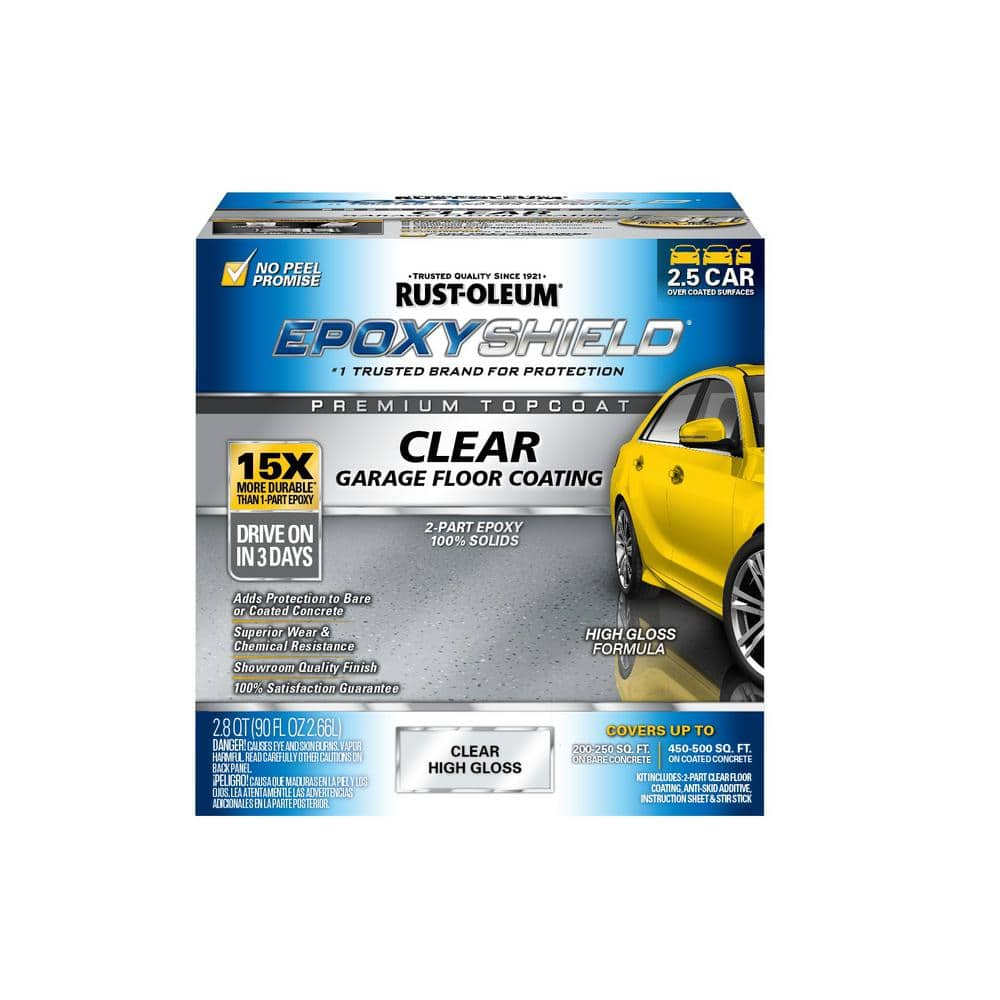

Epoxy-Coat 2-part White High-gloss Concrete and Garage Floor

Rust-Oleum EpoxyShield 240 oz. Gray High-Gloss 2.5-Car Garage

2 part epoxy paint: Buy, Best, Floor, System, 2020 – Concrete

Related Posts:

- Epoxy Garage Floor Coating

- Garage Floor Paint Green

- Garage Floor Resin

- Concrete Garage Floor Design

- Garage Floor Epoxy Ideas

- DIY Garage Floor Tiles

- Car Garage Floor Tiles

- Garage Floor Epoxy Paint

- Garage Floor Paint

- Garage Floor Epoxy Finish