The main reason is the fact that these floors are high efficiency flooring options and definately will last for many years. The most difficult thing is waiting: When the whole concrete floor is done, you still must hold off parking the automobile on it for another 72 hours. But there are concrete floors which appear plain and gray just like those found in factories and garages.

Concrete Floor Anchor Points: Images

Concrete Floor Anchor Points

Another elegant and simple way of utilizing polished concrete that will also decrease costs on the new home project of yours is actually making the foundation a full slab that even functions as the floor. Finally, polished concrete may be utilized not only for your flooring. Concrete cleaners are specifically developed to get rid of ground in dirt and leave behind a pleasing sparkle on polished concrete floor. This is a cost effective way of adding value to your property.

Urban Security UR55 Ground Anchor Wall Anchor, Heavy Duty Security Anchor Motorcycle Security Bike Security, Anchor Point Concrete Floor Anchor

The process of polishing concrete floors is pretty technical and demands some heavy duty machinery designed for that purpose in addition to a technically able individual to run the machine. You are going to want to consider those of skid resistant coatings instead of the glossier finishes. Concrete floors can be decorated in a variety of colors and hues and in addition stamped with different designs.

Security Anchors – Ground Anchors – Wall Anchors Insight Security

Concrete Anchors for Fall Protection – Concrete Decking and

10K Plate Rigging Pick Point

Ground Anchor: how to choose and fit the best protection for your

Porto-Power Shop Floor Anchor Pot u2014 3 1/8in. Diameter, Model# B93075

Concrete in Ground Anchors Insight Security

Champ Floor Anchor Pot u2013 1 Pot u2013 3-1/2 In Diameter – 3/8 In Chain Grommet Thickness – 4 In Sleeve Height – Professional – Made in USA

1,666 lb. Recessed Anchor Ring

Amazon.com: Champ Floor Anchor Pot u2013 1 Pot u2013 3-1/2 In Diameter – 3

Concrete Anchors for Fall Protection – Concrete Decking and

Concrete in Ground Anchors Insight Security

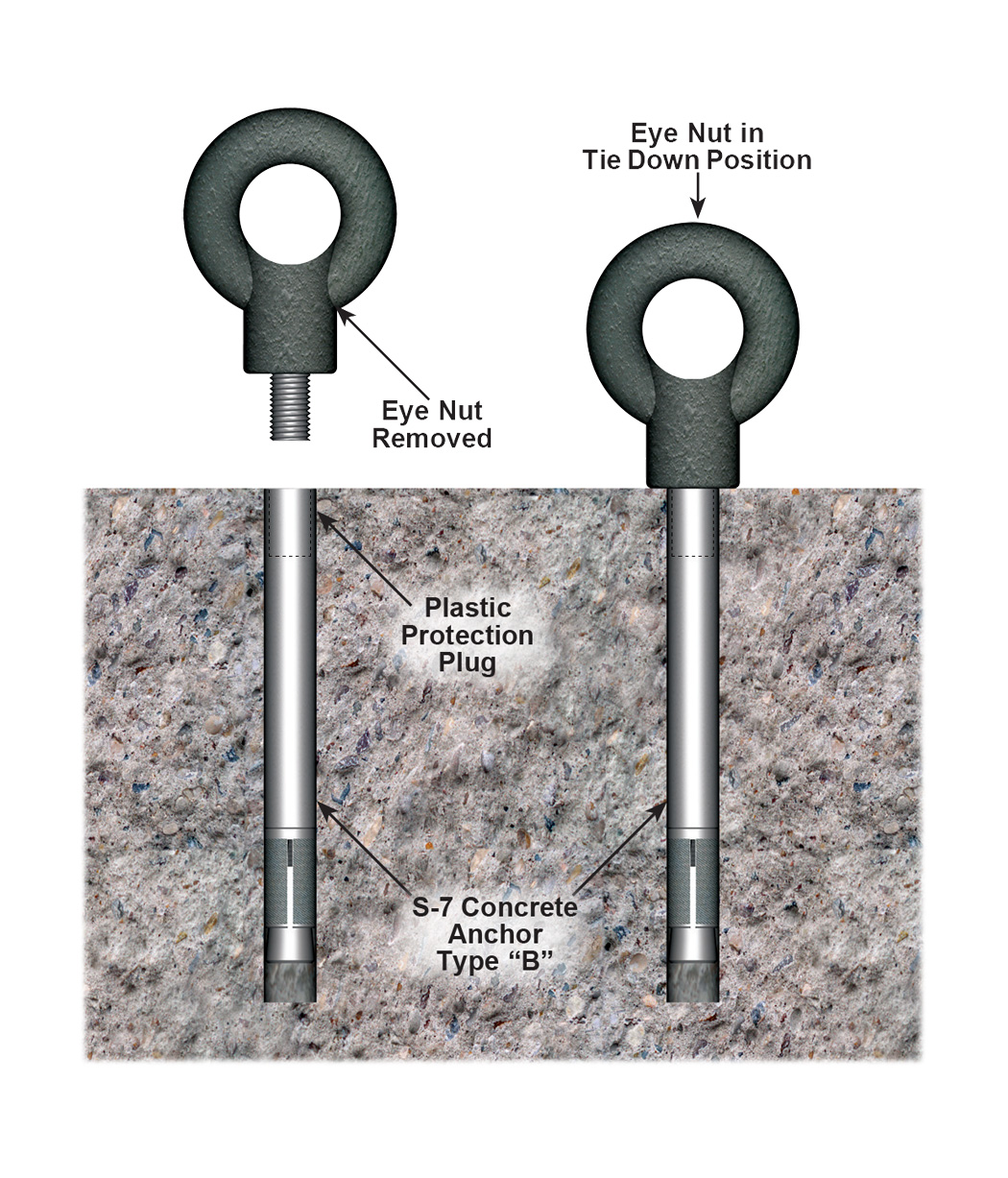

S-7 Reusable Concrete Anchor u2013 Williams Form Engineering Corp.

Related Posts:

- Acid Wash Concrete Floor Colors

- Concrete Floor Thickness For A Garage

- Concrete Floor For Bathroom

- Interior Concrete Floor Ideas

- Kitchen Stained Concrete Floors

- Concrete Floor Tile Thickness

- How To Stain Concrete Floors DIY

- DIY Concrete Floor Grinding

- Concrete Floor Damage

- Faux Stained Concrete Floors

What Are Concrete Floor Anchor Points?

Concrete floor anchor points are secure connections used to hold structural elements and equipment in place. They are fastened to the floor of a building, providing strong and reliable support for safety systems and tools. Anchor points are commonly used in construction, industrial, and manufacturing settings where stability is essential.

Benefits of Concrete Floor Anchor Points

Concrete floor anchor points offer a range of benefits to businesses and organizations. They provide a secure and reliable connection while also increasing the safety of workers, customers, and visitors. Additionally, anchor points can help reduce product damage due to their secure connection to the floor. They also increase the efficiency of processes by ensuring that equipment is securely fastened in place.

Types of Concrete Floor Anchor Points

There are several types of concrete floor anchor points, each with its own set of advantages and disadvantages. The most common types include:

– Wedge anchors: Wedge anchors are designed to be inserted into pre-drilled holes, providing a secure connection for heavy equipment. They can be used with a variety of materials, including concrete, brick, and mortar.

– Sleeve anchors: Sleeve anchors are designed for use with concrete or masonry walls. They are easy to install and provide a strong connection for heavy equipment.

– Drop-in anchors: Drop-in anchors provide a secure connection for heavy loads in concrete floors or walls. They feature an internal thread that allows them to be installed quickly and easily.

– Lag shields: Lag shields provide secure connections for heavy loads in concrete and masonry walls. They are inserted into predrilled holes and secured with lag screws.

How Are Concrete Floor Anchor Points Installed?

The installation process for concrete floor anchor points will vary depending on the type of anchor point being used. For example, wedge anchors typically require pre-drilled holes while drop-in anchors require no pre-drilling. It’s important that the holes are drilled accurately to ensure a secure connection and prevent damage to the surrounding material. Additionally, it’s important that the correct type of anchor is used for the application as some anchors may not be suitable for certain materials or weights.

Conclusion

Concrete floor anchor points offer a range of benefits to businesses and organizations by providing a secure connection for heavy equipment and increasing worker safety. There are several types of anchor points available on the market, each with its own set of advantages and disadvantages. It’s important to select the correct type of anchor for the application as some anchors may not be suitable for certain materials or weights. Additionally, it’s also important to ensure that holes are drilled accurately to ensure a secure connection and prevent damage to the surrounding material during installation.