Exploring the Principles of Suspended Concrete Floor Slab Design

Suspended concrete floor slabs are a common feature in modern construction, providing strong and durable flooring solutions for various types of buildings. Understanding the principles behind their design is crucial to ensure the stability and longevity of these structures. Let’s talk about the key principles that govern the design of suspended concrete floor slabs.

- Load Distribution: One of the fundamental principles of suspended concrete floor slab design is load distribution. The slab must be able to distribute the applied loads evenly across its entire surface to prevent localized stress concentrations. This is achieved by using an appropriate structural layout and reinforcement pattern, ensuring that the load is transferred efficiently to the supporting beams or walls.

- Deflection Control: Controlling deflection is another critical aspect of suspended concrete floor slab design. Excessive deflection can lead to structural integrity issues and cause discomfort for occupants. Designers must consider factors such as acceptable deflection limits, span-to-depth ratios, and the type and arrangement of reinforcement to ensure the slab remains within acceptable deflection limits under various loading conditions.

- Crack Control: Crack control is essential to maintain the durability and aesthetic appeal of suspended concrete floor slabs. By incorporating proper reinforcement detailing and joint placement, designers can minimize cracking due to shrinkage, temperature changes, or applied loads. Additionally, the use of crack control measures such as steel fibers or polypropylene fibers can further enhance the crack resistance of the slab.

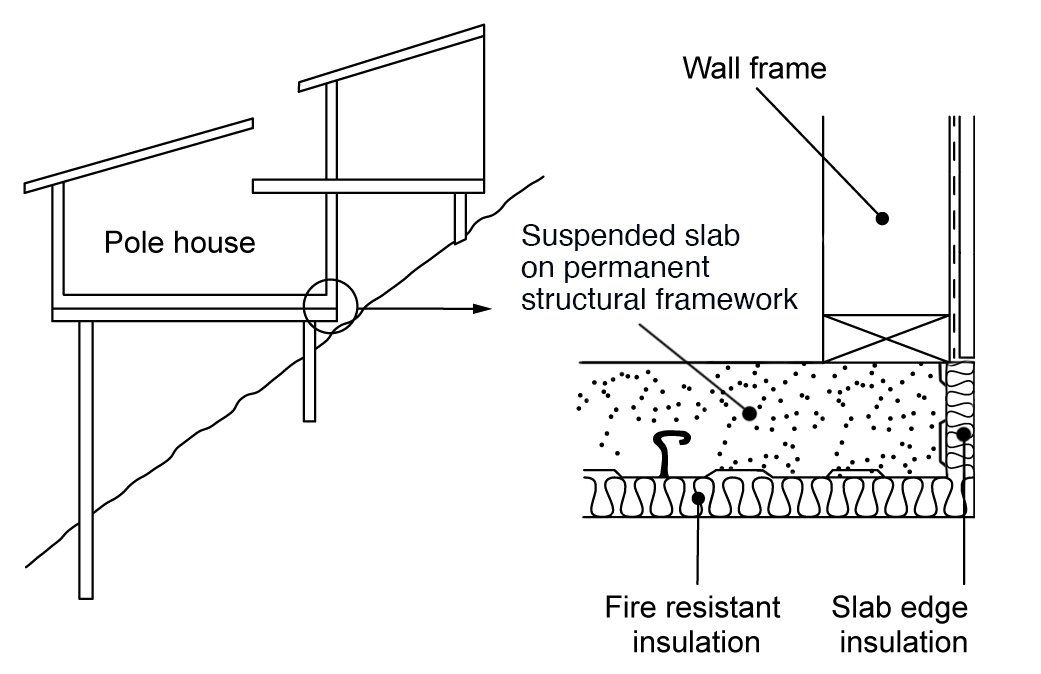

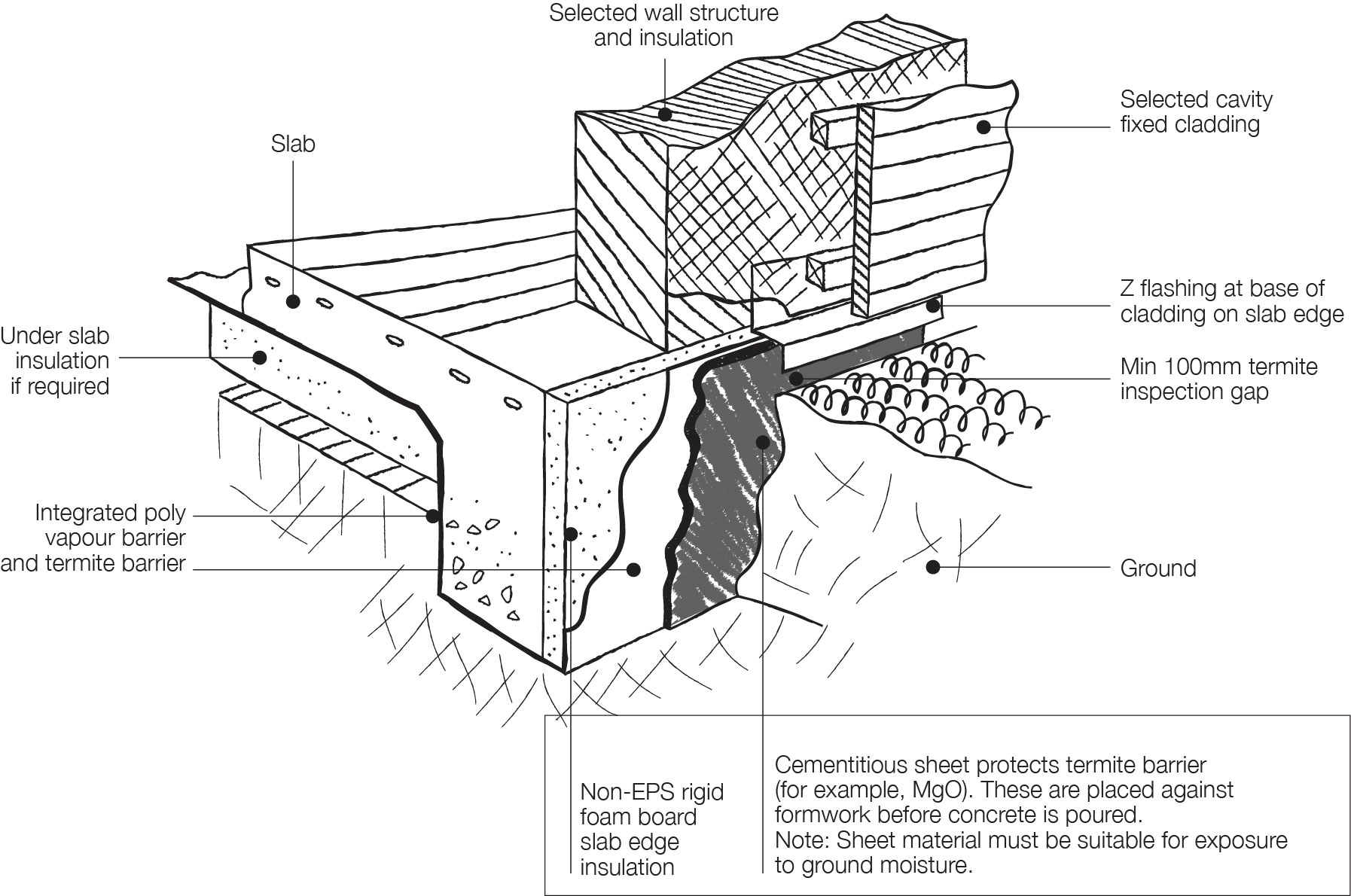

- Thermal Insulation: Thermal insulation is a crucial consideration for suspended concrete floor slabs, especially in buildings where energy efficiency is a priority. Insulating materials can be placed within the slab or below it to minimize heat transfer and reduce energy consumption for heating or cooling. Proper insulation design can also prevent condensation and moisture-related issues.

- Sound Insulation: In many buildings, sound insulation is a vital requirement for suspended concrete floor slabs, particularly in residential or commercial spaces. Various techniques, such as adding resilient layers or installing acoustic underlays, can significantly improve sound insulation properties. Careful consideration should be given to factors like impact noise, airborne sound transmission, and building regulations to achieve the desired sound insulation performance.

