Concrete Floor Screed Specification: A Comprehensive Guide

Concrete floor screed is a versatile material used in various construction projects to provide a smooth and level surface for the flooring. It is typically applied on top of a concrete base or subfloor to create a durable and functional surface. However, in order to ensure the successful installation of concrete floor screed, it is essential to have a well-defined specification.

- Understanding the Basics: Concrete floor screed is a crucial element in construction projects, providing a smooth and level surface for flooring. It is applied over a concrete base, enhancing durability and functionality.

- The Significance of Specification: To ensure a successful installation, a well-defined specification is paramount. This document outlines requirements, materials, and methods, serving as a guide for contractors, architects, and engineers.

- Crucial Mix Design: The mix design is a pivotal aspect of the specification, detailing proportions of cement, aggregates, and water. This ensures that the screed attains the necessary strength, workability, and durability.

- Base or Subfloor Preparation: The specification covers the preparation of the base or subfloor, emphasizing essential steps such as cleaning, leveling, and priming. These steps are crucial for proper adhesion of the screed to the substrate.

- Application and Finishing Techniques: Detailed guidelines in the specification address application and finishing techniques. It specifies screed thickness, application methods (hand or pump), and the required tools and equipment for a seamless installation.

- Curing Time and Drying Time: Factors like curing time and drying time are explicitly addressed in the specification. These parameters are critical in achieving the desired strength, durability, and overall performance of the screed.

- Additives and Admixtures: The specification delves into the use of additives or admixtures, highlighting their importance in enhancing specific properties of the screed. This ensures a tailored approach to meet project requirements.

- Ensuring Consistency and Quality: A robust concrete floor screed specification ensures that all stakeholders are aligned on requirements and expectations. This alignment minimizes the risk of potential issues or disputes, allowing contractors to consistently deliver high-quality screed installations that meet project needs.

Factors to Consider in Concrete Floor Screed Specification

When specifying concrete floor screed, there are several important factors that need to be taken into consideration to ensure the desired outcome. These factors include:

- Type of screed: There are different types of screeds available, such as traditional sand and cement screed, self-levelling screed, and polymer-modified screed. The choice of screed will depend on factors such as the purpose of the floor, the expected foot traffic, and the substrate condition.

