Wet polishing creates waste slurry which effortlessly transfers into hard-to-find hard to reach places. On a new concrete, stain concrete flooring surfaces making companies advise letting the concrete treatment for no less than a month. In addition to making polished concrete unbelievably renewable, concrete is certainly the least expensive flooring option offered.

Images about In Situ Concrete Floor Slab

In Situ Concrete Floor Slab

The ideas of painting both polished concrete as well as terrazzo flooring surfaces include the most crucial task of all, discovering the ideal paint type for the job. They are the best applications for polished concrete flooring surfaces as public authorities compute the long term cost benefits of other floorings. Apart from that, the concrete floor improving supplies a feeling of security to home owners.

Concrete Floor Slab Construction Process – The Constructor

While concrete polishing shines concrete to a high gloss, it readies the skin pores in the concrete. Polished concrete floors makes perfect sense for business people that would like an enticing floor that doesn't need to be waxed from the conclusion of every day. Polished concrete flooring is an economical way to other floorings and definately will provide you with exactly the same mirror as finish.

Explainer: In Situ Concrete SkyriseCities

Upper Floors

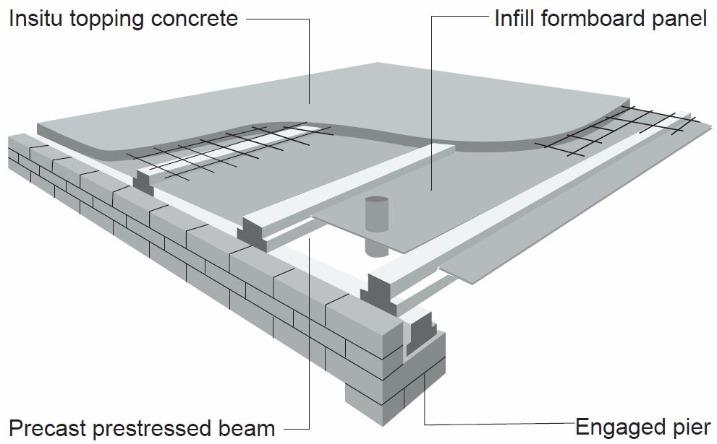

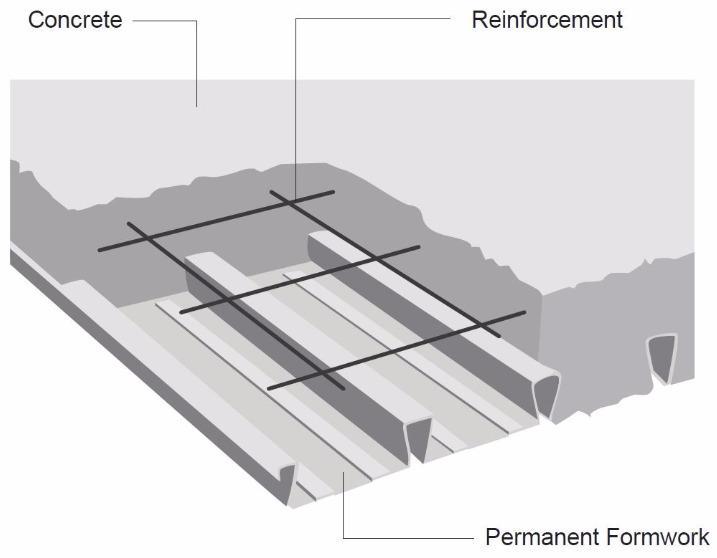

Precast cast-in-situ concrete foors with permanent formwork: 1

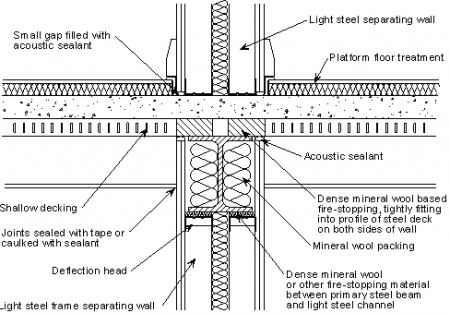

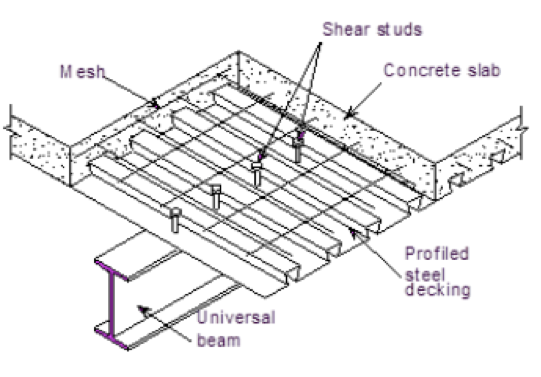

Floor systems – SteelConstruction.info

Concrete foundation wall reinforcing BRANZ Build

Floor systems – SteelConstruction.info

Upper Floors

Building Guidelines Concrete Floors, Slabs

Concrete floor – Designing Buildings

Suspended Floors – All You Need To Know – Thermohouse

Building Guidelines Concrete Floors, Slabs

Guidelines for a one-way concrete flooring system Brewer Smith

Related Posts:

- Acid Wash Concrete Floor Colors

- Concrete Floor Thickness For A Garage

- Concrete Floor For Bathroom

- Interior Concrete Floor Ideas

- Kitchen Stained Concrete Floors

- Concrete Floor Tile Thickness

- How To Stain Concrete Floors DIY

- DIY Concrete Floor Grinding

- Concrete Floor Damage

- Faux Stained Concrete Floors

What is In Situ Concrete Floor Slab?

In Situ Concrete Floor Slab is a type of concrete floor slab that is poured and cured on the construction site without having to be precast. This type of concrete floor slab is a popular choice for commercial, industrial and residential projects as it is strong and durable. It also offers a wide range of design options and can be tailored to meet the needs of any project.

Advantages of In Situ Concrete Floor Slab

