Understanding Anti Static Epoxy Flooring

Anti static epoxy flooring is a specialized type of flooring that is designed to control static electricity. It is commonly used in environments where static electricity can cause damage to sensitive equipment or pose a safety hazard. let’s talk about the basics of anti-static epoxy flooring, its composition, and how it works.

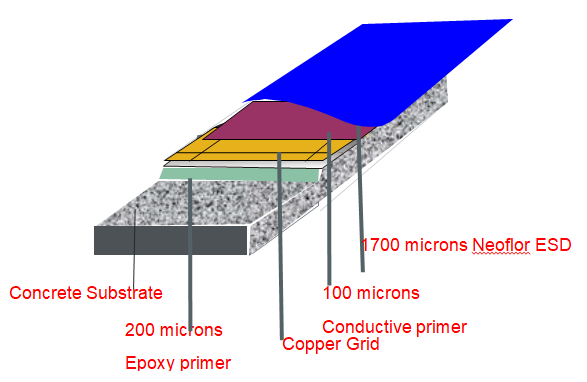

- What is Anti Static Epoxy Flooring? Anti-static epoxy flooring is a type of flooring that contains conductive materials to dissipate static electricity. It is typically composed of epoxy resin mixed with conductive additives such as carbon fibers or metallic particles. This unique composition allows the flooring to provide a path for the static charge to safely discharge, preventing potentially harmful electrostatic discharge (ESD).

- How does Anti Static Epoxy Flooring Work? Anti static epoxy flooring works by creating a conductive network throughout the floor, which allows static electricity to flow safely to the ground. The conductive additives in the flooring material help to dissipate any static charge generated by people or equipment moving across its surface.

- Why is Anti Static Epoxy Flooring Important? Static electricity can cause significant damage to sensitive electronic components and equipment. In industries such as electronics manufacturing, pharmaceuticals, laboratories, and data centers, where static-sensitive devices are present, it is crucial to have anti-static measures in place. Anti static epoxy flooring helps to prevent static build-up, ensuring the safety and integrity of sensitive equipment.

- Types of Anti-Static Epoxy Flooring: There are two main types of anti-static epoxy flooring: static dissipative and conductive. Static dissipative flooring has a higher resistance and is suitable for environments where static discharge needs to be controlled but not eliminated completely. Conductive flooring, on the other hand, has a lower resistance and is used in areas where static electricity must be eliminated entirely, such as explosive manufacturing facilities.

The Benefits of Anti-Static Epoxy Flooring

Anti static epoxy flooring offers numerous benefits, particularly in environments where static electricity poses a risk to sensitive equipment or products. Below are the advantages of using anti-static epoxy flooring and how it contributes to protecting sensitive environments.

- Electrostatic Discharge Protection: One of the primary benefits of anti-static epoxy flooring is its ability to provide protection against electrostatic discharge (ESD). By dissipating static electricity, the flooring prevents ESD events that can damage electronic components or cause explosions in volatile environments.

- Equipment and Product Safety: Static electricity can be harmful to sensitive electronic equipment, such as computer servers, circuit boards, and microchips. Anti-static epoxy flooring helps to safeguard these devices by minimizing the risk of static discharge, ensuring their proper functioning and longevity. Additionally, in industries like pharmaceuticals and manufacturing, where static-sensitive products are handled, anti static flooring prevents product damage and quality issues.

- Enhanced Safety for Personnel: In environments where static electricity is present, there is a risk of personnel experiencing static shocks. Anti static epoxy flooring reduces the likelihood of these shocks, enhancing the safety and comfort of employees. By minimizing static-related accidents, such as slips or falls caused by static charge accumulation, the flooring contributes to a safer working environment.

- Chemical Resistance and Durability: Anti-static epoxy flooring is known for its chemical resistance and durability. It can withstand exposure to various chemicals, making it suitable for industries where corrosive substances are used. Additionally, the flooring is highly durable, with excellent resistance to wear, impact, and abrasion, ensuring a longer lifespan and reducing the need for frequent repairs or replacements.