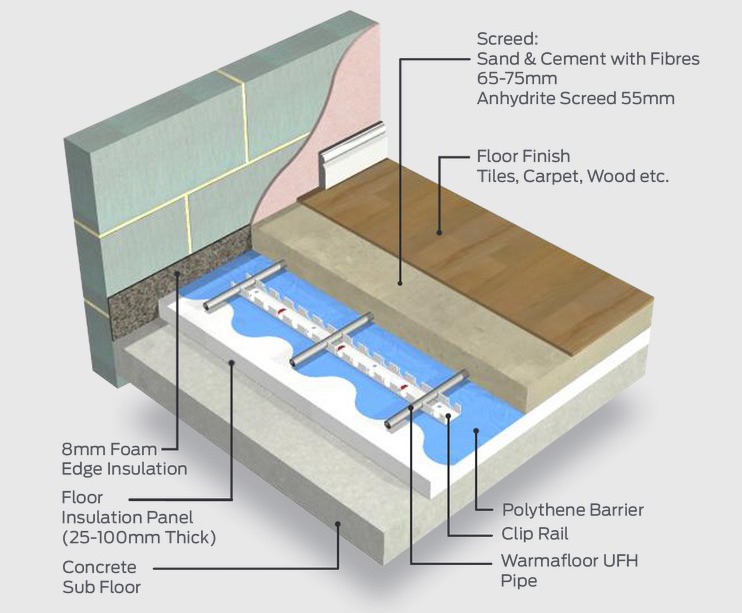

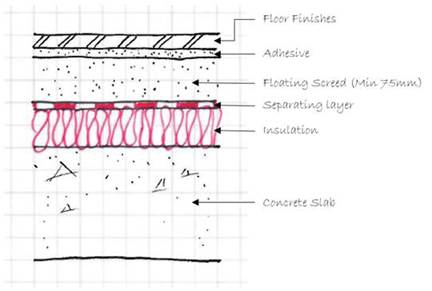

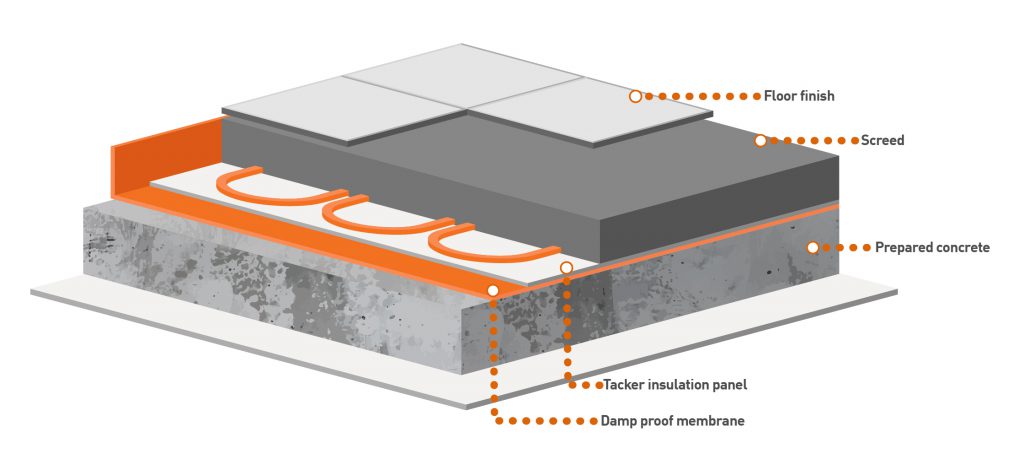

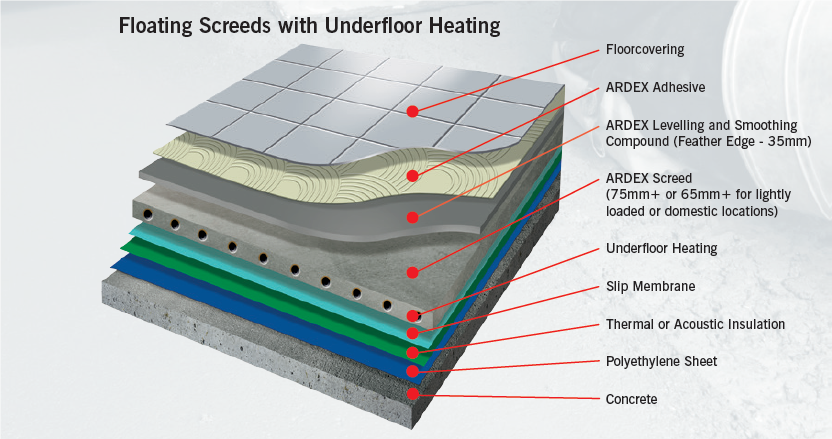

- Thickness: The thickness of the screed is an important consideration as it can affect the strength and durability of the floor. The required thickness will depend on factors such as the load-bearing capacity of the substrate, the intended use of the floor, and any specific requirements for insulation or underfloor heating.

- Mix design: The mix design of the screed is crucial in achieving the desired performance. Factors to consider include the type and quality of the aggregates, the cement content, the water-cement ratio, and any additives or admixtures that may be required. The mix design should be in accordance with relevant standards and specifications.

- Drying time: The drying time of the screed is an important consideration, especially if there are time constraints or if the floor needs to be used soon after installation. Factors that can influence drying time include the type and thickness of the screed, the environmental conditions, and any measures taken to accelerate drying, such as the use of drying agents or underfloor heating.

- Surface finish: The desired surface finish will also impact the specification of the screed. Factors to consider include the levelness and smoothness required, any specific aesthetic or functional requirements, and the need for additional treatments such as sealing or polishing.

- Compatibility with other flooring materials: If the concrete floor screed is intended to be covered with another type of flooring material, such as tiles or carpet, it is important to ensure compatibility between the screed and the chosen material. Factors to consider include the adhesive or fixing method, any specific preparation or priming requirements, and any limitations or recommendations from the manufacturer of the flooring material.

Types of Concrete Floor Screed and their Specifications

There are various types of concrete floor screed available in the market, each with its own set of specifications. These types include:

- Traditional Screed: Traditional screed is a sand and cement mixture laid in a semi-dry state. It is commonly used in domestic and commercial applications. The thickness of traditional screed typically ranges from 25mm to 100mm. The drying time for traditional screed is around one day per millimeter of thickness.

