Therefore, you are able to get the hands of yours on anything, starting from pretty smooth to a bit rough and all the way up to pebbled surfaces. The padded part of the vinyl is within the middle layer, between the wear layer as well as the backing. Vinyl flooring is a lot more durable compared to the various other kinds of flooring. It is so tough and hard-wearing that you do not have to spend for the frequent maintenance of its.

Images about How To Make A Vinyl Floor Roller

How To Make A Vinyl Floor Roller

The designs and versatility of laminate make it a good choice for any room. If you are comfortable dealing with planks, tiles or even sheets, there's a vinyl floors for you. Almost all of the time, this can be due to no-slip sheets laid out on the particular sheets of vinyl. What's more, it can be purchased in planks or maybe tiles which means homeowners can experiment and obtain the flooring appear they want.

Luxury Vinyl Tile Installation (DIY) Family Handyman

There are numerous reasons why people still get vinyl sorts of flooring and why it still remains to become a popular choice for most homeowners; however, as with other things, it additionally has its fair share of drawbacks. On top of that, these good quality vinyl floors can cost several hundred pounds or much more to fit for a large floor.

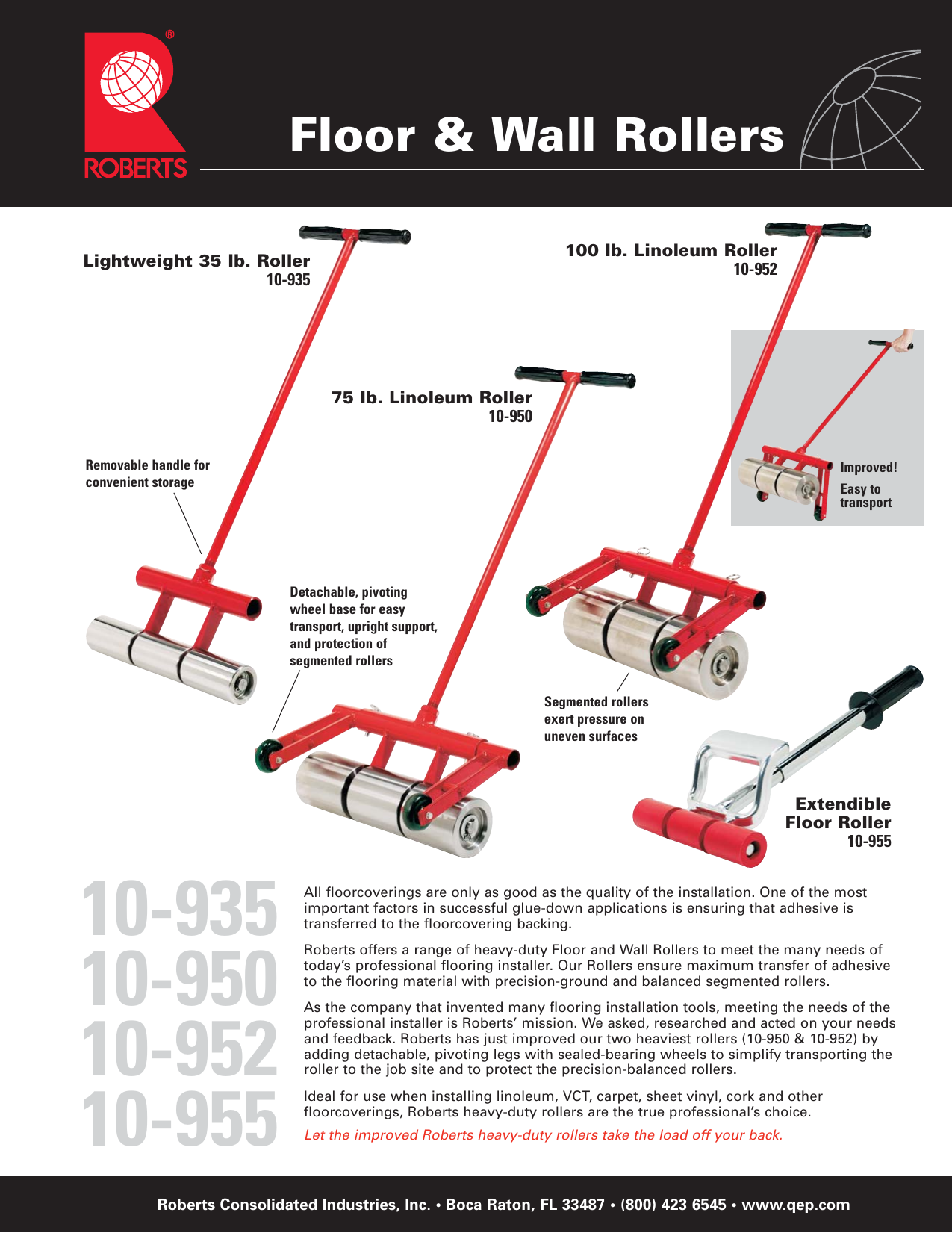

Linoleum Roller Product

Shop project, tile roller

Roberts 10-950 75-Pound Heavy Duty Vinyl and Linoleum Floor

Roberts 10-935 35-Pound Lightweight Vinyl, Linoleum and Carpet Flooring Roller with Chrome-Plated Rollers, Insert Axles and Removable Handle for Easy

35 lb. Floor Roller – Roberts Consolidated

Roberts 10-955 Extendable Floor Roller Product Brochure Manualzz

The Best Alternative for a 100-Pound Roller on Vinyl Flooring Hunker

How to Paint Linoleum Floors or Vinyl Flooring for a Quick Redo

How to Install Vinyl Plank Flooring

Floor Rollers at Lowes.com

How to Lay a Vinyl Tile Floor – This Old House

How to Lay a Vinyl Tile Floor – This Old House

Related Posts:

- Vintage Style Vinyl Flooring

- Coloured Vinyl Flooring Tiles

- About Vinyl Flooring

- Retro Vinyl Floor Covering

- Fixing Vinyl Flooring

- Vintage Oak Vinyl Flooring

- Single Sheet Vinyl Flooring

- Dark Wood Effect Vinyl Flooring

- Terrazzo Vinyl Flooring

- How To Get Rid Of Stains On Vinyl Flooring

How To Make A Vinyl Floor Roller

Vinyl flooring is an attractive and durable flooring option that can last for years. If you want to install it yourself, you need to invest in a vinyl floor roller. This piece of equipment will make sure your floor is properly leveled and free of air bubbles and bumps. Making your own vinyl floor roller is not difficult, and the cost savings can be considerable. Here’s how to do it.

