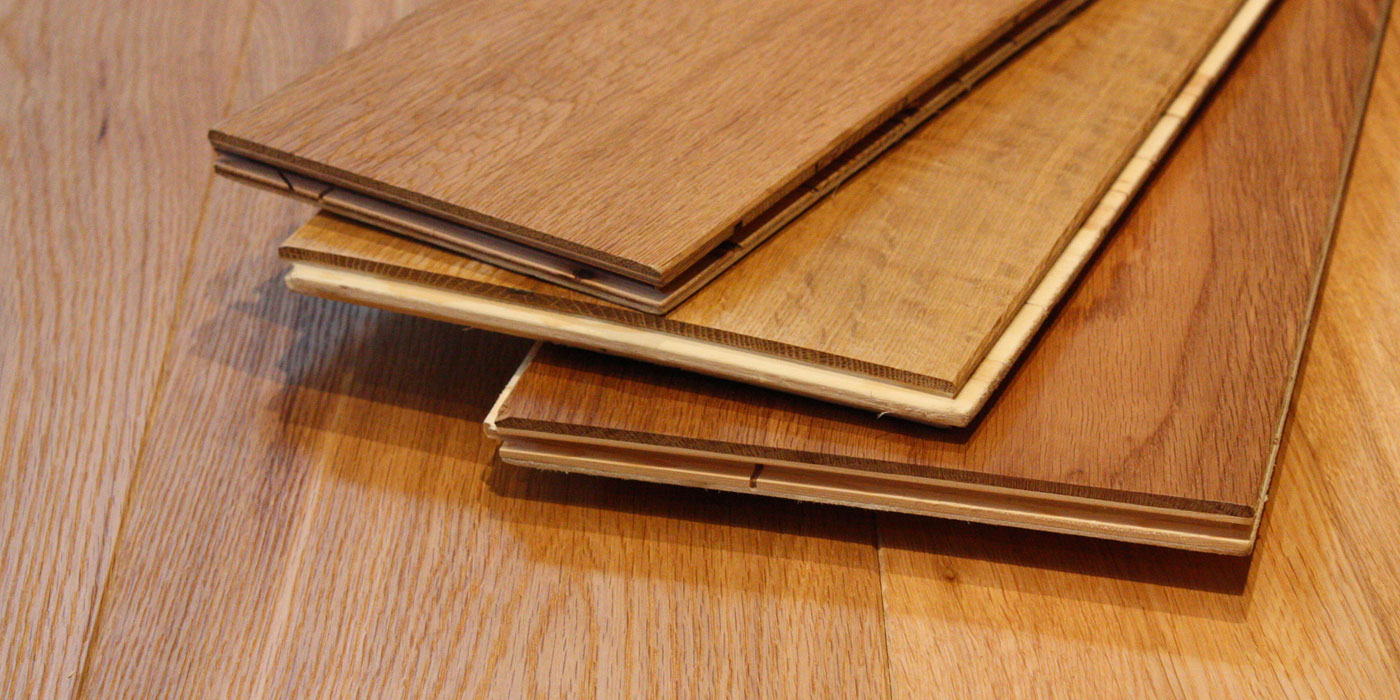

Introduction to Engineered Hardwood Flooring

Engineered hardwood flooring stands out as a preferred choice for homeowners and designers, delivering a blend of durability and aesthetic allure. Below, we break down the key aspects of this popular flooring option.

-

Composite Construction:

- Engineered hardwood is crafted by combining real wood with synthetic materials, offering a harmonious balance of natural beauty and enhanced performance.

-

Real Hardwood Veneer:

- The top layer, or veneer, is crafted from real hardwood species like oak, maple, or walnut.

- Carefully selected veneers ensure consistent grain patterns and color variations, contributing to the flooring’s captivating visual appeal.

-

High-Density Fiberboard (HDF) Core:

- Beneath the veneer, multiple layers of cross-laminated HDF provide a robust and stable core.

- Cross-grain construction enhances strength and stability, minimizing the risk of warping or cupping over time.