- Liquid Screed: Liquid screed is a self-leveling compound that is poured onto the floor surface. It is made up of a combination of cement, sand, and water, along with additives to enhance its flowability. Liquid screed is known for its fast drying time, typically ranging from 24 to 48 hours. It is ideal for underfloor heating systems due to its excellent thermal conductivity.

- Polymer Screed: Polymer screed is a type of screed that incorporates polymers, such as latex or acrylic, in the mix. These polymers improve the screed’s durability and flexibility, making it suitable for areas that are prone to heavy traffic or potential movement. Polymer screed can also be applied thinly, with typical thicknesses ranging from 3mm to 50mm.

- Fiber-Reinforced Screed: Fiber-reinforced screed contains fibers, such as polypropylene or steel, which enhance its strength and resistance to cracking. This type of screed is commonly used in industrial or commercial settings where heavy loads or high impact resistance is required. The thickness of fiber-reinforced screed can vary based on the specific project requirements.

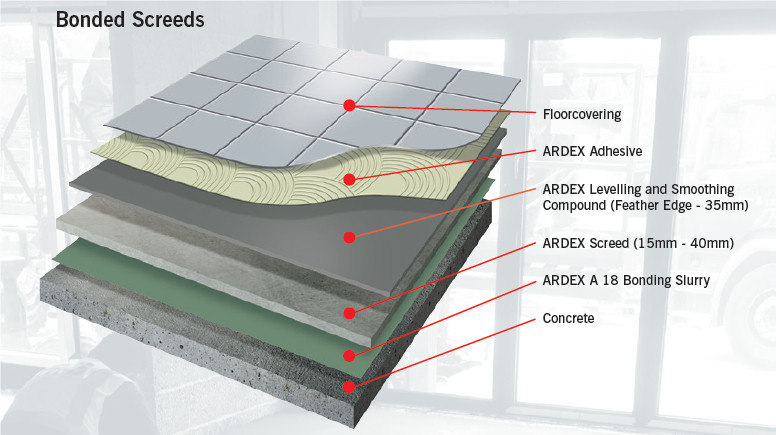

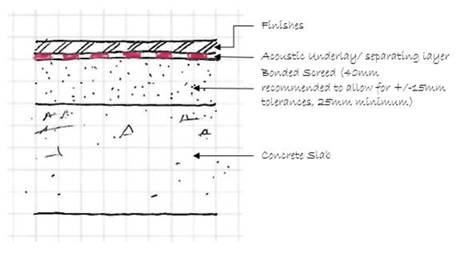

- Bonded Screed: Bonded screed is applied directly onto a prepared base, such as concrete or an existing floor surface. It is commonly used in areas with a stable substrate, such as ground floors or where the existing floor is in good condition. The thickness of bonded screed can vary depending on the specific application, but it is typically around 25mm to 40mm.

