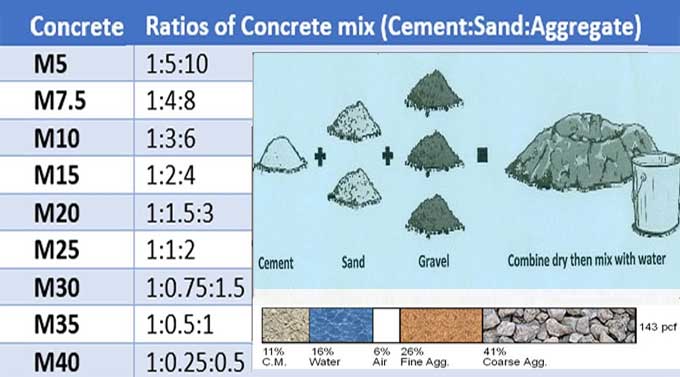

Concrete floor slab mix ratio refers to the proportion of ingredients used to create a concrete mixture suitable for pouring and forming a floor slab. The mix ratio typically includes a combination of cement, aggregate (such as sand or gravel), and water, with optional additives such as admixtures or fibers to enhance performance and durability. The mix ratio is crucial for achieving the desired strength, durability, and workability of the concrete floor slab, as well as ensuring proper curing and long-term performance.

Images about Concrete Floor Slab Mix Ratio

Concrete Floor Slab Mix Ratio

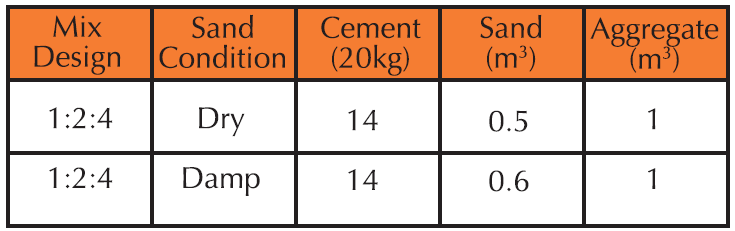

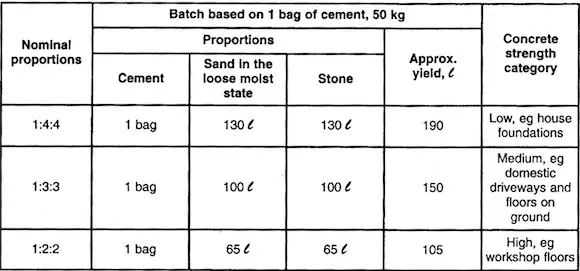

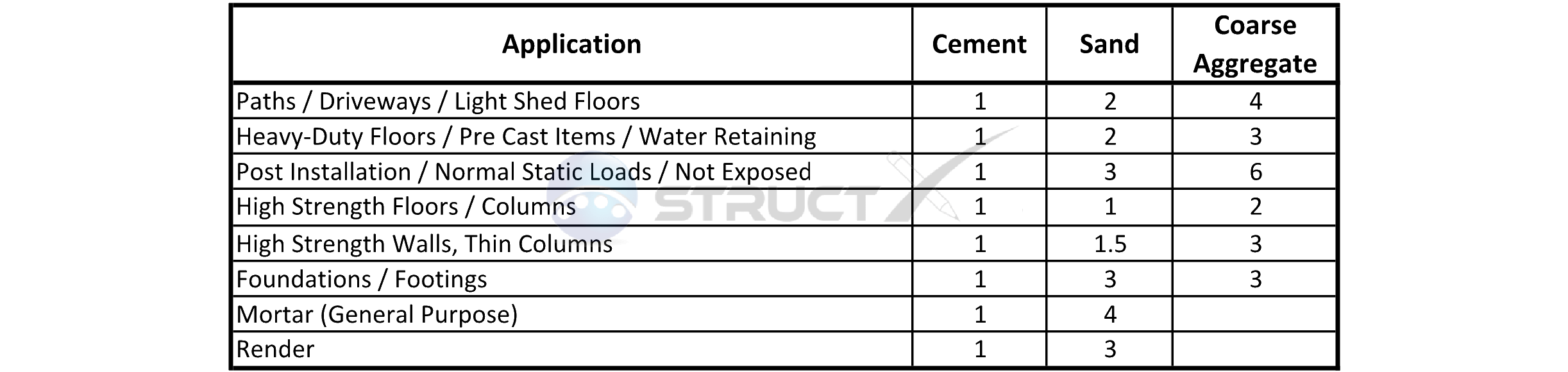

The most common mix ratio for concrete floor slabs is typically expressed as a ratio of parts by volume or weight. For example, a typical mix ratio for a standard concrete floor slab might be 1 part cement, 2 parts sand, 3 parts gravel, and enough water to achieve the desired consistency. However, mix ratios can vary depending on factors such as the specific requirements of the project, the type of cement and aggregates used, and environmental conditions such as temperature and humidity.

