An extremely small budget may encourage you to accomplish the concreting process on your own. A concrete floor also functions as an excellent base for installation of other flooring products like carpets, tiles and hardwood. Concrete flooring is in addition a practical alternative for kitchens and bathroom where they are quickly cleaned and therefore are unwilling to water.

Images about Concrete Floor Cure Time

Concrete Floor Cure Time

Today's concrete for flooring comes in a broad range of unique colors, and it is feasible to include in a number of other materials and different stone to make a polished concrete floor a point of attractiveness. Concrete flooring has appeal which is great for those excited about environmentally friendly construction.

Role of Concrete Curing

The polished floors are among the best methods to maintain the right floors while in maintaining with' green' observance because concrete flooring doesn't call for addition of other raw materials or perhaps substances, which would otherwise put a force on the planet. Conversely, concrete pulls the heat from the sun in the winter season, hence your flooring continues to be warm.

Curing – Main

Curing In Construction Concrete Cure Time Methods of curing

Role of Concrete Curing

Concrete Curing Time: How Long Does Concrete Take To Dry

Curing of Concrete, Curing Time And Duration, Curing Methods

How long does concrete need to cure in order to reach 90% strength

How Long Does Concrete Take To Set? Concrete Setting Times

Concrete Crack u0026 Damage by Temperature Concrete Curing at High or

Curing of Cement Concrete – Time and Duration – The Constructor

What is the minimum curing time for cement concrete? – Quora

Cement Curing and Setting Time

When is a concrete floor slab dry? BRANZ Build

Related Posts:

- Polished Concrete Floors For Patios

- White Concrete Floor Tiles

- Acid Wash Concrete Floor Colors

- Concrete Floor Thickness For A Garage

- Concrete Floor For Bathroom

- Interior Concrete Floor Ideas

- Kitchen Stained Concrete Floors

- Concrete Floor Tile Thickness

- How To Stain Concrete Floors DIY

- DIY Concrete Floor Grinding

Concrete Floor Cure Time: How Long Does it Take for Concrete Floors to Set?

Concrete floors are one of the most popular flooring materials in homes and businesses alike. They are durable, cost-effective, and can be customized to fit any design aesthetic. While the installation process may seem daunting, the curing time for concrete floors is relatively straightforward. Knowing how long it takes for a concrete floor to cure can help you plan your project accordingly and ensure that your floor is ready for use when you need it.

What is the Curing Process?

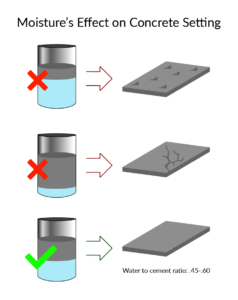

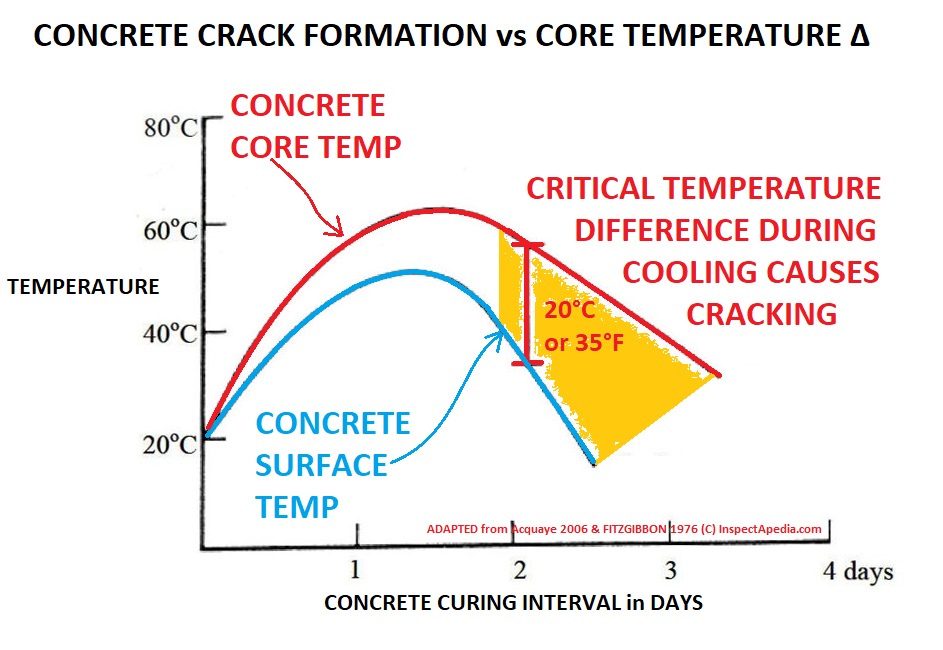

Concrete floors need to be cured before they can be used. The curing process occurs after the concrete has been poured, smoothed, and finished. It involves allowing the concrete to dry slowly over time in order to ensure that it sets properly and that its full strength is achieved. During this time, the water in the mix evaporates, causing the concrete to become harder and more durable. Proper curing also helps prevent cracking and spalling, which can weaken the concrete over time.

