Overview of Concrete Floor Joist System

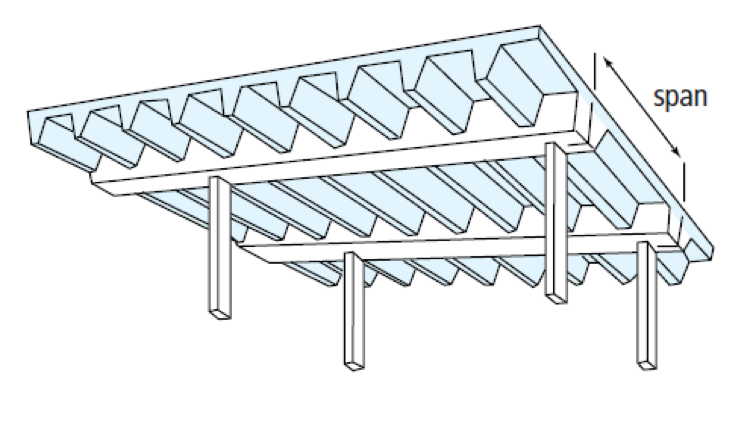

The concrete floor joist system is a structural component used in the construction of floors in buildings. It is designed to provide support and distribute the weight of the structure to the foundation. This system is commonly used in commercial, industrial, and residential buildings. The main purpose of the concrete floor joist system is to create a solid and durable flooring structure that can withstand heavy loads and resist various external forces. It is typically composed of a series of precast concrete joists, which are placed parallel to each other and supported by load-bearing walls or beams.

One of the key advantages of the concrete floor joist system is its strength and stability. The use of concrete as the primary material ensures that the floor can support heavy loads without sagging or cracking. Additionally, the system can effectively distribute the weight of the structure to the foundation, preventing any localized stress points. Another benefit of the concrete floor joist system is its fire resistance. Concrete has inherent fire-resistant properties, which can help slow down the spread of fire and provide additional time for evacuation or firefighting efforts. This makes it a preferred choice for buildings that require enhanced fire safety measures.

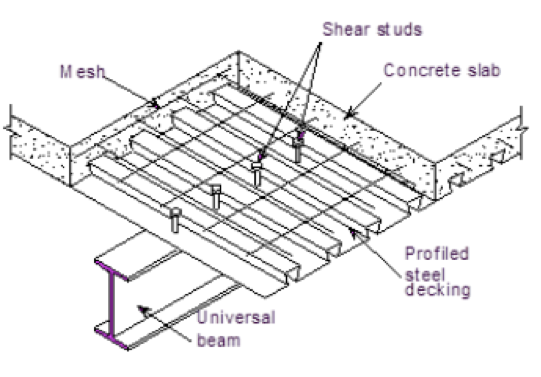

The installation process of the concrete floor joist system involves placing the precast concrete joists at regular intervals and securing them to the load-bearing walls or beams. The joists are then reinforced with steel bars to further enhance their strength and durability. Finally, a layer of concrete is poured over the joists to create a seamless and level floor surface. In essence, the concrete floor joist system is a reliable and efficient method for constructing floors in various types of buildings. Its strength, stability, and fire resistance make it a popular choice among builders and architects. The installation process is straightforward, and the resulting floor structure is capable of withstanding heavy loads and providing long-lasting performance.

Advantages of Using Concrete Floor Joist System

Durability: Concrete floor joist systems are known for their exceptional durability. Concrete is a strong and long-lasting material that can withstand heavy loads and resist damage from moisture, pests, and fire. This makes it ideal for use in areas with high foot traffic or where there is a need for a sturdy foundation.

Stability: The use of a concrete floor joist system provides enhanced stability to the structure. Concrete is a rigid material that can effectively distribute the load evenly across the entire floor area, minimizing the risk of sagging or uneven settling. This stability is crucial in ensuring the structural integrity of the building and preventing potential damage.