In addition to the basic ingredients of cement, sand, and gravel, concrete floor slab mix ratios may also include additives such as plasticizers, accelerators, or fibers to enhance specific properties of the concrete. For example, plasticizers can improve workability and reduce water content, while accelerators can speed up the curing process and increase early strength development. Fibers such as steel, synthetic, or natural fibers can improve the tensile strength and crack resistance of the concrete, reducing the likelihood of cracking and improving long-term durability.

Properly proportioned mix ratios are essential for achieving the desired performance and durability of concrete floor slabs. Mixing concrete ingredients in the correct proportions ensures that the concrete achieves the necessary strength, workability, and durability for its intended use. It’s essential to follow industry standards and guidelines for concrete mix ratios to ensure the structural integrity and long-term performance of concrete floor slabs, as well as to comply with building codes and regulations. Additionally, proper curing and finishing techniques are crucial for achieving optimal results and maximizing the lifespan of concrete floor slabs.

HOME DZINE Home DIY The right mix for concrete

How to calculate materials for different-ratio concrete

What is the best concrete mix ratio for concrete structure – Civil Sir

Correct Ratios for Concrete Mixes Concrete mix design, Concrete

Concrete Mix Ratio What Is Concrete Mix Ratio

Concrete Mix Ratio – Types, Grades & Designs

Concrete Mix Ratios – Cement, Sand, Aggregate and Water

Concrete mix ratio Table concrete grade types – Civil Sir

Concrete Mix Ratios (Cement, Sand, Gravel)

Best concrete mix ratio for roof slab, beam and column – Civil Sir

Related Posts:

- Best Exterior Concrete Floor Paint

- How To Skim Coat Concrete Floor

- Concrete Floor Resurfacing Cost

- DIY Concrete Floor Paint

- Laying A Concrete Floor For A Shed

- Concrete Floor Finish Standards

- Painting A Concrete Floor To Look Like Stone

- Concrete Floor Insulation Details

- Concrete Floor Radiant Heating

- Suspended Concrete Floor Slab Specifications

Concrete Floor Slab Mix Ratio

Making the Right Choice for Your Project

When it comes to laying down a concrete floor slab, getting the mix ratio of the concrete right is vital. If your ratio is wrong, you can end up with a weak slab that is prone to cracking or worse, one that does not even last long enough for you to finish the job. So, what should you consider when choosing the right mix ratio for your concrete floor slab? Let’s take a look.

What is the Ideal Concrete Mix Ratio?

The ideal concrete mix ratio for a concrete floor slab is one part cement to two parts aggregate and four parts sand. This ratio is designed to provide the best balance between strength and workability. It also ensures that enough water is added to the mix to allow it to set properly. Using this ratio in conjunction with other additives and admixtures, such as plasticizers and accelerators, can help to create a durable concrete floor slab that will last for many years.

Why is the Mix Ratio Important?

The mix ratio of a concrete floor slab is important because it affects both the strength and durability of the finished product. If too much water or not enough aggregate or sand is used, the concrete will be weaker and more prone to cracking. On the other hand, if too much aggregate or sand is used, then the slab will be too hard and difficult to work with. Therefore, it is important to get the mix ratio right to ensure that your floor slab will be strong and durable enough for its intended purpose.

How Can You Get the Right Mix Ratio?

The best way to get the right mix ratio for your concrete floor slab is by using a ready-mix concrete supplier. These suppliers are experienced in creating custom concrete mixes for specific projects and can ensure that your mix has the correct proportions of cement, aggregate, and sand. Additionally, they can also add any additional additives or admixtures that may be required for your project. Ready-mix suppliers can also provide advice on best practices for working with concrete, such as curing times and finishing techniques.

What Other Factors Should I Consider When Choosing a Concrete Mix Ratio?

In addition to getting the right mix ratio from a ready-mix supplier, there are several other factors that you should consider when choosing a concrete mix ratio for your project. First, you should take into account any environmental factors that may affect your project, such as extreme temperatures or high levels of humidity. Additionally, you should also consider any special requirements that you may have for your project such as specific compressive strengths or other performance characteristics. Finally, you should also consider any aesthetic requirements that you may have such as coloration or texturing of the finished product.

What is the ideal mix ratio for a concrete floor slab?

The ideal mix ratio for a concrete floor slab is one part cement to two parts aggregate and four parts sand. This ratio provides the best balance between strength and workability and ensures that enough water is added to allow it to set properly.

Why is it important to get the mix ratio right?

The mix ratio of a concrete floor slab affects both its strength and durability. If too much water or not enough aggregate or sand is used, then the slab will be weak or prone to cracking. Conversely, if too much aggregate or sand is used then it will be too hard and difficult to work with. Therefore, it is important to get the mix ratio right to ensure that your floor slab will be strong and durable enough for its intended purpose.

How can I get the right mix ratio?

The best way to get the right mix ratio for your project is by using a ready-mix concrete supplier who can create custom mixes based on your requirements. Additionally, they can also provide advice on best practices for working with concrete such as curing times and finishing techniques.