In a factory set up where flooring is actually at the mercy of a lot of wear and tear, option of the appropriate flooring is essential, since it's an element of the original investment and it is often dispersed across a big area. You should most certainly consider an epoxy flooring coating if you are contemplating changing your sports surfaces.

Images about Self Leveling Epoxy Floor Coating Formulation

Self Leveling Epoxy Floor Coating Formulation

Epoxy flooring is additionally very easy to clean because there is nothing for toxins to hang onto. These could be offered the preferred styles after mixing some dyes agent to them. And moreover the epoxy floors paint is really simple to apply and maintain. It is not too costly and will outlast other floor coatings. Actually, it is smarter than most other choices.

WO2016187380A1 – Epoxy coating composition – Google Patents

If your epoxy floor paint is solvent-based it is more dangerous but stronger than epoxy which is water-based. The benefits are a lot when it comes to installing epoxy flooring in your garage or shop. Manufacturing epoxy floor coating things stand above the rest in giving you the highest quality as well as best performance in manufacturing floor applications.

WO2016166361A1 – Floor coating compositions – Google Patents

Construction of industrial self-leveling epoxy flooring – ISOMAT

Epoxy Resins for Civil Engineering Applications – ppt video online

Finding the Right u0027Levelu0027 2013-11-01 PCI Magazine

Why the Best DIY Garage Floor Coating Kits are not Epoxy All

PDF) The versatility of ambient curing waterborne epoxy resin

5 Benefits of Self-Leveling Epoxy Flooring Black Bear Coating

WO2016166361A1 – Floor coating compositions – Google Patents

A Webinar on Epoxy Self Leveling Flooring

Floor Coating Systems Systems Stronghold Floors

Self Leveling Epoxy Floor – Step by Step how to Apply (Ktisofloor)

Performance Epoxy 100% Solids self leveling epoxy – Seal-Krete

Related Posts:

- Epoxy Gloss Floor Paint

- Epoxy Concrete Floor Covering

- Thick Epoxy Floor Coating

- Epoxy Paint Floor Finish

- Epoxy Floor Coating For Basement

- White Metallic Epoxy Floor

- Metallic Epoxy Floor Installation

- Red Epoxy Floor

- Pearl White Epoxy Floor

- Clear Epoxy Shower Floor

Introduction

Self-leveling epoxy floor coatings are a great choice for flooring in industrial, commercial, and residential settings. They provide a high level of durability and longevity, making them an attractive option for many types of flooring. But what is the formulation for self-leveling epoxy floor coatings? Here, we explore the ingredients and steps necessary to create a self-leveling epoxy floor coating.

What is Self Leveling Epoxy Floor Coating?

Self-leveling epoxy floor coatings are a type of coating used to protect and enhance the look of concrete and other types of floors. They are made up of a two-part epoxy resin and a hardener that is mixed together to form a thick liquid that is applied to the floor. The mixture then levels itself out, creating a smooth and durable surface that is resistant to wear and tear.

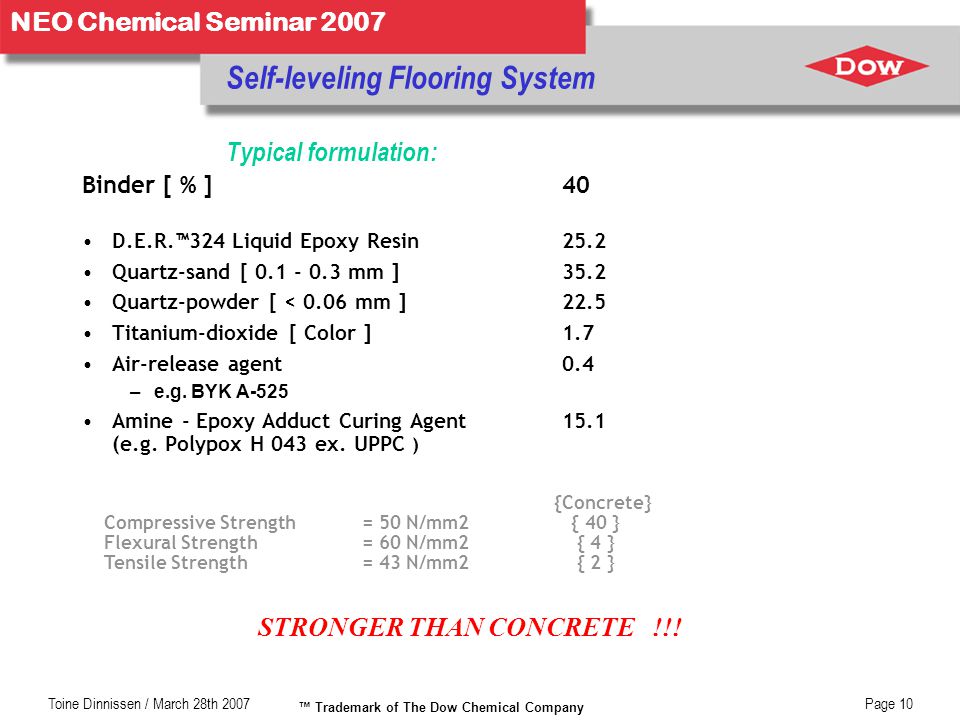

Formulation Components

Self-leveling epoxy floor coatings are composed of several components, including:

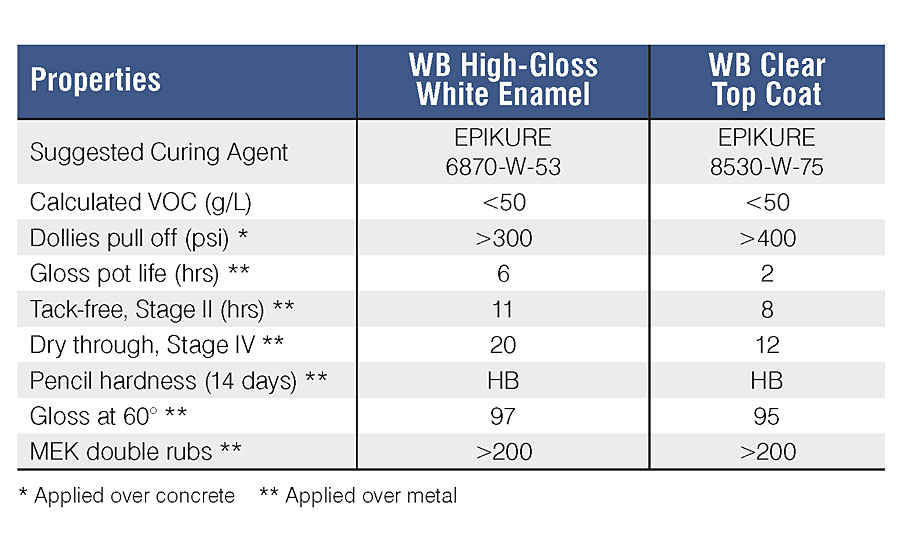

• Epoxy resin: This is the main component of the coating, providing a strong bond between the substrate and the coating. It also imparts a glossy finish to the surface.

• Hardener: This is used to speed up the curing process and increase durability. Hardeners can be either liquid or powder form.

• Pigments: This can be added to give the coating a range of colors. It also helps to increase UV resistance and improve wear resistance.

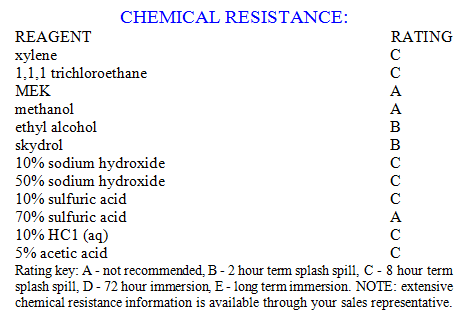

• Solvents: This helps with the application process by thinning out the coating and allowing it to flow more easily. It also helps to reduce VOC emissions from the coating.

• Fillers: This is used to add strength and durability to the coating. Fillers can either be organic or inorganic depending on the desired result.

• Polymer additives: These additives help to improve adhesion, impact resistance, flexibility, and chemical resistance.

• Additives: These additives can be used to modify the properties of the coating such as viscosity, cure rate, or color stability.

Mixing Instructions

Once all of the components have been gathered, they must be mixed together according to specific instructions in order to create a self-leveling epoxy floor coating. Generally speaking, this involves adding all of the components into a container in specific order (e.g., adding resin first, then hardener) and mixing until everything has been thoroughly combined. It is important to note that not all formulations are the same; some may require additional steps or different ratios of components in order to achieve the desired results.

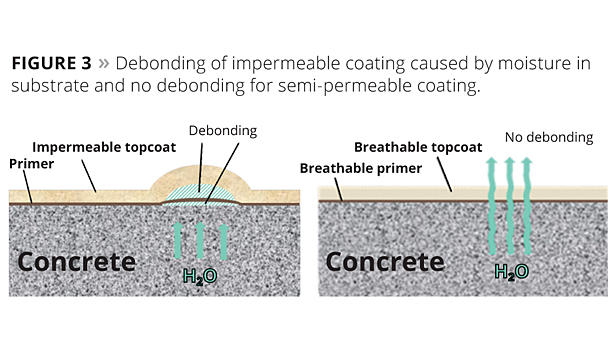

Application Process

Once the formulation has been mixed together properly, it can then be applied using either a roller or brush. For best results, it is important that the surface being coated is clean and free of any dirt or debris before beginning application. Additionally, it is important not to apply too much pressure when rolling or brushing on the coating as this could cause air bubbles or other imperfections in the finished product.

Curing Process

After application, it is important that the floor is allowed to cure for at least 24 hours before subjecting it to traffic or heavy use. During this time, it is important that proper ventilation is provided in order to avoid any off-gassing from the curing process. Additionally, temperature should be monitored during this time period as well since extreme temperatures can interfere with proper curing times.

Common Questions

Q: How long does self-leveling epoxy floor coatings last?

A: Self-leveling epoxy floor coatings typically last between 8-10 years with proper maintenance and care.

Q: Is self-leveling epoxy floor coatings slip resistant?

A: Yes, self-leveling epoxy floor coatings provide excellent slip resistance due to their high level of adhesion and durability when properly installed and maintained regularly.

Q: What surfaces can self-leveling epoxy floor coatings be applied on?

A: Self-leveling epoxy floor coatings can be applied on both concrete and wood surfaces as long as they are