As an expert in structural design, I am excited to share with you the importance of wood floor truss design. Wood floor trusses play a crucial role in providing a solid foundation and structural support for residential and commercial buildings. I will provide a concise and informative overview of wood floor truss design, highlighting its benefits and answering common questions to help you make informed decisions.

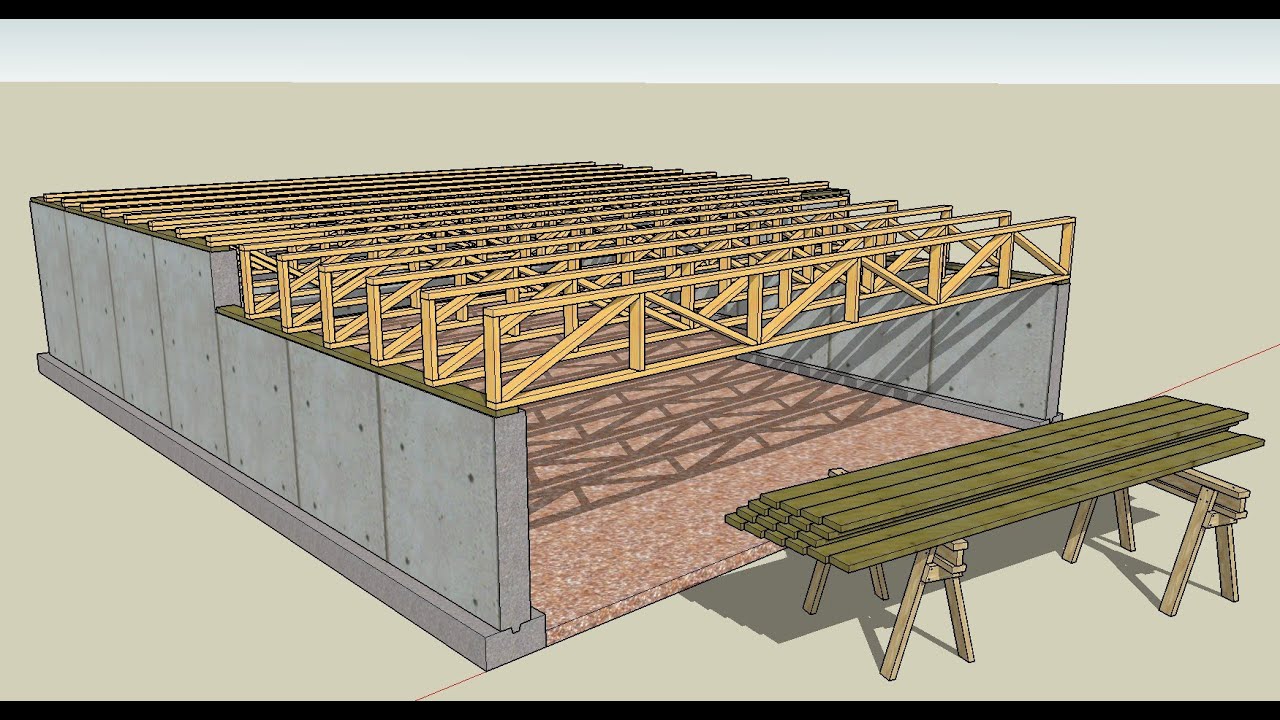

Wood floor trusses are engineered components designed to efficiently carry the load of a floor system, transferring it to the supporting walls or beams. These trusses are constructed using high-quality wood, such as spruce, pine, or fir, and are engineered to meet specific load requirements. The design of wood floor trusses offers several advantages over traditional solid wood joist systems.

One of the key benefits of wood floor trusses is their strength and load-carrying capacity. Trusses are designed to distribute the load evenly across the entire span, providing enhanced structural integrity and minimizing the risk of sagging or excessive deflection. This ensures a solid and stable floor system that can support the weight of furniture, occupants, and other live loads.

Another advantage of wood floor truss design is its versatility. Trusses can be customized to accommodate various floor layouts, including open-concept spaces, irregular shapes, and long spans. The flexibility in design allows for greater architectural freedom and creativity in building design while still maintaining the necessary structural support.

Wood floor trusses are also known for their cost-effectiveness. Trusses require less lumber than traditional solid wood joist systems, reducing material costs. Additionally, the prefabricated nature of trusses speeds up the construction process, reducing labor costs and overall project timelines. This makes wood floor trusses a practical and efficient choice for both residential and commercial construction projects.

Wood floor truss design offers numerous benefits, including strength, versatility, and cost-effectiveness. These engineered components provide a solid foundation for residential and commercial buildings, ensuring structural integrity and load-carrying capacity. By understanding the advantages of wood floor trusses and addressing common questions, you can confidently incorporate them into your construction projects, knowing that you are making an informed decision for a reliable and efficient floor system.

Can wood floor trusses be used in all types of construction?

Wood floor trusses are commonly used in residential and light commercial construction. Depending on the specific load requirements and design considerations, they can be employed in single-family homes, multi-story buildings, and even industrial structures. It’s important to consult with a structural engineer or a qualified professional to determine the suitability of wood floor trusses for your construction project.

Are wood floor trusses fire-resistant?

Wood floor trusses can be designed to meet fire-resistant requirements. The fire performance of wood floor trusses can be enhanced by incorporating fire-resistant treatments or using fire-rated materials, such as gypsum board or intumescent coatings. It’s crucial to adhere to local building codes and regulations regarding fire safety and consult with professionals to ensure compliance.

Can plumbing and electrical systems be integrated into wood floor trusses?

Yes, plumbing and electrical systems can be integrated into wood floor trusses. Openings or chases can be incorporated into the truss design to accommodate plumbing pipes, electrical conduits, or HVAC ductwork. Proper coordination between the structural engineer and the mechanical and electrical trades is necessary to ensure that the trusses maintain their structural integrity while allowing for the required service penetrations.

Are wood floor trusses prone to insect infestation or rot?

Like any wood-based construction material, wood floor trusses are susceptible to insect infestation and rot if not properly protected. To mitigate these risks, the wood used for truss construction should be treated with preservatives to resist insect attacks and decay. Additionally, proper ventilation and moisture control measures during construction and throughout the life of the building are crucial in preventing moisture-related issues that can lead to rot.

How long does it take to design and fabricate wood floor trusses?

The design and fabrication timeline for wood floor trusses can vary depending on the project’s complexity, the structure’s size, and the availability of design information. Typically, the design process, including engineering calculations and truss layout, can take several weeks. The fabrication and delivery time can range from a few weeks to a couple of months, depending on the workload of the truss manufacturer and the project schedule.

FLOOR-TRUSS Floor System – MiTek Canada

Floor Trusses u2013 Anderson Truss Company

Why you should consider floor trusses instead of joists for the

Charlotte Floor Trusses, Wooden Floor Truss Design All Truss

Installing floor trusses (and trusses vs. joists) – NewlyWoodwards

RedBuilt Open-Web Truss – Roof Trusses and Floor Trusses

Part 7 How to Draw Floor Trusses and Foundations

Floor Truss Design – Rigidply Rafters

Floor Truss Advantage with Midland Truss, Inc – Floor u0026 Roof Truss

Related Posts:

- Real Wood Flooring For Kitchens

- Wood Flooring Design Tips

- Grey Wood Flooring Bathroom

- Rustic White Wood Flooring

- Wide Plank Pine Wood Flooring

- Blue Grey Wood Flooring

- Light Wood Flooring Ideas

- Distressed Wood Flooring

- Acacia Wood Flooring

- Wood Flooring Design