Polished concrete flooring is among the least expensive options as compared to other material used for flooring these days. It really works with the lime content in the floor it is quite unpredictable but generally comes out looking rather good. It is additionally a good idea to survey the concrete floor frequently and get rid of any extra substances, including stickers or gum, and check out it for damage.

Images about Prefabricated Concrete Floor Systems

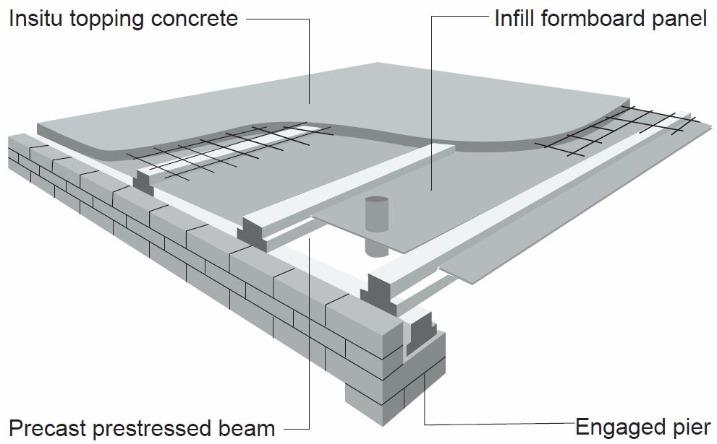

Prefabricated Concrete Floor Systems

Concrete floors are practical and functional. In the summer season, the concrete floor absorbs moisture from the earth to keep it cool. In the first place, there is an excellent sense of affordability in relation to these concrete floors, a great deal that many men and women now notice them when the best option when it comes to flooring.

Precast Concrete Floor Systems Types Of Precast Concrete Floors

There are several locations that find this particular type of polished concrete flooring pretty helpful. The concrete floor also has different amounts of absorbency along with the acid giving the floor a marble result which can look hitting. To polish the concrete floors brings out the beauty of the floor and actually leaves home owners with the most effective building material.

PreCast Construction Precast concrete, Precast concrete slabs

Reinforced concrete precast core floor slab – HOLLOWCORE – concast

Taxonomy – Precast concrete floor with reinforced concrete topping

STRUCTURE magazine Creating an Opening in Existing Floors

Hollow-core slab – Wikipedia

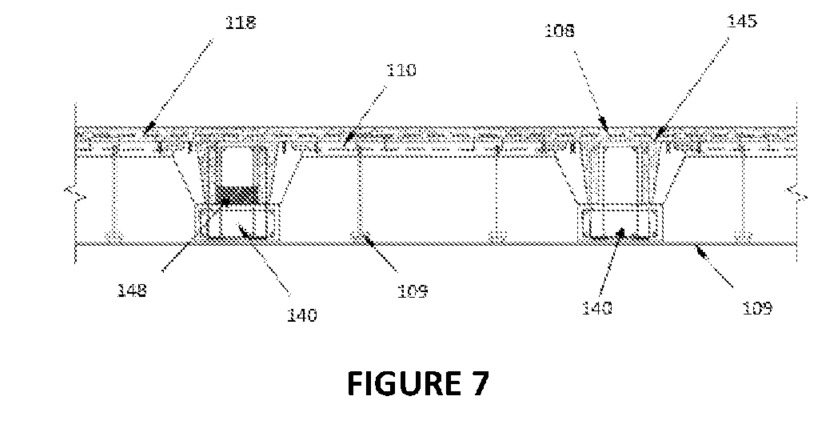

Precast concrete formwork, floor system and a method of

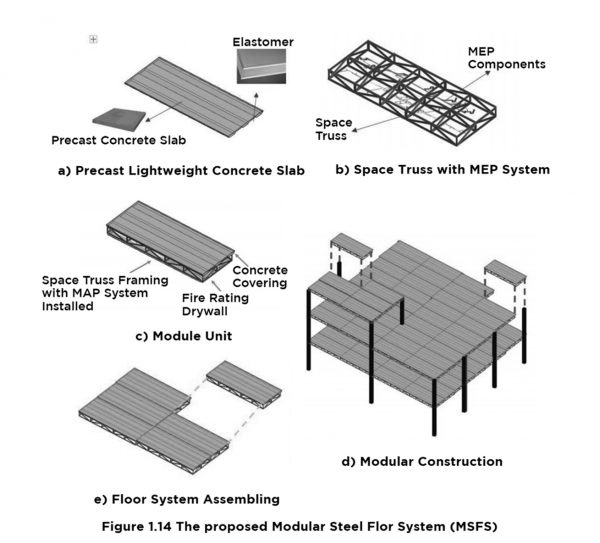

Researchers Develop New Commercial Floor Truss System SBC Magazine

Lighter, Stronger Precast Concrete Floor System – NPCA

Precast Concrete – an overview ScienceDirect Topics

Rhino Concrete

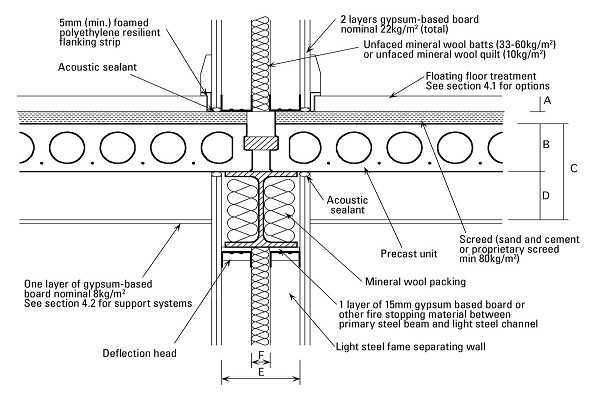

Upper Floors

Hollowcore Residential Applications

Related Posts:

- Applying Concrete Floor Paint

- Non Slip Concrete Floor Sealer

- How To Paint Concrete Garage Floor

- Outdoor Concrete Floor Ideas

- Concrete Floor Covering Ideas

- Cracks In Polished Concrete Floors

- Drylok Concrete Floor Paint Colors

- Polished Concrete Floor Thickness

- Residential Stained Concrete Floors

- Cheap Concrete Floor Finishes

Prefabricated concrete floor systems are becoming increasingly popular for residential, commercial and industrial projects due to their cost efficiency, speedy installation and superior strength. Prefabricated floors are pre-made at a factory and then transported to the construction site, where they are quickly and easily installed.

Concrete floors are incredibly durable and can withstand wear and tear from heavy foot traffic, machinery or even weathering. They are also highly resistant to fire, making them ideal for high-risk areas such as factories or warehouses. With their superior strength, they can support large loads, making them ideal for industrial projects.

Prefabricated concrete floors can be customized to the exact needs of the project. Different types of reinforcement can be used, such as steel mesh or fiberglass, to make the floor even stronger. Colors and textures can also be added to give the floor a unique look.

Installation is quick and easy, with no need for extensive on-site labor. The pre-made sections of floor can simply be connected together using connectors or adhesives. This makes them ideal for tight deadlines or emergency repairs.

Prefabricated concrete floors are also a cost-effective way to provide a durable, long-lasting floor that meets all safety requirements. The cost of prefabricated concrete floors is typically lower than traditional poured concrete due to the speed and ease of installation.

Overall, prefabricated concrete floor systems offer numerous benefits for residential, commercial and industrial projects alike. They are strong, durable, customizable and cost effective. If you’re looking for a reliable floor that can take whatever you throw at it, then prefabricated concrete floors may be the perfect choice.