In Situ Concrete Floor Slab is a cost-effective choice for many projects due to its low cost and quick installation time. This type of concrete floor slab is also very strong and durable, making it ideal for heavy-duty applications. The strength of the slab can be adjusted by changing the mix design or adding reinforcements such as steel bars or wire mesh. Additionally, In Situ Concrete Floor Slab can be designed to meet any specific aesthetic requirements, as it can be poured and cured into a variety of shapes, colors, textures, and finishes.

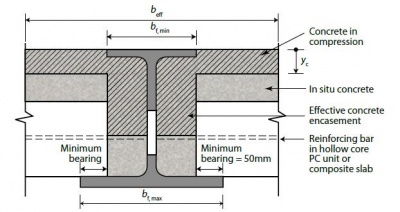

Design Considerations for In Situ Concrete Floor Slab

When designing an In Situ Concrete Floor Slab, there are several important factors to consider. The first is the size and shape of the slab. The size should be determined based on the amount of space available in the area where it will be installed. The shape should also be taken into account when designing the slab, as certain shapes may require additional reinforcing materials or different pouring techniques. Additionally, the mix design should be chosen carefully to ensure that the slab has the desired strength and durability. Finally, any aesthetic requirements should also be taken into account when designing an In Situ Concrete Floor Slab.

Installation of In Situ Concrete Floor Slab

The installation process for an In Situ Concrete Floor Slab typically takes several days to complete. First, a subgrade must be prepared to provide a firm base for the slab. Next, formwork must be constructed to contain the concrete while it cures. Once these steps are complete, concrete can then be poured into the formwork and allowed to cure. Finally, once the concrete has cured, it can be finished with a sealant or other finishing materials to achieve the desired aesthetic effect.

FAQs on In Situ Concrete Floor Slab

Q: What are some advantages of using an In Situ Concrete Floor Slab?

A: Some advantages of using an In Situ Concrete Floor Slab include its low cost, quick installation time, strength and durability, and ability to be tailored to meet any specific aesthetic requirements.

Q: What are some design considerations when using an In Situ Concrete Floor Slab?

A: When designing an In Situ Concrete Floor Slab, factors such as size and shape, mix design, and any aesthetic requirements should all be taken into account. Additionally, reinforcing materials such as steel bars or wire mesh may need to be added in order to achieve the desired strength and durability.

Q: How long does it take to install an In Situ Concrete Floor Slab?

A: The installation process for an In Situ Concrete Floor Slab typically takes several days to complete. This includes preparing a subgrade, constructing formwork, pouring concrete, and finishing with a sealant or other finishing materials.