- Easy Maintenance and Cleanliness: Anti static epoxy flooring is easy to clean and maintain, making it a practical choice for many industries. The smooth, seamless surface of the flooring allows for effortless cleaning and eliminates the possibility of dirt or contaminants accumulating in joints or seams. Regular maintenance, such as routine cleaning and occasional reapplication of anti-static coatings, ensures the flooring’s optimal performance.

Installation and Maintenance of Anti-Static Epoxy Flooring

Proper installation and regular maintenance are essential for ensuring the effectiveness and longevity of anti static epoxy flooring. In this article, we will discuss best practices for the installation and maintenance of anti static epoxy flooring.

Installation Best Practices:

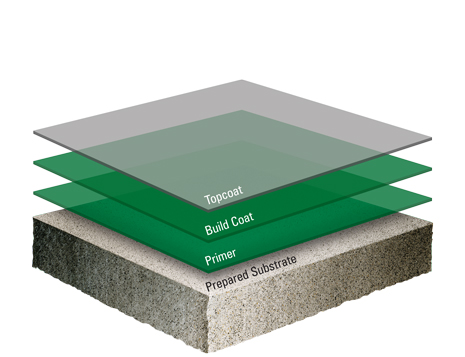

- Surface Preparation: The success of any flooring installation relies heavily on surface preparation. Before applying anti static epoxy flooring, ensure that the substrate is clean, dry, and free from any contaminants or loose materials. Proper surface preparation includes cleaning, repairing any cracks or unevenness, and applying a primer if necessary.

- Proper Mixing and Application: Follow the manufacturer’s instructions for mixing the epoxy resin and conductive additives. Thoroughly mix the components to achieve a uniform consistency. Apply the epoxy flooring evenly and at the recommended thickness, using the appropriate tools and techniques.

- Curing Time: Allow the flooring sufficient time to cure before exposing it to heavy traffic or placing equipment on it. Curing times may vary depending on the specific product used, so it’s crucial to follow the manufacturer’s guidelines.

Maintenance Best Practices:

- Regular Cleaning: Clean the anti static epoxy flooring regularly using a mild detergent and water. Avoid using abrasive cleaners or harsh chemicals that can damage the flooring. Sweep or vacuum the floor daily to remove dirt and debris that can scratch the surface.

- Preventive Measures: Place walk-off mats at entryways to minimize the transfer of dirt and contaminants onto the flooring. Install proper footwear policies, such as requiring the use of anti static footwear or heel straps, to reduce static build-up and potential damage to the floor.

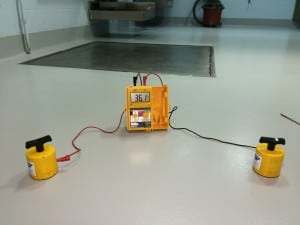

- Periodic Inspections: Conduct regular inspections to identify any signs of wear, damage, or deterioration. Address any issues promptly to prevent further damage and maintain the flooring’s static dissipative properties. Consider scheduling professional inspections and maintenance to ensure optimal performance.

Safety Considerations:

- Follow Safety Guidelines: During installation and maintenance, adhere to safety guidelines and use appropriate personal protective equipment (PPE) to protect against potential hazards. This includes wearing gloves, safety glasses, and respirators as necessary.

- Static Control Measures: Implement additional static control measures, such as grounding systems, wrist straps, and ionizers, to complement the anti static epoxy flooring. These measures further enhance static control and prevent electrostatic discharge in sensitive environments.

Industries that Benefit from Anti-Static Epoxy Flooring

Anti static epoxy flooring finds applications in various industries where static electricity poses risks to equipment, products, or personnel. In this article, we will provide a comprehensive guide to industries that benefit from the use of anti-static epoxy flooring.

Electronics Manufacturing: The electronics manufacturing industry extensively relies on anti static measures to protect sensitive electronic components from static discharge. Anti-static epoxy flooring ensures a static-free environment, preventing damage to delicate electronic devices during production, assembly, and testing processes.

Pharmaceuticals and Laboratories: Pharmaceutical manufacturing facilities and laboratory environments require static control to maintain the integrity and quality of their products. Anti-static epoxy flooring prevents static build-up, reducing the risk of contamination or damage to sensitive pharmaceutical formulations and laboratory experiments.

Data Centers and Server Rooms: Data centers and server rooms house critical IT infrastructure that must be protected from static electricity. Anti static epoxy flooring ensures a controlled environment, minimizing the risk of electrostatic discharge that can damage servers, network equipment, and data storage devices.

Automotive and Aerospace: In the automotive and aerospace industries, static electricity can pose risks during the manufacturing and assembly of electronic components, fuel handling, and paint application processes. Anti-static epoxy flooring prevents static build-up, protecting personnel, equipment, and materials from potential hazards.

Explosive Manufacturing: Explosive manufacturing facilities require stringent static control measures to prevent accidental explosions. Conductive anti static epoxy flooring eliminates static electricity, ensuring a safe working environment where static discharge does not ignite explosive materials.

Cleanrooms and Semiconductor Manufacturing: Cleanrooms and semiconductor manufacturing facilities demand high levels of cleanliness and static control. Anti static epoxy flooring helps maintain the required clean environment and prevents static discharge, safeguarding the sensitive processes involved in semiconductor fabrication.

Choosing the Right Solution for Your Needs

When selecting anti static epoxy flooring, it is important to consider various factors to determine the most suitable solution for your specific needs. In this article, we will compare different types of anti-static epoxy flooring and highlight key factors to consider when making a choice.

Static Dissipative vs. Conductive Flooring: Static dissipative flooring has a higher electrical resistance and is suitable for environments where static discharge needs to be controlled but not eliminated completely. Conductive flooring, on the other hand, has a lower resistance and is used in areas where static electricity must be eliminated entirely. Consider the level of static control required in your environment when choosing between these two options.

Performance Specifications: Evaluate the performance specifications of different anti-static epoxy flooring options, such as their electrical resistance, durability, chemical resistance, and cleanability. These specifications will determine how well the flooring will meet your specific needs and the level of maintenance required.

Compliance with Industry Standards: Ensure that the anti static epoxy flooring you choose complies with relevant industry standards and regulations. In industries such as electronics manufacturing or pharmaceuticals, there may be specific requirements for static control measures. Compliance with these standards will help ensure the flooring meets the necessary criteria for your industry.

Cost Considerations: Compare the costs associated with different anti static epoxy flooring options, including installation, maintenance, and potential downtime during installation. Consider the long-term benefits and potential cost savings from reduced equipment damage, enhanced safety, and lower maintenance requirements.

Expert Consultation: Seek expert advice from flooring professionals, architects, or engineers specializing in static control solutions. They can provide valuable insights and recommendations based on their expertise and industry experience, helping you make an informed decision.

Flowcrete’s Robust and Decorative Anti-static Epoxy Resin Floor

Flowcretes Robust and Decorative Anti-static Epoxy Resin Floor

ESD Epoxy Flooring: Frequently Asked Questions EP Floors Corp.

EPOXY ANTISTATIC PRIMER

Anti Static Epoxy Flooring epoxy floor coating anti static

Related Posts:

- Epoxy Gloss Floor Paint

- Epoxy Concrete Floor Covering

- Thick Epoxy Floor Coating

- Epoxy Paint Floor Finish

- Epoxy Floor Coating For Basement

- White Metallic Epoxy Floor

- Metallic Epoxy Floor Installation

- Red Epoxy Floor

- Clear Epoxy Shower Floor

- Office Epoxy Flooring