Design flexibility: Concrete floor joist systems offer a wide range of design possibilities. They can be customized to meet specific architectural requirements, allowing for various shapes and sizes to be incorporated into the design. This flexibility enables architects and builders to create unique and aesthetically pleasing structures.

Sound insulation: Concrete is an excellent material for sound insulation. The dense nature of concrete helps to reduce the transmission of sound between floors, providing a quieter and more comfortable living or working environment. This is particularly beneficial in multi-story buildings or spaces where noise reduction is important, such as hospitals, schools, or residential areas.

Energy efficiency: Concrete floor joist systems have excellent thermal properties, which contribute to energy efficiency. Concrete acts as a thermal mass, absorbing and storing heat during the day and releasing it slowly at night, helping to maintain a comfortable temperature indoors. This reduces the reliance on heating and cooling systems, leading to lower energy consumption and cost savings in the long run.

Sustainability: Concrete is a sustainable construction material that can contribute to a greener and more environmentally friendly building. It is made from abundant natural resources, such as limestone and clay, and can be produced locally, reducing transportation emissions. Additionally, concrete has a long lifespan, which means fewer resources are needed for maintenance or replacement.

Overall, the use of a concrete floor joist system offers numerous advantages, including durability, stability, design flexibility, sound insulation, energy efficiency, and sustainability. These benefits make it a popular choice for various types of construction projects, from residential homes to commercial buildings.

Installation Process of Concrete Floor Joist System

The installation process of a concrete floor joist system involves several steps to ensure a sturdy and durable foundation.

Preparation: Before starting the installation, the area must be prepared accordingly. This includes clearing the site of any debris or obstacles that may hinder the installation process. The ground should be leveled and compacted to provide a stable base for the concrete floor joist system.

Layout and marking: The layout of the concrete floor joist system is crucial for proper installation. Using the architectural plans, the location of each joist and the spacing between them are marked on the ground. This ensures accurate placement and alignment during the installation process.

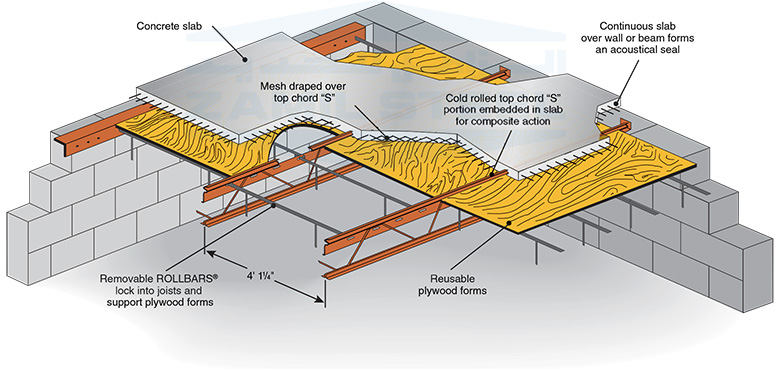

Formwork construction: Formwork is constructed to provide a mold or framework for the concrete to be poured into. This typically involves building temporary structures using plywood or metal panels that outline the shape and dimensions of the floor joists. The formwork must be secure and properly aligned to ensure the concrete is poured evenly and accurately.

Reinforcement placement: Depending on the design and load requirements, reinforcement bars or mesh may be placed within the formwork. These reinforcements add strength and stability to the concrete floor joist system, allowing it to bear heavy loads. The reinforcement is carefully positioned according to the architectural plans and secured within the formwork.

Concrete pouring: Once the formwork and reinforcement are in place, the concrete is poured into the designated area. It is essential to use high-quality concrete and ensure proper mixing to achieve the desired strength and durability. The concrete is poured evenly, filling the entire formwork and covering the reinforcement completely.

Finishing and curing: After the concrete is poured, it is leveled and finished using trowels or other tools to achieve a smooth and even surface. Curing is then carried out to allow the concrete to strengthen and harden over time. This typically involves covering the concrete with a curing compound or moist curing it to prevent premature drying and cracking.

Removal of formwork: Once the concrete has cured sufficiently, the formwork is carefully removed. This should be done gradually and with caution to avoid any damage to the newly installed concrete floor joist system.

Maintenance of Concrete Floor Joist System

The maintenance of a concrete floor joist system is essential to ensure its longevity and structural integrity. Regular maintenance practices can help identify any potential issues and address them promptly, preventing further damage and costly repairs. Here are some key maintenance tasks for a concrete floor joist system:

Visual Inspections: Regularly inspect the concrete floor joists for any signs of cracks, spalling, or deterioration. These visual inspections can help identify early warning signs of structural problems and allow for timely repairs.

Cleaning: Keep the concrete floor joists clean by removing any debris, dirt, or chemicals that may accumulate over time. Regular cleaning helps prevent the buildup of corrosive substances that can affect the durability and strength of the concrete.

Waterproofing: Apply a waterproofing sealant to the concrete floor joists to protect them from moisture penetration. Moisture can weaken the concrete and lead to structural issues such as corrosion of reinforcement bars or the growth of mold and mildew.

Repairs: Promptly address any identified issues, such as cracks or spalling, through proper repair techniques. Follow recommended repair methods and use appropriate materials to ensure the structural integrity of the concrete floor joist system.

Load Limitations: Ensure that the concrete floor joist system is not subjected to excessive loads beyond its design capacity. Regularly assess the weight-bearing capacity of the joists and avoid overloading them to prevent structural failures.

STRUCTURAL CONCRETE FLOOR SYSTEMS FOR ARCHITECTS (IN ARABIC )

One-Way Concrete Band Slab u0026 Joist Floor System Dimensions

Types of Cast-in-Place Concrete Roof and Floor Systems

One-Way Concrete Joist Slab Floor System Dimensions u0026 Drawings

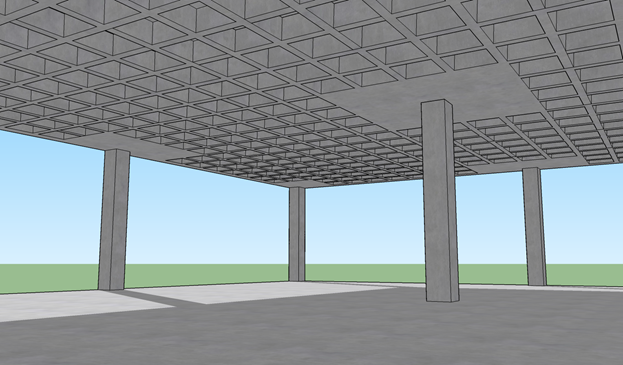

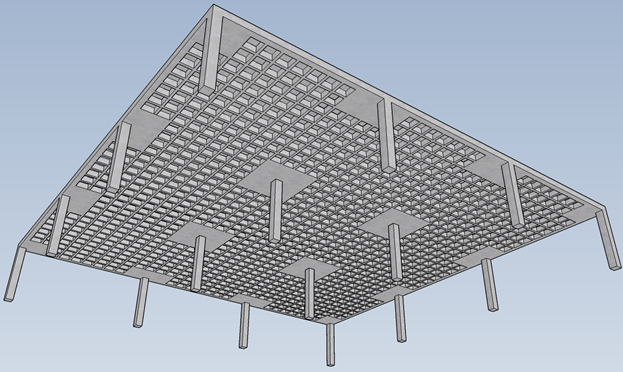

Two-Way-Joist-Concrete Slab-Floor-(Waffle-Slab)-System-Analysis

Two-Way-Joist-Concrete Slab-Floor-(Waffle-Slab)-System-Analysis

HAMBRO D500 Composite Floor System

Aerial Floor System Product & Aerial Precast Concrete

Guidelines for a one-way concrete flooring system Brewer Smith

Related Posts: