Concrete floor floating is a technique used in construction and architecture to create a seamless and smooth finish on concrete floors. This method involves pouring a thin layer of concrete over an existing floor, allowing it to float and settle into place. The process of concrete floor floating is commonly used to improve the appearance and functionality of floors in residential and commercial spaces. By creating a level surface, it enhances the durability and longevity of the floor, making it suitable for high-traffic areas. Concrete floor floating allows for customization through decorative finishes such as staining or polishing. This technique has gained popularity due to its ability to transform ordinary concrete floors into aesthetically appealing and durable surfaces.

What is Concrete Floor Floating, and How Does it Work?

Concrete floor floating is a technique used in construction to create a smooth and level surface for the flooring material to be installed on. It involves pouring a thin layer of self-leveling compound over the existing concrete slab and using tools to spread and distribute the compound evenly. This process helps to eliminate any imperfections or unevenness in the concrete, resulting in a flat and flawless surface. The self-leveling compound comprises a combination of cement, sand, and other additives that allow it to flow and settle into place on its own. Once the compound is applied, it is left to dry and harden, creating a solid and stable base for the flooring material. This method is commonly used in residential and commercial projects to ensure a high-quality and durable floor finish.

Advantages of Using Concrete Floor Floating Techniques

Concrete floor floating techniques offer several advantages over traditional concrete floor installation methods. One of the main advantages is that it provides a smooth and level surface, eliminating the need for extensive floor leveling or grinding. This saves time and effort during installation and ensures a higher-quality finish.

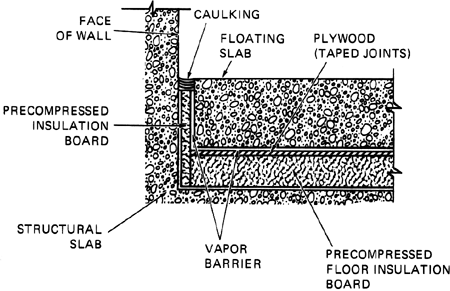

Another advantage is the increased durability and longevity of the concrete floor. Allowing the floor to “float” over a layer of insulation or underlayment reduces the risk of cracking or shifting due to temperature changes or moisture. This makes it ideal for areas with high foot traffic or heavy equipment.

Additionally, concrete floor floating techniques can help improve the energy efficiency of a building. The insulation layer or underlayment helps reduce heat loss, making the floor warmer and more comfortable to walk on. This can lead to cost savings on heating and cooling expenses in the long run.

Furthermore, floating concrete floors are also more versatile in design options. The underlayment layer provides a sound barrier, reducing noise transmission between floors. It also allows for installing various floor coverings such as tiles, hardwood, or carpets, allowing homeowners or businesses to choose the flooring material that best suits their needs and preferences.

Step-by-Step Guide to Achieving a Floating Concrete Floor

To achieve a floating concrete floor, follow these step-by-step instructions:

- Prepare the Subfloor: Ensure that the subfloor is clean, level, and free from debris. Remove any existing flooring or coverings.

- Install Vapor Barrier: Lay down a vapor barrier to prevent moisture from seeping into the concrete. This will help protect the floor from potential damage.

- Build the Formwork: Create a formwork using wooden boards or metal strips. This will define the shape and size of the floor. Make sure it is sturdy and properly aligned.

- Add Reinforcement: Place steel reinforcement bars or mesh within the formwork. This will provide added strength to the concrete floor.

- Mix and Pour Concrete: Prepare a concrete mix according to the manufacturer’s instructions. Pour the concrete into the formwork, ensuring it reaches all corners and edges. Use a screed or bull float to level the surface.

- Allow for Curing: Give the concrete sufficient time to cure and harden. This typically takes around 24 to 48 hours, but it may vary depending on the specific product and environmental conditions.

- Remove Formwork: Once the concrete has cured, carefully remove the formwork. Take caution not to damage the newly formed floor.

- Finishing Touches: Use a trowel to smooth out any imperfections on the surface. You may also consider applying a sealant or finishing coat to enhance the durability and appearance of the floor.

Common Mistakes to Avoid When Floating a Concrete Floor

When floating a concrete floor, several common mistakes should be avoided to ensure a successful and long-lasting result. One of the most common mistakes is not properly preparing the surface before floating. This includes removing existing coatings, cleaning the floor thoroughly, and repairing any cracks or damages. Failing to do so can result in poor adhesion and a compromised finish.

Another mistake to avoid is using the wrong type of float. Using a float specifically designed for concrete is essential to achieve the desired smoothness and levelness. Using a too soft or too hard float can lead to uneven surfaces and an unsatisfactory final product.

Inadequate mixing of the concrete mixture is another mistake to steer clear of. Properly mixing the concrete ensures that all the components are evenly distributed and have the right consistency. Failing to mix the concrete correctly can result in weak spots, uneven drying, and a lack of durability.

Lastly, rushing the floating process is a mistake that can have detrimental effects. Floating requires patience and attention to detail. It is important to allow the concrete to cure properly before applying the float. Attempting to float the concrete too early can cause ridges, unevenness, and a compromised finish.

Expert Tips for Maintaining and Extending the Lifespan of a Floating Concrete Floor

- Regular Cleaning: One of the key factors in maintaining a floating concrete floor is regular cleaning. Sweep or vacuum the floor to remove dirt, dust, or debris. Use a mild detergent and warm water to mop the floor, ensuring that you rinse thoroughly to remove any soap residue. Avoid harsh chemicals or abrasive cleaners, which can damage the floor’s surface.

- Avoid Heavy Impact: While floating concrete floors are durable, they are not completely immune to damage. Avoid dropping heavy objects or dragging furniture across the floor, which can cause cracks or chips. Place felt pads on the bottom of furniture legs to prevent scratches and minimize impact.

- Protect from Moisture: Moisture can seep into the concrete and weaken the floor’s structure. Use rugs or mats in areas prone to spills, such as kitchens or bathrooms. Wipe up any spills immediately to prevent water from seeping into the floor. Consider applying a water-resistant sealer to protect the surface from moisture damage.

- Regular Inspections: Periodically inspect the floor for any signs of damage or wear. Look for cracks, chips, or uneven areas and address them promptly. Small cracks can be repaired using a concrete filler, while larger damages may require professional assistance. Regular inspections can help identify issues early on and prevent them from worsening.

Final concrete layer of the floating floor. Download Scientific

How to construct a floating floor Insulation Kingspan Great

PU-D20 Concrete System u0026 DLP Floating Floor (A60) Floating Floor

Concrete Floating Floor System for Cinemas Cinema Acoustic Solutions

Pour a Floating Concrete Floor : 6 Steps (with Pictures

Floating floor Article about floating floor by The Free Dictionary

Floating Slabs – WADDELL ENGINEERING LTD

Advantages Of Floating Floors

Floating Wood Floor Over Concrete Slab – https://pickndecor.com

Related Posts:

- Applying Concrete Floor Paint

- Non Slip Concrete Floor Sealer

- How To Paint Concrete Garage Floor

- Outdoor Concrete Floor Ideas

- Concrete Floor Covering Ideas

- Cracks In Polished Concrete Floors

- Drylok Concrete Floor Paint Colors

- Polished Concrete Floor Thickness

- Residential Stained Concrete Floors

- Cheap Concrete Floor Finishes