-

Protective Layer for Durability:

- To enhance durability and resist moisture, a protective layer is applied on top of the veneer.

- Typically composed of scratch-resistant materials like aluminum oxide, this layer shields the flooring from daily wear and tear, including scratches, stains, and fading.

-

Versatile Installation Options:

- Engineered hardwood offers flexibility in installation methods, including floating, stapling, or direct glue-down.

- Unlike solid hardwood, which is often limited in installation options, engineered hardwood can be installed in various areas, including basements and kitchens, addressing concerns related to moisture.

-

Moisture Resistance:

- Engineered hardwood’s composition and construction make it more resistant to moisture, expanding its suitability for areas where solid wood flooring may be less advisable.

-

Aesthetic Appeal and Warmth:

- By marrying real hardwood with synthetic components, engineered hardwood maintains the natural warmth and aesthetic charm of wood while providing additional strength and stability.

The Manufacturing Process of Engineered Hardwood Flooring

The manufacturing process of engineered hardwood flooring involves several steps that transform raw materials into a finished product. This section provides an overview of the key processes involved in creating engineered hardwood flooring.

- Material Selection: The process begins with the careful selection of materials. Engineered hardwood flooring typically consists of a top layer of hardwood veneer, multiple layers of plywood or high-density fiberboard (HDF), and a stabilizing bottom layer. The hardwood veneer is chosen for its aesthetic qualities, while the other layers provide stability and strength.

- Veneer Slicing: The selected hardwood veneer is sliced into thin strips using either a rotary cutting or saw-cutting method. This process determines the appearance of the final product, as the slicing technique affects the grain pattern and texture of the veneer.

- Drying and Conditioning: The sliced veneer strips undergo a drying and conditioning process to reduce their moisture content. This step is crucial to prevent warping or buckling of the flooring during installation or exposure to varying humidity levels.

- Layer Assembly: The next step involves assembling the layers of the engineered hardwood flooring. The veneer strips are glued or bonded to the plywood or HDF layers using adhesives that are specifically formulated for this purpose. The layers are stacked together in a cross-grain configuration, enhancing the stability and durability of the flooring.

- Pressing and Bonding: The assembled layers are placed in a hydraulic press, where heat and pressure are applied to bond them together. This process ensures a strong and durable bond between the layers, creating a solid and stable flooring product.

- Finishing: Once the layers are pressed and bonded, the engineered hardwood flooring goes through a finishing process. This involves sanding the surface to create a smooth and even texture. Stains, sealants, and coatings may also be applied to enhance the appearance and protect the flooring from wear and tear.

- Quality Control: Before the engineered hardwood flooring is packaged and shipped, it undergoes rigorous quality control checks. These checks ensure that the flooring meets industry standards and specifications, including dimensional accuracy, moisture content, and appearance.

Materials Used in Engineered Hardwood Flooring Production

Engineered hardwood flooring is made using a combination of materials that are carefully selected for their strength, durability, and aesthetic appeal. These materials include:

Hardwood veneer: The top layer of engineered hardwood flooring is typically made from a thin slice of real hardwood. This veneer is chosen for its natural beauty and can be made from a variety of hardwood species, such as oak, maple, or walnut. The hardwood veneer is responsible for giving engineered hardwood flooring its authentic wood appearance.

Plywood core: The core layer of engineered hardwood flooring is made from layers of plywood. These layers are glued together in a cross-grain pattern, which adds stability and strength to the flooring. The plywood core is designed to resist expansion and contraction caused by changes in humidity and temperature, making engineered hardwood flooring more dimensionally stable than solid hardwood.

Adhesive: To bond the hardwood veneer to the plywood core, a strong adhesive is used. This adhesive is typically a type of resin that is specifically formulated for flooring applications. It ensures a secure and long-lasting bond between the veneer and core layers, preventing delamination and warping over time.

Finish: After the layers are bonded together, the engineered hardwood flooring is typically finished with a protective coating. This coating can be made from various materials, such as polyurethane or aluminum oxide. The finish enhances the durability of the flooring, making it resistant to scratches, stains, and wear.

