They are generally resilient to damage, simple to keep and very simple to clean. While a number of individuals love to use granite or slate for floor surfaces, concrete floor is often just as gorgeous and a lot more affordable. When cleaning polished concrete floor surfaces, you do not need to count on harsh chemical cleaners anymore.

Images about Guide For Concrete Floor And Slab Construction

Guide For Concrete Floor And Slab Construction

In fact concrete floors are not new things, however they were constantly around. Among the factors concrete polishing floors are increasing in need is because they eliminate additional costs which can happen with a brand new build. Below are actually several of the positives to creating your new home with floors of polished concrete or perhaps exposing the concrete floor of your existing home.

Guide for Concrete Floor and Slab Construction – Civil MDC

Keep in mind concrete flooring may be discussed with a few substances including epoxy, an attractive durable finish that can be used someplace in the home. Concrete office flooring is a greenish choice that often outlasts other floor varieties as carpet, tile, wood, and linoleum.

ACI PRC-302.1S-04 Guide for Concrete Floor and Slab Construction

On-Demand Course: Concrete Floor and Slab Construction (302.1R-15

Building Guidelines Concrete Floors, Slabs

Concrete Floor Slab Construction Process – The Constructor

PDF) Guide for concrete floor and slab construction mahmut

Building Guidelines Concrete Floors, Slabs

Concrete Floor Slab Construction Process – The Constructor

ACI 302.1R-04 Guide for Concrete Floor and Slab Construction by

Recommendations in new ACI 302.1 Concrete Floors Guide Concrete

5+ Types of Concrete Slabs u2013 Construction – Uses – Definecivil

Two-Way Concrete Flat Slab Floor System Dimensions u0026 Drawings

Concrete slab construction, Pouring a concrete slab, Cement floors

Related Posts:

- Acid Wash Concrete Floor Colors

- Concrete Floor Thickness For A Garage

- Concrete Floor For Bathroom

- Interior Concrete Floor Ideas

- Kitchen Stained Concrete Floors

- Concrete Floor Tile Thickness

- How To Stain Concrete Floors DIY

- DIY Concrete Floor Grinding

- Concrete Floor Damage

- Faux Stained Concrete Floors

Guide For Concrete Floor And Slab Construction

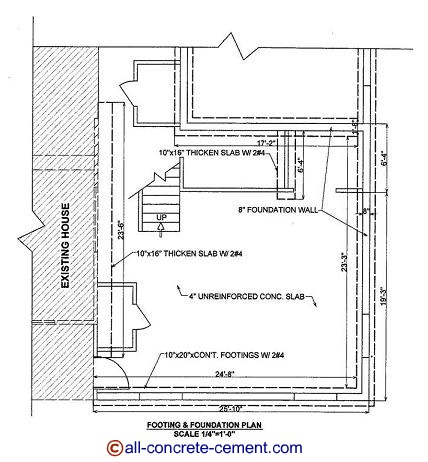

Building a concrete floor or slab is no small task. It requires precise measurements, planning, and execution to ensure that you end up with a surface that’s level and durable. Here we will discuss the steps for constructing a concrete floor or slab to ensure that you have all the information you need to get the job done right.

Preparation

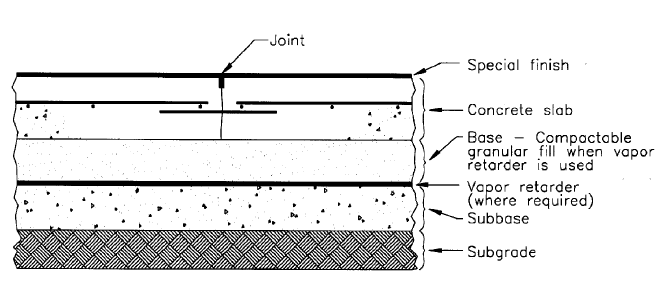

The most important step in constructing any type of concrete floor or slab is the preparation. This includes making sure the area where the concrete will be poured is free of debris and has been properly leveled. You’ll also want to make sure that any reinforcement materials like rebar and mesh are in place before you begin pouring the concrete.

Mixing The Concrete

Once the area has been prepared, it’s time to mix the concrete. This is done by combining sand, gravel, and cement with water in a large mixing container. The proportions of each ingredient will vary depending on the type of concrete being used, so it’s important to follow the manufacturer’s instructions for mixing correctly. Once the concrete is mixed, it’s ready to be poured.

Pouring The Concrete

Pouring the concrete is a crucial step in creating a successful floor or slab. To ensure that the concrete is evenly distributed, it should be poured in several thin layers rather than one thick layer. This will also allow for better curing and help prevent cracking. After each layer has been poured, it should be tamped down with a spiked roller or hand tamper to remove air pockets and create a smooth surface.

Curing The Concrete

Once the pouring process is complete, the concrete must be allowed to cure before it can be used. This process typically takes several days, depending on environmental factors like temperature and humidity. During this time, it’s important to keep the area moist by covering it with plastic sheeting or spraying it with water periodically. This will help ensure that the concrete cures properly and reaches its full strength.

Finishing The Concrete

Once the curing process is complete, it’s time to finish off your concrete floor or slab. This can involve using a variety of tools such as trowels, floats, and edgers to smooth out any rough edges or imperfections in the surface. You may also choose to apply a sealant or stain to give your concrete an attractive finish.

FAQs About Concrete Floor And Slab Construction

Q: What type of reinforcement materials are used when constructing a concrete floor or slab?

A: Reinforcement materials like rebar and mesh are often used when constructing a concrete floor or slab. These materials provide additional support for the structure and help prevent cracking. They should be installed before pouring the concrete in order to provide maximum stability and strength.

Q: How long does it take for a concrete floor or slab to cure?

A: The curing process typically takes several days, depending on environmental factors like temperature and humidity. It’s important to keep the area moist during this time by covering it with plastic sheeting or spraying it with water periodically in order to ensure proper curing and maximum strength.

Q: What type of tools are used when finishing a concrete floor or slab?

A: Finishing tools such as trowels, floats, and edgers are often used when finishing a concrete floor or slab. These tools can be used to smooth out any rough edges or imperfections in the surface and create a professional-looking finish. Additionally, sealants or stains can be applied to give your concrete an attractive finish.