Introduction to Engineered Wood Flooring

Engineered wood flooring has gained immense popularity in recent years due to its durability, aesthetic appeal, and ease of installation. Unlike traditional solid hardwood flooring, which is made from a single piece of wood, engineered wood flooring is constructed using multiple layers of materials. This article will provide a comprehensive overview of engineered wood flooring, its composition, and its advantages.

Composition of Engineered Wood Flooring

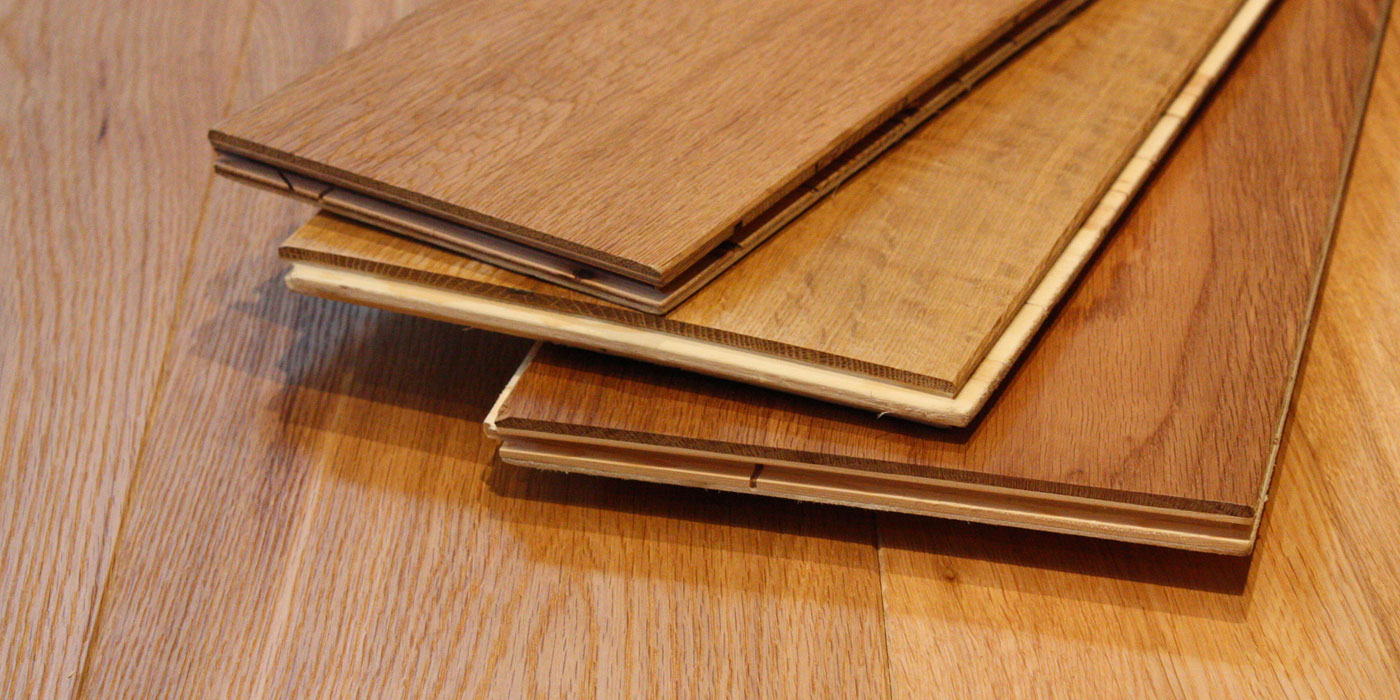

Engineered wood flooring is typically composed of three primary layers: the wear layer, the core layer, and the backing layer. The wear layer is the topmost layer, consisting of a thin veneer of real hardwood that provides the flooring with its beautiful appearance. The core layer, also known as the plywood core, is made up of multiple layers of plywood that are arranged in a cross-grain pattern. This construction adds stability and strength to the flooring. The backing layer, often made of high-density fiberboard (HDF), provides additional support and moisture resistance.

Benefits of Engineered Wood Flooring

One of the key advantages of engineered wood flooring is its dimensional stability. The cross-grain construction of the plywood core helps to minimize the expansion and contraction of the flooring due to changes in humidity and temperature. This makes engineered wood flooring a great choice for areas with fluctuating moisture levels, such as basements or kitchens.

Another benefit of engineered wood flooring is its versatility. It can be installed in various settings, including above, on, or below grade. Additionally, engineered wood flooring can be installed using different methods, such as floating, glue-down, or nail-down, providing flexibility to suit different installation requirements and preferences.

Furthermore, engineered wood flooring is an environmentally friendly choice. By using a thin veneer of hardwood, engineered wood flooring maximizes the use of natural resources. It also reduces waste by utilizing less high-quality hardwood compared to solid wood flooring.

In terms of aesthetics, engineered wood flooring offers a wide range of options. The veneer layer can be made from different wood species, providing various colors, grains, and finishes to suit different interior design styles. Whether you prefer a rustic oak look or a sleek and modern maple finish, engineered wood flooring can cater to your specific taste and preferences.

Engineered wood flooring is a durable, versatile, and environmentally friendly flooring option. Its composition, consisting of a wear layer, plywood core, and backing layer, ensures stability and resistance to moisture. With its wide range of styles and installation methods, engineered wood flooring is an excellent choice for both residential and commercial spaces.

Plywood Core: The Foundation of Engineered Wood Flooring

The plywood core is a crucial component of engineered wood flooring. It serves as the foundation that provides stability, strength, and dimensional stability to the flooring. Let’s discuss the details of the plywood core and its significance in engineered wood flooring.

Construction of the Plywood Core

The plywood core is typically constructed using multiple layers of plywood that are stacked and bonded together. The layers are arranged in a cross-grain pattern, with each layer’s grain direction perpendicular to the adjacent layer. This construction technique enhances the flooring’s stability and prevents warping or cupping.

Advantages of the Plywood Core

The cross-grain construction of the plywood core is what sets engineered wood flooring apart from solid hardwood flooring. This construction method counteracts the natural tendency of wood to expand and contract with changes in humidity and temperature. By arranging the layers perpendicular to each other, the plywood core helps to distribute stress evenly, reducing the risk of warping or buckling.

Additionally, the plywood core enhances the strength of the flooring. The multiple layers of plywood provide excellent structural integrity, making engineered wood flooring highly resistant to heavy foot traffic, impacts, and other forms of wear and tear. This durability ensures that the flooring maintains its quality and appearance for years to come.

Moisture Resistance

One of the significant advantages of the plywood core is its moisture resistance. Unlike solid hardwood flooring, which is prone to warping and swelling when exposed to moisture, engineered wood flooring with a plywood core is more resistant to these issues. The cross-grain pattern of the plywood layers helps to minimize the effects of moisture by allowing the wood to expand and contract evenly.

Sustainability

The use of plywood in the core of engineered wood flooring contributes to its sustainability. Plywood is made from thin layers of wood veneer that are bonded together, maximizing the use of natural resources. Additionally, plywood is often made from fast-growing tree species, reducing the impact on old-growth forests. Choosing engineered wood flooring with a plywood core helps to promote sustainable practices in the flooring industry.

Veneer: The Beautiful Face of Engineered Wood Flooring

The veneer layer of engineered wood flooring is responsible for its stunning appearance. It showcases the natural beauty of real hardwood, allowing homeowners to enjoy the look and feel of solid wood flooring while benefiting from the enhanced stability and versatility of engineered wood. Let’s talk about the details of the veneer layer and its role in creating the aesthetic appeal of engineered wood flooring.

Selection of Veneer

The veneer layer is typically made from a thin slice of real hardwood, such as oak, maple, or walnut. The selection of the veneer is crucial as it determines the color, grain pattern, and overall look of the flooring. Manufacturers carefully choose high-quality hardwood species and consider factors such as durability, sustainability, and aesthetic appeal.

Enhancing Natural Beauty

The veneer layer is responsible for showcasing the unique characteristics and natural beauty of the chosen hardwood species. It highlights the grain patterns, knots, and color variations that are inherent in the wood, giving the flooring a distinctive and authentic appearance. Whether you prefer a rustic, distressed look or a sleek, contemporary finish, the veneer layer can be customized to suit your preferences.

Thickness and Wear Layer

The thickness of the veneer layer can vary depending on the manufacturer and the specific product. Thicker veneer layers provide more durability and allow for future refinishing if needed. It is important to consider the wear layer, which is the topmost part of the veneer layer, as it determines the longevity of the flooring. A thicker wear layer can withstand more wear and tear, making it suitable for high-traffic areas.

Finishing Options

The veneer layer can be treated with various finishes to enhance its appearance and protect the wood. Common finishes include oil-based finishes, water-based finishes, and UV-cured finishes. These finishes can offer different levels of sheen, from matte to glossy, and can enhance the natural color and grain pattern of the wood. Finishing options also provide additional protection against stains, scratches, and moisture.