Benefits of Engineered Hardwood Flooring

- Durability: Engineered hardwood is highly durable. The construction of multiple layers, each running in opposite directions, makes it less prone to expansion and contraction due to changes in humidity and temperature. This stability makes it suitable for various environments, including areas with fluctuating moisture levels, such as kitchens and basements.

- Versatility: One of the key benefits of engineered hardwood is its versatility. It can be installed in various ways, including nail-down, glue-down, and click-lock systems. This flexibility allows it to be used in virtually any room in your home.

- Aesthetic Appeal: Engineered hardwood retains the natural beauty of wood. With a wide range of wood species, finishes, and surface textures available, you can find an engineered hardwood flooring option that complements your interior design style. Whether you prefer the rustic charm of oak or the sleek sophistication of maple, there’s a choice for every taste.

- Cost-Effective: While solid hardwood flooring can be expensive, engineered hardwood provides a more cost-effective alternative without sacrificing the genuine wood look and feel. It offers excellent value for your investment.

- Easy Installation: Engineered hardwood is designed for easy installation. The click-lock systems, in particular, make it a great choice for DIY enthusiasts. Additionally, its stability simplifies installation, reducing the likelihood of warping or buckling.

- Maintenance: Maintenance of engineered hardwood is straightforward. Regular sweeping and occasional mopping with a recommended wood floor cleaner are usually sufficient to keep it looking beautiful. The wear layer can also be refinished multiple times, increasing the longevity of the flooring.

- Eco-Friendly: Engineered hardwood is often considered more environmentally friendly than solid hardwood. It utilizes less of the top hardwood layer, which can reduce the overall impact on forests. Additionally, the plywood base is often made from sustainable and fast-growing wood species.

- Resale Value: Installing engineered hardwood can enhance the resale value of your home. Its timeless appeal and durability are attractive features for potential buyers.

Applications of Engineered Hardwood Flooring

Now that we’ve discussed the benefits of engineered hardwood flooring let’s explore its various applications.

- Living Rooms: The living room is a popular choice for engineered hardwood flooring due to its aesthetic appeal and durability. It can withstand heavy foot traffic and complements various design styles.

- Kitchens: Engineered hardwood is a suitable choice for kitchens, provided that it is properly maintained and spills are cleaned promptly. Its ability to handle moisture fluctuations makes it a practical option.

- Dining Rooms: The timeless elegance of hardwood flooring makes it a great fit for dining rooms. It sets the stage for formal dinners and family gatherings.

- Bedrooms: Engineered hardwood adds warmth and character to bedrooms. The vast array of wood species and finishes allows you to create a cozy or sophisticated ambiance, depending on your preference.

- Basements: Engineered hardwood is an excellent choice for basements. Its multi-layered construction makes it less susceptible to moisture-related issues. Be sure to install it over a moisture barrier to further protect against dampness.

- Home Offices: With the growing trend of remote work, many homeowners are creating home offices. Engineered hardwood not only adds a touch of professionalism to these spaces but is also durable enough to withstand daily use.

- Hallways and Entryways: High-traffic areas benefit from the durability of engineered hardwood. It’s an attractive option for hallways and entryways, creating a welcoming first impression.

- Retail Spaces: Beyond residential applications, engineered hardwood is also used in commercial settings. Its versatility and durability make it a great choice for retail spaces, restaurants, and offices.

- Apartments and Condos: Engineered hardwood is often chosen in multi-unit housing developments. It offers a balance between cost-effectiveness and quality, making it a popular choice for property developers and managers.

What is engineered wood flooring?

Related Posts:

- Hardwood Flooring Rustic Look

- Using Hardwood Flooring For Stairs

- Hardwood Floor Stain Removal Tips

- Hardwood Floor Installation Cost Vancouver

- Vinyl Tile Hardwood Flooring

- Hardwood Flooring Black Walnut

- Images Of Maple Hardwood Floors

- Finishing Hardwood Floors By Hand

- American Hickory Hardwood Flooring

- Hardwood Floor Cleaner For Scratches