How Long Does it Take for Concrete Floors to Set?

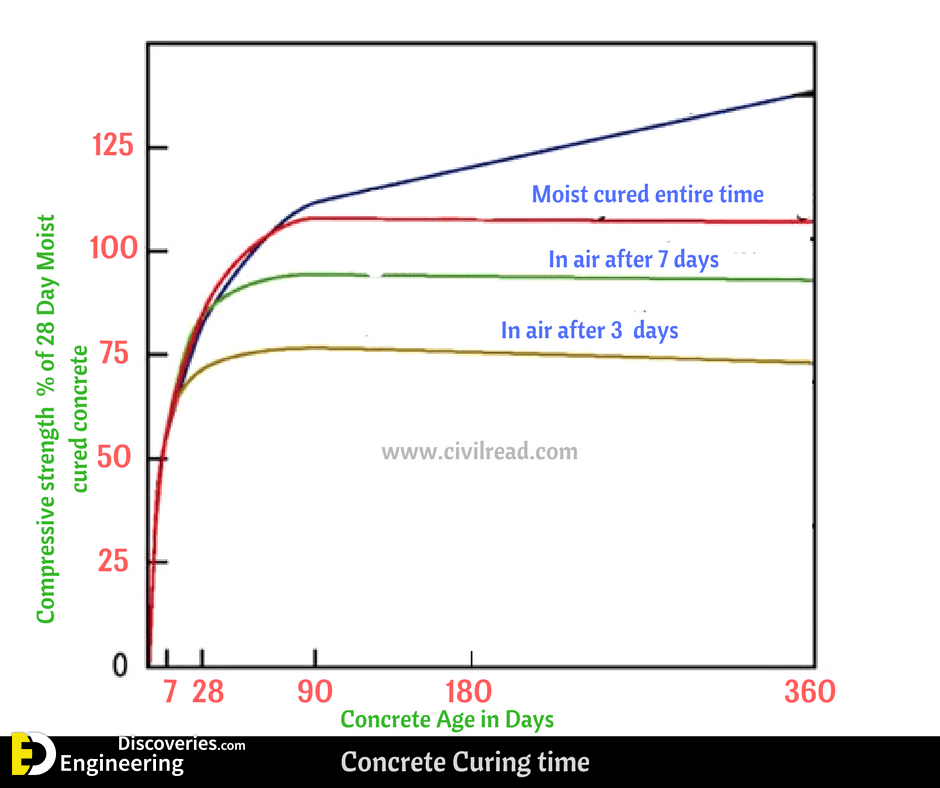

The amount of time it takes for a concrete floor to set depends on several factors, including the type of concrete used and the weather conditions during the curing process. Generally, however, it takes at least 28 days for a concrete floor to cure completely. This is because it takes at least 28 days for the water in the mix to fully evaporate and for the full strength of the concrete to be achieved.

It is important to note that while 28 days is generally considered long enough for a concrete floor to cure, this does not necessarily mean that you can use your new floor right away. In fact, you should wait at least two weeks before using your new concrete floor in order to allow it time to fully dry and harden. Waiting longer than two weeks will give your concrete floor an even stronger bond and make it more resistant to wear and tear over time.

What Factors Affect Cure Time?

The type of concrete used in your project will have a major impact on its cure time. For example, some types of ready-mix concretes are designed to set quickly and may only need 7-14 days of curing time. Other types of concretes may require longer curing times of up to 28 days or even longer depending on their composition. Additionally, different types of additives or admixtures may also affect the cure time of your concrete project.

In addition to the type of concrete used, other factors such as temperature and humidity will also affect how quickly your project cures. Generally speaking, warmer temperatures will cause faster evaporation of water from the mix and therefore a shorter curing time while cooler temperatures will slow down evaporation and increase curing times. Similarly, higher humidity levels will increase cure times while lower humidity levels will reduce them.

FAQs

Q: How can I tell when my concrete floor is cured?

A: The best way to tell when your concrete floor is cured is by assessing its hardness and durability. To do this, you can conduct a simple test by pressing your fingernail into the surface of the concrete – if your fingernail does not leave an indentation then it has likely cured sufficiently for use! Additionally, if you have chosen to seal your concrete floor then this will provide additional protection from wear and tear over time as well as making it easier to clean and maintain.

Q: Is there anything I can do to speed up the curing process?

A: There are a few things you can do to speed up the curing process for your concrete floors, such as ensuring that temperatures remain consistent throughout the curing period or adding accelerators or admixtures to your mix prior to pouring. However, it is important not to rush this process as doing so may lead to cracking or spalling down the line.

Q: What happens if I don’t cure my concrete correctly?

A: If you do not take proper care when curing your concrete floors then they may not achieve their full strength and durability potential over time. This could lead to cracking or spalling which may require costly repairs or even replacement down the line. Additionally, failing to adhere to proper curing procedures may void any warranties