Durability and Maintenance

The veneer layer of engineered wood flooring is designed to withstand daily wear and tear. It is important to note that the durability of the flooring depends not only on the veneer layer but also on the overall construction and quality of the product. Regular maintenance, such as sweeping, vacuuming, and occasional damp mopping, helps to preserve the beauty and performance of the veneer layer.

Adhesives and Binders: Holding it All Together

Adhesives and binders are essential components in the construction of engineered wood flooring. They play a crucial role in holding the various layers together, ensuring the stability and durability of the flooring. Let’s explore the importance of adhesives and binders in engineered wood flooring and their contribution to its overall performance.

Types of Adhesives Used

There are different types of adhesives used in the manufacturing of engineered wood flooring. One common type is polyvinyl acetate (PVA) adhesive, which is known for its strong bonding properties. PVA adhesives are water-based and provide excellent adhesion between the layers of the flooring. Another type is urea-formaldehyde adhesive, which is a synthetic resin adhesive that offers high strength and durability.

Bonding Process

The bonding process involves applying the adhesive between the layers of the engineered wood flooring. The layers, including the veneer, plywood core, and backing layer, are stacked and pressed together under high pressure to ensure a strong and secure bond. The adhesive penetrates the wood fibers, creating a solid connection that holds the layers together.

Stability and Structural Integrity

The use of high-quality adhesives and binders in engineered wood flooring ensures stability and structural integrity. The strong bonding between the layers prevents the flooring from warping, cupping, or delaminating. This stability allows the flooring to withstand heavy foot traffic, furniture movement, and other stresses, ensuring its longevity and performance over time.

Environmental Considerations

In recent years, there has been a growing emphasis on using environmentally friendly adhesives in the production of engineered wood flooring. Low or zero-volatile organic compound (VOC) adhesives are becoming more popular as they have reduced emissions and contribute to better indoor air quality. Manufacturers are increasingly adopting eco-friendly adhesive options to meet sustainability goals and cater to environmentally conscious consumers.

Compliance with Standards and Regulations

The use of adhesives and binders in engineered wood flooring must comply with specific standards and regulations. For example, certain countries may have regulations regarding formaldehyde emissions from adhesives. Manufacturers need to ensure that their products meet the required standards to ensure consumer safety and environmental responsibility.

Finishes and Coatings: Protecting and Enhancing Engineered Wood Flooring

Finishes and coatings are essential components of engineered wood flooring that serve to protect the surface of the flooring and enhance its appearance. In this article, we will explore the importance of finishes and coatings in engineered wood flooring and how they contribute to its durability and visual appeal.

Protective Layer

Finishes and coatings create a protective layer on the surface of engineered wood flooring, shielding it from daily wear and tear. This layer acts as a barrier against scratches, stains, moisture, and UV rays, prolonging the lifespan of the flooring. By preventing damage, finishes and coatings help maintain the beauty and integrity of the wood for years to come.

Types of Finishes

There are various types of finishes and coatings available for engineered wood flooring. One common type is polyurethane, which provides a durable and long-lasting protective layer. Polyurethane finishes come in different sheens, such as matte, satin, semi-gloss, and high-gloss, allowing homeowners to choose the desired level of shine. Another popular option is an oil finish, which penetrates the wood fibers, enhancing its natural beauty while providing protection.

Enhancing Aesthetic Appeal

Finishes and coatings not only protect the surface of the flooring but also enhance its aesthetic appeal. They can bring out the natural color and grain patterns of the wood, creating a vibrant appearance. Additionally, finishes and coatings can add depth and luster to the flooring, giving it a polished and refined look. Whether you prefer a warm and rustic feel or a sleek and modern aesthetic, the right finish can complement your design vision.

Maintenance and Cleaning

Finishes and coatings make engineered wood flooring easier to clean and maintain. The protective layer prevents dirt, spills, and stains from penetrating the wood, making it simple to wipe away any messes. Regular cleaning, such as sweeping, vacuuming, and occasional damp mopping, is typically all that is needed to keep the flooring looking its best. Additionally, finishes and coatings can help reduce the need for refinishing or sanding the flooring over time.

Environmental Considerations

When choosing finishes and coatings for engineered wood flooring, it is important to consider their environmental impact. Water-based finishes are often preferred as they have lower VOC emissions compared to solvent-based finishes. Low VOC options contribute to better indoor air quality and promote a healthier living environment. Many manufacturers offer environmentally friendly finishes and coatings that meet strict sustainability standards.

All About Engineered Wood Flooring

Engineered Wood Flooring Signature Home Inspection

What is engineered wood flooring?

What is Engineered Hardwood Flooring?

Hardwood Vs. Engineered Wood Flooring u2013 Which Is Best For You

Related Posts: