Benefits of Insulating Your Concrete Floor

Energy Efficiency: Insulating your concrete floor can significantly improve the energy efficiency of your home or building. By preventing heat loss through the floor, you can reduce the amount of energy needed to heat or cool your space, resulting in lower energy bills.

Increased Comfort: Insulating your concrete floor can make your space more comfortable to live or work in. Insulation helps to regulate the temperature, preventing cold drafts in the winter and keeping the floor cool in the summer. This can create a more pleasant and comfortable environment for occupants.

Noise Reduction: Insulating your concrete floor can also help to reduce noise transmission between floors. By adding a layer of insulation, you can minimize the impact of footsteps, voices, and other noises, creating a quieter and more peaceful atmosphere.

Enhanced Durability: Insulating your concrete floor can also contribute to its longevity and durability. By providing a protective layer, insulation can minimize moisture infiltration, which can lead to cracks and damage over time. Additionally, insulation can help to prevent the formation of condensation, which can cause corrosion and deterioration of the concrete.

Improved Indoor Air Quality: Insulating your concrete floor can help to improve indoor air quality by preventing the infiltration of moisture, mold, and pollutants from the ground. This can create a healthier living or working environment, particularly for individuals with allergies or respiratory conditions.

Increased Property Value: Insulating your concrete floor can add value to your property. Potential buyers or tenants may see the benefits of an insulated floor, such as energy savings and improved comfort, as attractive features. This can make your property more appealing and potentially increase its market value.

Sustainability: Insulating your concrete floor is an environmentally friendly choice. By reducing energy consumption, you can minimize your carbon footprint and contribute to a more sustainable future. Insulation materials are often made from recycled or renewable resources, further enhancing the eco-friendliness of the insulation installation.

Types of Flooring Insulation for Concrete Floors

Rigid Board Insulation: Rigid board insulation is a popular choice for insulating concrete floors. Made from materials such as expanded polystyrene (EPS), extruded polystyrene (XPS), or polyisocyanurate (polyiso), it is available in various thicknesses to provide different levels of insulation. Rigid board insulation is easy to install and offers excellent thermal resistance, helping to keep the concrete floor warm and energy-efficient.

Spray Foam Insulation: Spray foam insulation is another effective option for insulating concrete floors. It is applied as a liquid and expands to fill the gaps and cracks in the concrete surface, creating a seamless layer of insulation. Spray foam insulation has high thermal resistance and provides an airtight seal, preventing heat loss and air leakage. It also has sound-dampening properties, reducing noise transmission through the concrete floor.

Batt Insulation: Batt insulation, also known as blanket insulation, is commonly used for insulating above-grade concrete floors. It consists of flexible fiberglass or mineral wool batts that are cut to fit between the floor joists. Batt insulation is relatively affordable and easy to install, making it a popular choice for DIY projects. However, it may not be as effective as other types of insulation in terms of thermal resistance and moisture control.

Radiant Floor Heating: Radiant floor heating is a unique type of flooring insulation that not only provides insulation but also offers a heating solution for concrete floors. It involves installing a network of pipes or electric heating elements beneath the concrete surface. The heat generated warms the floor, providing a comfortable and energy-efficient heating system. Radiant floor heating can be combined with other insulation methods to enhance the overall energy efficiency of the concrete floor.

Insulated Concrete Forms (ICFs): Insulated concrete forms are a construction technique that combines insulation and concrete to create a highly insulating flooring system. ICFs consist of interlocking foam panels that are stacked and filled with concrete. The foam panels provide excellent insulation, reducing heat transfer through the concrete floor. ICFs are commonly used in below-grade applications, such as basements, where insulation and structural integrity are essential.

Installation Process for Concrete Floor Insulation

1. Preparing the Surface

Before installing insulation on a concrete floor, it is crucial to prepare the surface properly. Start by removing any existing flooring materials or adhesives from the concrete. Clean the floor thoroughly to ensure there is no dirt, dust, or debris that could affect the installation process. Repair any cracks, unevenness, or damage in the concrete surface to create a smooth and even base for the insulation.

2. Choosing the Right Insulation Material

There are various insulation materials available for concrete floor insulation, such as rigid foam boards, spray foam, or mineral wool. Consider factors like the desired R-value, moisture resistance, and compatibility with other flooring materials when selecting the appropriate insulation material for your project. Consult with professionals or manufacturers to determine the best insulation material for your specific needs.

3. Installing a Vapor Barrier

To prevent moisture from seeping through the concrete floor and into the insulation, it is essential to install a vapor barrier. Lay down a plastic sheet or moisture barrier over the concrete surface, ensuring that it covers the entire area to be insulated. Seal any seams or joints with adhesive tape to create a tight seal and prevent moisture infiltration.