Enhancing Strength and Durability in Suspended Concrete Floor Slabs

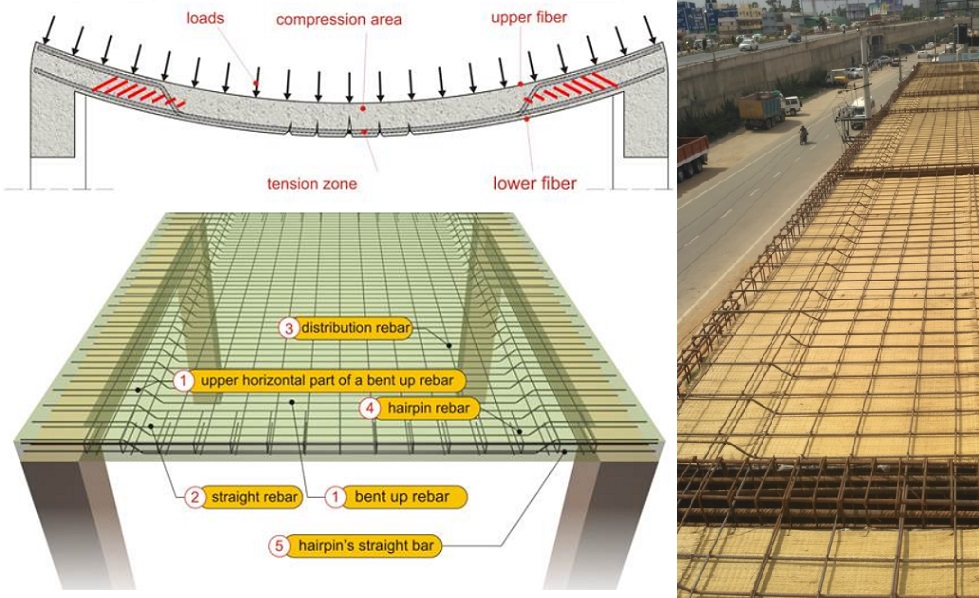

The strength and durability of suspended concrete floor slabs heavily rely on effective reinforcement strategies. Reinforcement plays a crucial role in distributing loads, controlling cracks, and enhancing overall structural performance. We will discuss some key reinforcement strategies that can be employed to enhance the strength and durability of suspended concrete floor slabs.

Reinforcement Types: The choice of reinforcement type is a fundamental consideration in suspended concrete floor slab design. Steel reinforcement, such as rebars or welded wire mesh, is commonly used due to its high tensile strength and compatibility with concrete. Fibre-reinforced polymers (FRP) can also be employed in specific applications to provide corrosion resistance and improve structural performance.

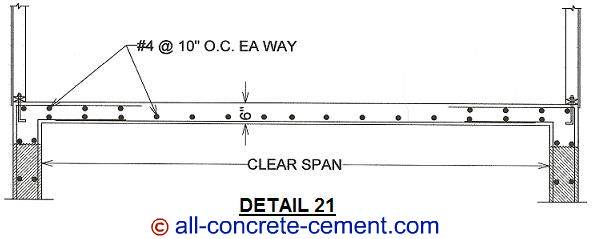

Reinforcement Layout: The layout of reinforcement is crucial for ensuring load distribution and preventing localized stress concentrations in suspended concrete floor slabs. The reinforcement should be strategically placed to resist bending and shear forces, considering factors such as anticipated loads, span lengths, and support conditions. Proper reinforcement detailing, including the arrangement of bars and the use of stirrups, significantly enhances slab strength.

Reinforcement Quantity: Determining the appropriate quantity of reinforcement is essential to achieve the desired strength and durability in suspended concrete floor slabs. This involves calculating the required steel area based on factors like applied loads, concrete strength, and design codes. Adequate reinforcement quantity ensures the slab can withstand anticipated loads without excessive deflection or cracking.

Reinforcement Placement: Proper placement of reinforcement is critical to achieve optimal structural performance. Reinforcement should be positioned accurately within the slab thickness and secured in place to prevent displacement during concrete placement and compaction. Additionally, care should be taken to maintain proper cover thickness to protect the reinforcement from corrosion and ensure long-term durability.

Reinforcement Corrosion Protection: Corrosion of steel reinforcement can significantly compromise the strength and durability of suspended concrete floor slabs. Adequate measures should be taken to protect the reinforcement from corrosive agents, such as moisture or chloride ingress. This can be achieved by using corrosion-resistant reinforcement, applying protective coatings, or ensuring proper concrete quality and cover thickness.

Factors to Keep in Mind for a Successful Suspended Concrete Floor Slab

Designing a successful suspended concrete floor slab involves careful consideration of various factors to ensure structural integrity, functionality, and compliance with building standards. Here are the key design considerations that architects and engineers must keep in mind for a successful suspended concrete floor slab.

Load Requirements: Understanding the anticipated load requirements is essential in designing a suspended concrete floor slab. The loads can vary depending on the building’s function, occupancy, and location. Designers must consider factors such as live loads (e.g., furniture, people), dead loads (e.g., floor finishes, partitions), and any specialized loads (e.g., heavy machinery). By analyzing these loads, designers can determine the appropriate slab thickness and reinforcement requirements.

Span Length and Support Conditions: The span length and support conditions directly impact the design and performance of suspended concrete floor slabs. Longer spans typically require additional reinforcement and thicker slabs to resist deflection. The type of support, whether beams, walls, or columns, also affects load distribution and must be considered in the design process. The structural system should be designed to provide adequate support and ensure the slab remains within acceptable deflection limits.

Building Codes and Regulations: Compliance with local building codes and regulations is crucial when designing suspended concrete floor slabs. Designers must be familiar with the relevant codes and standards governing structural design, fire safety, accessibility, and other applicable regulations. Adhering to these requirements ensures that the floor slab meets safety standards and facilitates the approval process.

Site Conditions and Soil Analysis: Site conditions and soil properties play a significant role in determining the design of suspended concrete floor slabs. Engineers must conduct a thorough geotechnical investigation to assess soil strength, bearing capacity, and potential settlement. This analysis helps determine the appropriate foundation design, slab thickness, and reinforcement requirements to ensure the slab’s stability and long-term performance.

Integration with Other Building Systems: Suspended concrete floor slabs must be seamlessly integrated with other building systems, such as mechanical, electrical, and plumbing installations. Designers must consider the space required for these systems, as well as the coordination of openings and penetrations within the slab. Proper planning and coordination with other disciplines ensure that the design accommodates the necessary infrastructure without compromising the structural integrity of the slab.

Step-by-Step Guide to Building a Suspended Concrete Floor Slab

Constructing a suspended concrete floor slab involves a series of well-executed steps to ensure the proper installation and structural integrity of the slab. Below we provide a step-by-step guide to the construction techniques involved in building a suspended concrete floor slab.

Excavation and Site Preparation: The first step in constructing a suspended concrete floor slab is to excavate the site and prepare the ground. This involves removing the topsoil, compacting the subgrade, and ensuring a level base for the slab. Any necessary drainage systems or utilities should also be installed at this stage.

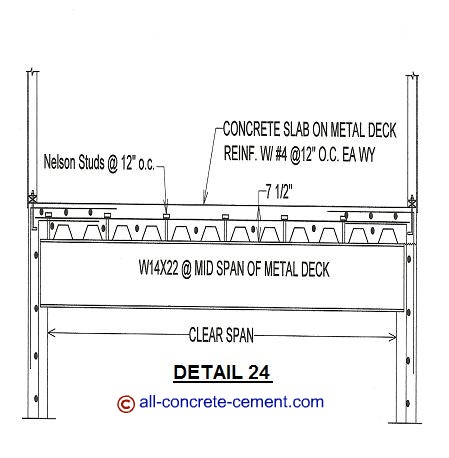

Formwork Installation: Formwork is used to shape and contain the concrete during the pouring and curing process. It is typically made of wood, metal, or plastic and must be properly installed to maintain the desired shape and dimensions of the slab. The formwork should be securely braced and checked for levelness and alignment.

Reinforcement Placement: The next step is to place the reinforcement within the formwork according to the design specifications. This involves laying out the required reinforcement bars or mesh in the correct position and ensuring proper clearance from the formwork. The reinforcement should be supported using chairs or spacers to maintain the desired cover thickness.

Pouring and Compacting the Concrete: Once the reinforcement is in place, the concrete can be poured into the formwork. It is essential to use a high-quality concrete mix with the appropriate strength and workability. The concrete should be poured in layers and compacted using vibrators to remove air voids and ensure proper consolidation. Care should be taken to avoid segregation or excessive bleeding during the pouring process.

Curing and Finishing: After the concrete is poured and consolidated, it must be properly cured to ensure optimal strength development. Curing involves maintaining the appropriate moisture and temperature conditions for the concrete to hydrate and gain strength. Various curing methods, such as wet curing or the use of curing compounds, can be employed. Once the concrete has cured sufficiently, finishing techniques such as troweling or surface treatments can be applied to achieve the desired appearance and texture.

Removal of Formwork and Post-Construction Activities: After the concrete has fully cured, the formwork can be removed. Care should be taken to avoid damaging the edges of the slab during formwork removal. Once the formwork is removed, any necessary post-construction activities such as waterproofing, installation of floor finishes, or utility connections can be carried out.

New Technologies and Design Approaches in Suspended Concrete Floor Slab Construction

As technology advances and new design approaches emerge, the construction industry continually explores innovative solutions for suspended concrete floor slab construction. These advancements aim to enhance efficiency, sustainability, and overall performance. Below are some of the latest technologies and design approaches that are revolutionizing suspended concrete floor slab construction.

Precast Concrete Systems: Precast concrete systems have gained popularity in suspended floor slab construction due to their numerous advantages. Precast concrete floor slabs are manufactured offsite under controlled conditions, ensuring high quality and dimensional accuracy. These precast elements are then transported to the construction site and installed, reducing construction time and minimizing on-site labor. Precast solutions also offer versatility in design and can incorporate features like integrated insulation or pre-installed services.

Composite Steel-Concrete Systems: Composite steel-concrete systems combine the benefits of steel and concrete to create efficient and high-performance suspended floor slabs. These systems typically consist of a steel deck that acts as a formwork during construction and provides reinforcement for the concrete slab. The combined action of steel and concrete results in a lightweight and strong floor system with excellent load-carrying capacity. Composite systems offer rapid construction, flexibility in design, and the ability to achieve long spans.

Voided Slab Systems: Voided slab systems introduce voids or hollow spaces within the concrete slab to reduce the dead load and improve the overall efficiency of the floor system. These voids can be created using various methods, such as using lightweight materials, prefabricated forms, or plastic elements. Voided slab systems reduce the amount of concrete required while maintaining structural integrity. This innovative approach not only saves material and construction costs but also allows for longer spans and improved thermal and acoustic performance.

3D Printing: 3D printing technology is revolutionizing the construction industry, including suspended concrete floor slab construction. By using robotic arms or gantry systems, 3D printers can create complex geometries and intricate reinforcement patterns with precision and speed. This technology enables the construction of customized and highly optimized floor slabs, reducing material waste and labor requirements. 3D printing also offers opportunities for incorporating functional features directly into the slab, such as ducts or channels for utilities.

Sustainable Materials: The focus on sustainability in construction has led to the development and utilization of sustainable materials in suspended concrete floor slabs. Materials such as recycled aggregates, fly ash, or slag can be incorporated into the concrete mix to reduce environmental impact. Additionally, bio-based materials, like engineered wood or bamboo, are being explored as alternatives for floor slab construction. These sustainable materials offer benefits such as lower embodied energy, reduced carbon footprint, and improved indoor air quality.

Pin en my dream

Concrete slab floors YourHome

Building Guidelines Concrete Floors, Slabs

STRUCTURE magazine Creating an Opening in Existing Floors

Forming Concrete Suspended Slabs

Building Guidelines Concrete Floors, Slabs

How to Design One-way Slab as per ACI 318-19? Example Included

Slab On Grade Foundation Design Slab On Grade Design

Suspended Garage Slab from Design-Build Specialists Steel Concepts

Related Posts:

- Applying Concrete Floor Paint

- Non Slip Concrete Floor Sealer

- How To Paint Concrete Garage Floor

- Outdoor Concrete Floor Ideas

- Concrete Floor Covering Ideas

- Cracks In Polished Concrete Floors

- Drylok Concrete Floor Paint Colors

- Polished Concrete Floor Thickness

- Residential Stained Concrete Floors

- Cheap Concrete Floor Finishes