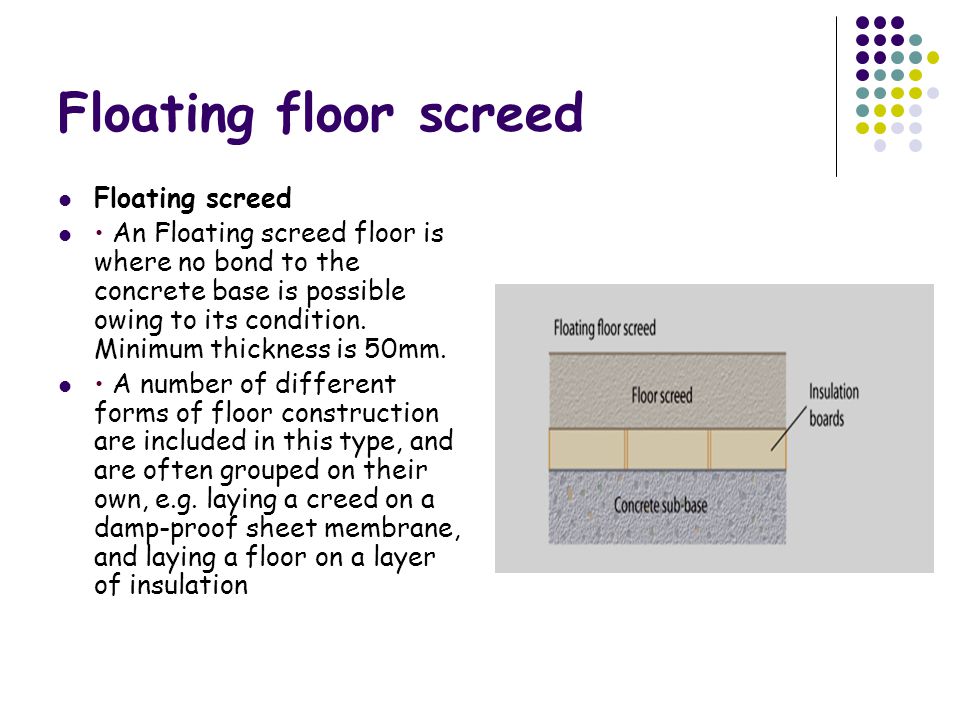

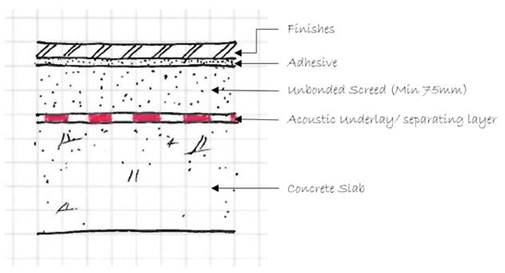

- Unbonded Screed: Unbonded screed is applied over a damp-proof membrane, which separates it from the base. This type of screed is commonly used in situations where the substrate is not suitable for direct application, such as suspended floors or where there is a risk of moisture penetration.

Best Practices for Implementing Concrete Floor Screed Specification

Clear and Detailed Specifications:

When implementing concrete floor screed specifications, it is crucial to have clear and detailed guidelines. The specifications should outline the desired characteristics, such as the thickness, composition, curing time, and finish of the screed. This ensures that all parties involved, including contractors and suppliers, have a clear understanding of the project requirements.

Quality Control Measures:

To ensure the successful implementation of concrete floor screed specifications, it is essential to establish quality control measures. This involves regular inspections, testing, and monitoring of the screed during the installation process. Quality control measures help identify any deviations from the specifications and allow for timely corrective actions.

Proper Surface Preparation:

Before applying the screed, proper surface preparation is crucial. This includes removing any loose debris, dirt, or contaminants from the substrate. Additionally, the surface should be adequately leveled and free from any cracks or imperfections. Adequate surface preparation ensures better adhesion and overall performance of the screed.

Accurate Mixing and Proportioning:

The mixing and proportioning of the screed materials should be accurate to achieve the desired consistency and strength. It is important to follow the manufacturer’s guidelines and use the correct proportions of cement, sand, additives, and water. Proper mixing ensures a homogenous mix, reducing the risk of weak spots or uneven curing.

Adequate Curing Time:

Proper curing is essential for the screed to achieve its full strength and durability. The specifications should include the recommended curing time, which typically involves keeping the screed moist and protected from excessive drying. Adequate curing ensures that the screed develops the desired properties and minimizes the risk of cracking or shrinkage.

Compliance with Industry Standards:

When implementing concrete floor screed specifications, it is important to ensure compliance with relevant industry standards and codes. These standards provide guidelines for best practices, material selection, installation techniques, and quality control. Adhering to industry standards ensures that the screed meets the required performance and safety criteria.

Regular Communication and Collaboration:

Effective communication and collaboration between all parties involved in the implementation process are crucial for successful results. This includes clear communication of expectations, regular progress meetings, and addressing any concerns or issues promptly. Collaboration helps ensure that all stakeholders are aligned, leading to a smoother and more efficient implementation of the concrete floor screed specifications.

A BSBG guide to floor screeds Brewer Smith Brewer Group

A BSBG guide to floor screeds Brewer Smith Brewer Group

What is Screed? EasyMix Concrete UK Ltd

Types of Screed Bonded Screed Unbonded Screed Floating Screed

The importance of floor screed design – part 1 This Is Construction

Floor Screeding Lesson no ppt video online download

Types of Floor Screed – London Flow Screed

Some information about Floor Screed Constructioncost

Floor Screed Thickness – What Are The Minimum u0026 Maximum Depths?

Related Posts:

.jpeg)