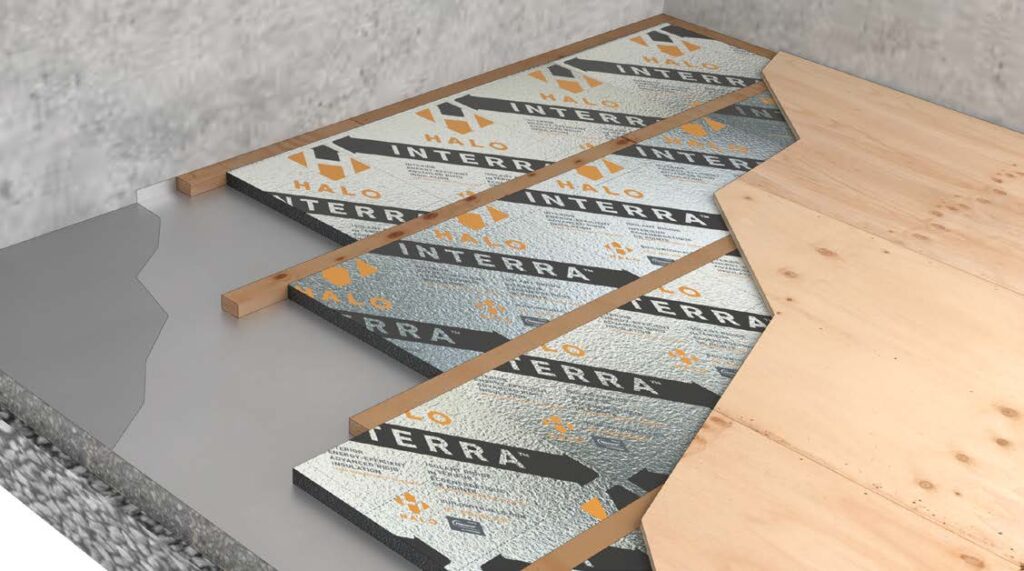

4. Installing the Insulation

Begin the installation process by placing the insulation material on the prepared concrete surface. Cut the insulation boards or rolls to fit the dimensions of the floor accurately. Install the insulation material with the appropriate adhesive or fasteners, following the manufacturer’s instructions. Ensure that the insulation is installed tightly and securely to avoid any gaps or air leakage.

5. Securing the Insulation

After installing the insulation, secure it in place by using mechanical fasteners like screws or nails. This step is particularly important if the insulation material is in the form of rigid foam boards. Attach the fasteners according to the manufacturer’s recommendations, making sure they penetrate the concrete surface adequately and firmly hold the insulation in place.

6. Installing the Flooring

Once the insulation is securely installed, you can proceed with laying the desired flooring material on top. Follow the specific installation instructions for the chosen flooring type, whether it is hardwood, laminate, tile, or carpet. Ensure that the flooring is installed correctly, without compromising the integrity of the insulation layer beneath.

Tips for Choosing the Right Flooring Insulation for Your Concrete Floor

- Consider the R-value: The R-value is a measure of the insulation’s thermal resistance. For concrete floors, it is important to choose insulation with a high R-value to minimize heat loss and increase energy efficiency. Look for insulation materials with R-values specifically designed for use with concrete floors.

- Evaluate moisture resistance: Concrete floors can be prone to moisture, so it is crucial to select insulation that has good moisture resistance. Moisture can lead to mold and mildew growth, which can damage both the insulation and the concrete floor. Insulation materials such as closed-cell foam or moisture-resistant mineral wool are ideal choices for concrete floors.

- Assess acoustic properties: If noise reduction is a concern, consider insulation options that offer good acoustic properties. Concrete floors can transmit sound easily, leading to unwanted noise transfer between floors. Look for insulation materials that are designed to absorb or block sound waves, such as acoustic foam or cork underlayment.

- Consider the installation process: Different insulation materials require different installation methods. Some insulation options, like spray foam, may require professional installation, while others, such as rigid foam boards, can be easily installed as a DIY project. Consider your budget, timeline, and skill level when choosing the right insulation for your concrete floor.

How Thick Should Concrete Floor Insulation Be? – HVACseer.com

How to Build a Floor – Insulation and Screed

How to Insulate Your Existing Concrete Slab with Halou0027s Interra in

insulation below ground floor slab Flooring, Floor insulation

How to Insulate a Concrete Floor Kingspan MEA u0026 India

Related Posts: