Importance of Proper Floor Thickness

When it comes to polished concrete floors, proper thickness is crucial for ensuring durability, structural integrity, and overall performance. The right thickness can significantly impact the lifespan and functionality of your flooring, making it essential to get it right from the start.

- Structural Integrity The primary reason for ensuring proper floor thickness is to maintain structural integrity. A floor that is too thin may crack under heavy loads or due to normal wear and tear. Proper thickness ensures that the floor can withstand the stresses it will encounter over time.

- Load-Bearing Capacity The thickness of a concrete floor directly affects its load-bearing capacity. For areas that will experience heavy traffic or support heavy machinery, thicker concrete is necessary to prevent damage and maintain a safe, stable surface.

- Durability and Longevity Thicker concrete floors are generally more durable and have a longer lifespan. They are better able to resist damage from impacts, abrasions, and chemical spills, making them a practical choice for industrial and commercial settings.

- Thermal Mass and Energy Efficiency Properly thick concrete floors can act as thermal mass, helping to regulate indoor temperatures by absorbing, storing, and slowly releasing heat. This can enhance energy efficiency and contribute to a more comfortable indoor environment.

- Polishing Quality The thickness of the concrete also affects the quality of the polished finish. Thicker floors provide more material to work with, allowing for a more consistent and high-quality polish. Thinner floors may not polish as well, leading to an uneven appearance.

- Cost Considerations While thicker floors may have higher initial costs due to the additional materials and labor required, they often result in lower maintenance and repair costs over time. Investing in the proper thickness from the beginning can be more cost-effective in the long run.

Factors Determining Concrete Floor Thickness

Several factors must be considered when determining the appropriate thickness for a polished concrete floor. These factors help ensure the floor will meet the specific needs and demands of its intended use.

Intended Use of the Space The primary use of the space is a key factor in determining floor thickness. Residential areas typically require thinner floors compared to industrial or commercial spaces, which may need to support heavy equipment or high traffic.

Load Requirements The expected load on the floor is crucial. For example, floors in warehouses or garages that need to support heavy vehicles or machinery will require greater thickness to prevent cracking and other structural issues.

Subfloor Conditions The condition and type of subfloor can influence the required thickness. A stable, well-prepared subfloor can support thinner concrete, while an unstable or uneven subfloor may necessitate a thicker pour to ensure stability and prevent future issues.

Climate and Environmental Factors Environmental conditions such as temperature fluctuations, humidity, and potential exposure to chemicals can affect concrete performance. In areas prone to extreme conditions, thicker floors can provide additional durability and resistance to damage.

Polishing Requirements The level of polish desired can impact thickness decisions. Floors that require a high-gloss, mirror-like finish may need to be thicker to ensure sufficient material for grinding and polishing without exposing aggregate or flaws.

Building Codes and Regulations Local building codes and regulations often specify minimum thickness requirements for concrete floors. Compliance with these standards is essential for safety, structural integrity, and legal reasons.

Standard Thickness for Different Applications

The required thickness for polished concrete floors varies depending on the application and use of the space. Here are some standard thickness recommendations for different settings.

Residential Floors For residential applications such as living rooms, kitchens, and basements, a thickness of 3 to 4 inches is typically sufficient. These areas generally experience light to moderate foot traffic and minimal heavy loads.

Commercial Floors In commercial settings like retail stores, offices, and restaurants, a thicker floor of 4 to 6 inches is recommended. These areas see higher foot traffic and may need to support heavier furnishings and equipment.

Industrial Floors Industrial environments such as factories, warehouses, and manufacturing plants require significantly thicker floors, often ranging from 6 to 8 inches. These floors need to withstand heavy machinery, forklifts, and continuous use.

Garage Floors Garage floors, whether residential or commercial, need to support the weight of vehicles and potentially heavy equipment. A thickness of 4 to 6 inches is generally recommended for these applications.

Driveways and Outdoor Areas For outdoor areas like driveways, patios, and walkways, a thickness of 4 to 5 inches is typically adequate. These areas need to endure the weight of vehicles and exposure to the elements.

Specialized Applications Specialized applications such as airport hangars, fire stations, and other high-stress environments may require floors thicker than 8 inches. These floors must support extremely heavy loads and withstand intense use.

Pros and Cons of Thicker Concrete Floors

While thicker concrete floors offer several benefits, they also come with some drawbacks. Here’s a balanced look at the pros and cons of opting for thicker concrete floors.

Pros: Increased Durability Thicker concrete floors are more durable and can withstand greater stress, making them ideal for high-traffic and heavy-load areas. They are less likely to crack or develop other structural issues over time.

Pros: Enhanced Load-Bearing Capacity With increased thickness comes an improved load-bearing capacity. This makes thicker floors suitable for industrial settings, garages, and other environments where heavy machinery and vehicles are present.

Pros: Better Thermal Mass Thicker concrete floors have better thermal mass properties, which can help regulate indoor temperatures. This can lead to improved energy efficiency and a more comfortable environment, especially in climates with significant temperature fluctuations.

Pros: Superior Polishing Results The additional material in thicker floors allows for a higher-quality polish. Thicker floors can achieve a more consistent and aesthetically pleasing finish, making them a better choice for spaces where appearance is important.

Cons: Higher Initial Cost One of the main drawbacks of thicker concrete floors is the higher initial cost. The increased material and labor required can make the upfront investment significant. However, this can be offset by lower maintenance and repair costs over time.

Cons: Longer Installation Time Thicker floors require more time to pour, cure, and polish. This can extend the overall timeline of a project, which might be a consideration for time-sensitive renovations or constructions.

Tips for Achieving Optimal Floor Thickness

Achieving the optimal thickness for your polished concrete floor involves careful planning and execution. Here are some tips to help you get the best results.

Consult with Professionals Working with experienced professionals is crucial. They can provide expert advice on the appropriate thickness based on your specific needs and the conditions of your space. Professional assessment ensures that all factors are considered.

Conduct a Thorough Assessment Before starting, conduct a thorough assessment of the subfloor and surrounding environment. Identify any potential issues such as moisture, instability, or uneven surfaces that need to be addressed before pouring the concrete.

Use Quality Materials Invest in high-quality concrete and additives. Using superior materials can enhance the strength and durability of the floor, ensuring it meets the required performance standards even with a specified thickness.

Ensure Proper Mixing and Pouring Proper mixing and pouring techniques are essential for achieving a consistent thickness. Follow best practices for mixing the concrete to the correct consistency and ensure even pouring to avoid weak spots or variations in thickness.

Allow Sufficient Curing Time Curing is a critical step in the process. Allow sufficient time for the concrete to cure fully before proceeding with polishing. Proper curing enhances the strength and longevity of the floor, ensuring it performs well under stress.

Plan for Future Use Consider potential future uses of the space when determining thickness. If there’s a chance the area might see increased traffic or heavier loads in the future, it might be wise to opt for a thicker floor initially to avoid complications later.

CE Center –

CE Center –

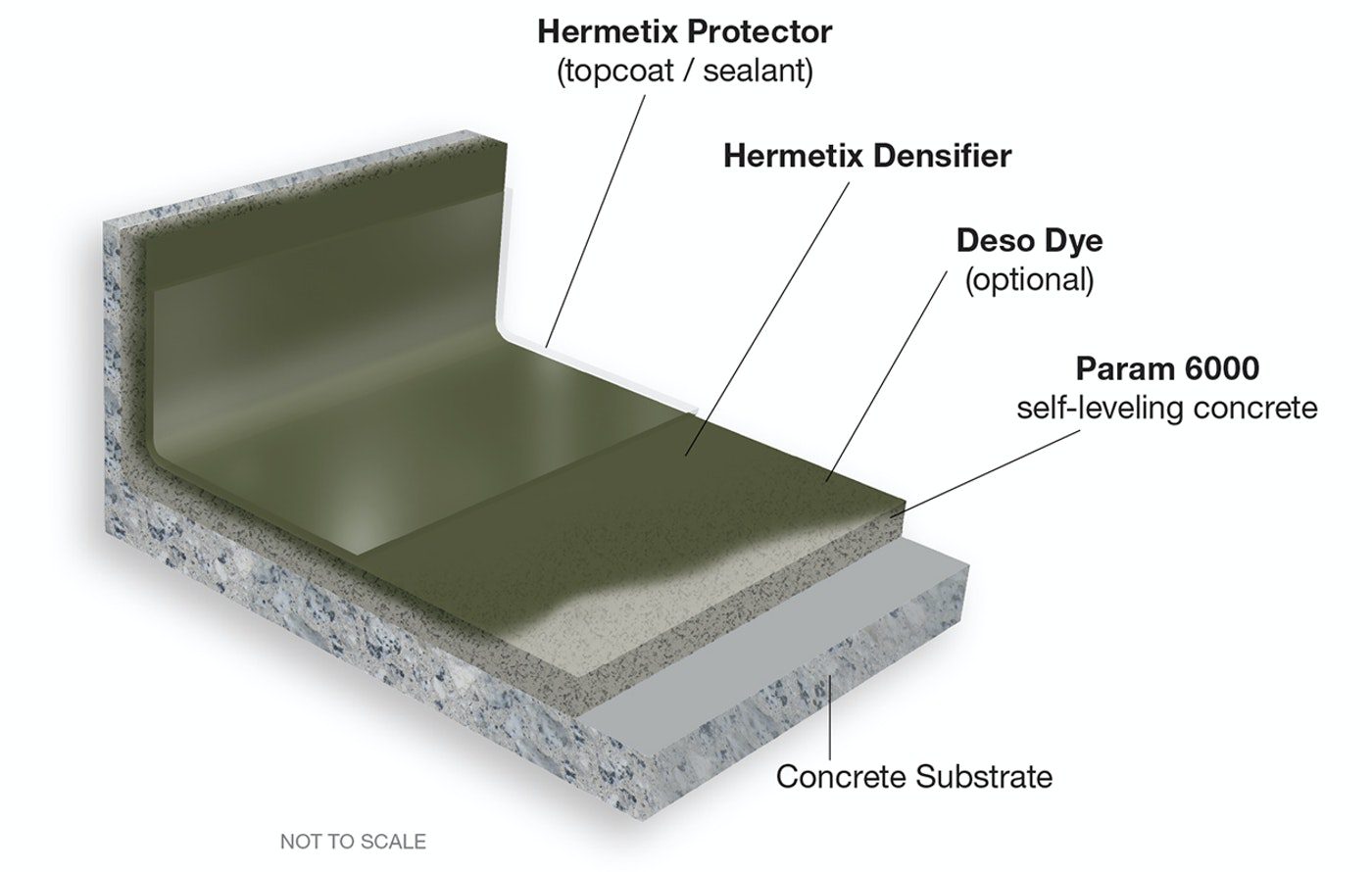

Polished Concrete Flooring System Duraamen

The Different Types Of Polished Concrete Floors

Polished Topping / Overlay – Polished Concrete, Epoxy Resin

Micro Cement Flooring Microcement, Cement floor, Concrete floors

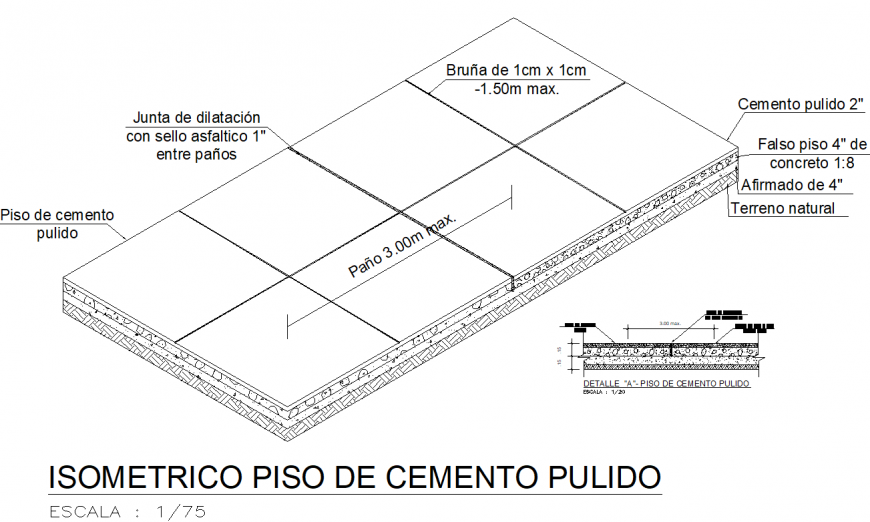

Polished concrete floor isometric autocad file – Cadbull

CE Center –

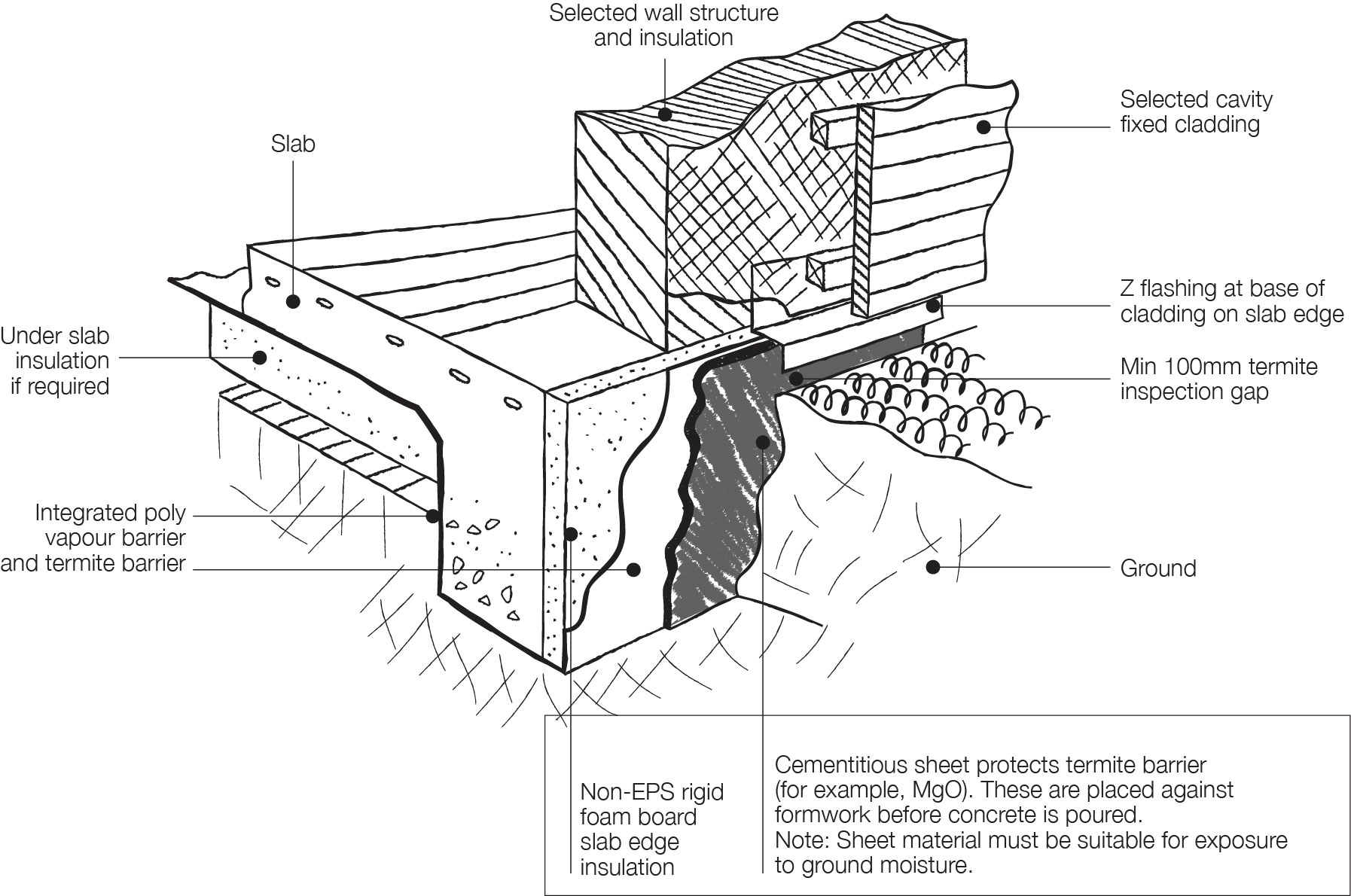

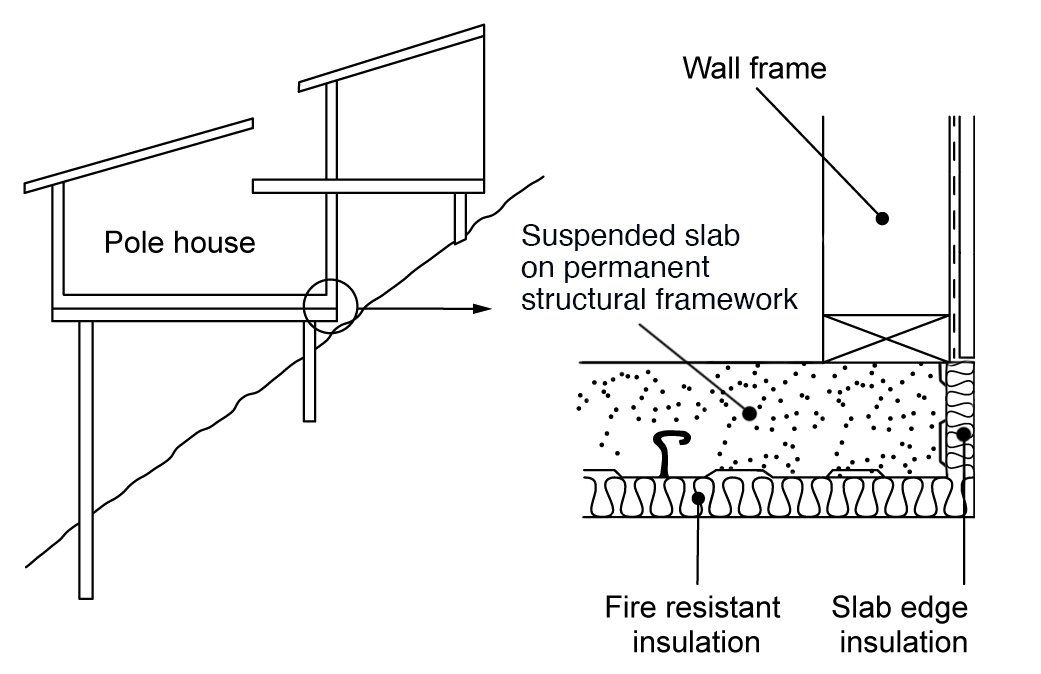

Concrete slab floors YourHome

Concrete slab floors YourHome

Related Posts:

- Applying Concrete Floor Paint

- Non Slip Concrete Floor Sealer

- How To Paint Concrete Garage Floor

- Outdoor Concrete Floor Ideas

- Concrete Floor Covering Ideas

- Cracks In Polished Concrete Floors

- Drylok Concrete Floor Paint Colors

- Polished Concrete Floor Thickness

- Residential Stained Concrete Floors

- Cheap Concrete Floor Finishes