Gather Your Supplies

The first step in making your own vinyl floor roller is to gather the supplies you’ll need. You’ll need a piece of wood, such as plywood or particle board, that is about 2 feet by 4 feet in size. You’ll also need a length of PVC pipe that is at least 1 inch in diameter and a length of steel pipe that is 1/2 inch in diameter. You’ll also need a few screws, some washers, and nuts, as well as some adhesive caulking.

Create The Base

Once you have all of your supplies gathered, you can begin creating the base for your vinyl floor roller. Start by cutting the piece of wood into two equal pieces with a saw. Use the adhesive caulking to affix the two pieces together so that they form a sturdy base.

Attach The PVC Pipe

Next, you’ll need to attach the PVC pipe to the base. Start by drilling two holes on either side of the base, near one end. Place the PVC pipe into the holes and secure it with screws, washers, and nuts. This will keep the PVC pipe firmly in place on the base.

Attach The Steel Pipe

Now it’s time to attach the steel pipe to your base. Start by drilling two additional holes at one end of the base, directly across from each other. Place the steel pipe into these holes and secure it with screws, washers, and nuts as you did with the PVC pipe.

Attach The Handle

Finally, you’ll need to attach a handle to your vinyl floor roller so you can use it properly. You can use any type of handle you’d like; just make sure it is securely attached to one end of the steel pipe with screws or bolts. You may also want to add some padding or insulation around the handle for comfort and grip.

You’re Done!

Once you’ve finished attaching all of the pieces together, your vinyl floor roller is ready to use! Just roll it over your vinyl flooring and it will help ensure that it is properly leveled and free of air bubbles and bumps.

FAQs:

Q: What type of wood should I use for my vinyl floor roller?

A: Plywood or particle board are both good options for making your vinyl floor roller since they are sturdy and easy to work with. However, any type of wood should work as long as it is thick enough to hold up under pressure when rolling over the vinyl flooring.

Q: How much PVC pipe do I need?

A: The length of PVC pipe you need will depend on the size of your base; however, a length of 1 inch in diameter should be sufficient for most sizes of bases.

Q: Can I use any type of handle for my vinyl floor roller?

A: Yes, you can use any type of handle you’d like; just make sure that it is securely attached to one end of the steel pipe with screws or bolts so it won’t come off while you’re using it.

/cdn.vox-cdn.com/uploads/chorus_asset/file/19494355/howto_vinylfloor_05.jpg)

/cdn.vox-cdn.com/uploads/chorus_asset/file/19494137/howto_vinylfloor_08.jpg)