Introduction to Composite Steel and Concrete Floor Construction

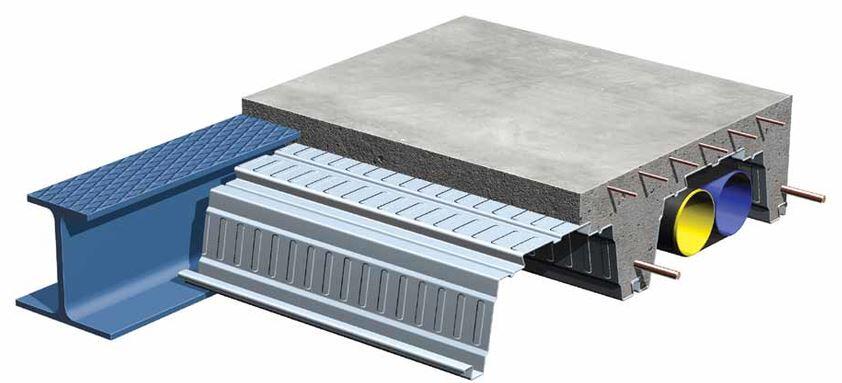

Composite steel and concrete floor construction is a widely used method in the construction industry that combines the strength and durability of steel with the versatility and fire-resistant properties of concrete. This construction technique involves the integration of steel beams or joists with concrete slabs to create a composite floor system. The combination of these materials allows for efficient load transfer, improved structural performance, and enhanced fire resistance.

One of the key advantages of composite steel and concrete floor construction is its ability to withstand heavy loads. The steel beams or joists act as the primary load-bearing members, while the concrete slab provides additional strength and stiffness. This combination ensures that the floor system can support large live loads, making it suitable for various applications, including commercial buildings, industrial facilities, and multi-story residential structures.

Another benefit of composite steel and concrete floor construction is its fire-resistant properties. Concrete is inherently fire-resistant, providing a protective layer that prevents the spread of fire. When combined with steel, which has a high melting point, the composite floor system can withstand high temperatures and maintain its structural integrity, allowing occupants more time to evacuate in case of a fire emergency.

Furthermore, composite steel and concrete floor construction offers significant design flexibility. The use of steel beams or joists allows for longer spans between supports, reducing the need for additional columns or walls. This open floor plan enhances the overall aesthetic appeal of the space and provides more opportunities for creative interior design.

Benefits of Composite Steel and Concrete Floor Construction

Composite steel and concrete floor construction offers numerous benefits that make it a preferred choice for architects, engineers, and contractors. Some of the key advantages of this construction technique are highlighted below:

Enhanced Structural Performance: The combination of steel and concrete in a composite floor system results in enhanced structural performance. The steel beams or joists provide excellent load-bearing capacity, while the concrete slab adds stiffness and strength, resulting in a floor system capable of supporting heavy loads without excessive deflection.

Fire Resistance: Fire safety is a crucial consideration in building design. Composite steel and concrete floor construction offers high fire resistance due to the inherent properties of concrete. In the event of a fire, the concrete slab acts as a protective barrier, preventing the spread of flames and providing occupants with valuable time to evacuate the building safely.

Design Flexibility: With composite steel and concrete floor construction, architects and designers have increased flexibility in creating open and spacious interiors. The use of steel beams or joists allows for longer spans between supports, reducing the need for additional columns or walls. This results in more versatile floor layouts and the ability to accommodate a wide range of architectural designs.

Cost Efficiency: Composite steel and concrete floor construction can be cost-effective in the long run. The durability and strength of the materials used ensure a longer lifespan for the floor system, reducing the need for frequent repairs or replacements. Additionally, the design flexibility and open floor plans can lead to potential cost savings in terms of material usage and construction time.

Sustainability: Composite steel and concrete floor construction aligns with sustainable building practices. Concrete is a widely available and recyclable material, reducing the environmental impact. Furthermore, the long lifespan and durability of composite floor systems contribute to the overall sustainability of the building, reducing the need for resource-intensive renovations or replacements.

Design Considerations for Composite Steel and Concrete Floor Construction

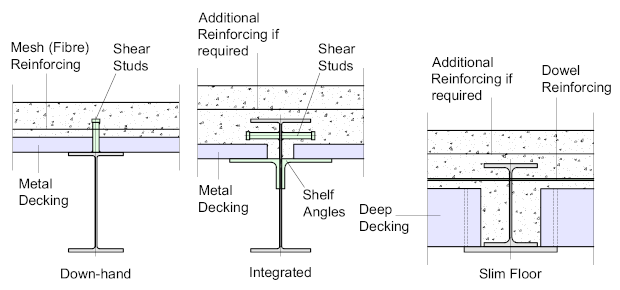

Designing a composite steel and concrete floor system requires careful consideration of various factors to ensure optimal performance and structural integrity. Here are some key design considerations to keep in mind:

Load Capacity: Determining the load capacity is essential for designing a composite floor system. Consider the intended use of the structure and calculate the live loads, dead loads, and any additional loads that the floor system will need to support. This information will guide the selection of appropriate steel beams or joists and the thickness of the concrete slab.

Span Length: The span length refers to the distance between supports or columns. Longer spans can offer more flexibility in the interior layout and reduce the need for additional structural elements. However, longer spans may require larger steel sections or thicker concrete slabs to ensure adequate load-bearing capacity. Consider the balance between span length, structural requirements, and cost-effectiveness.

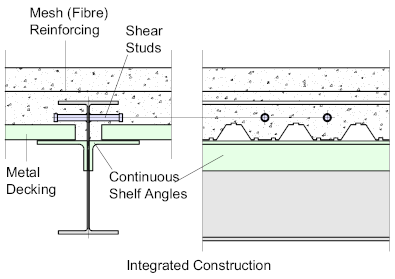

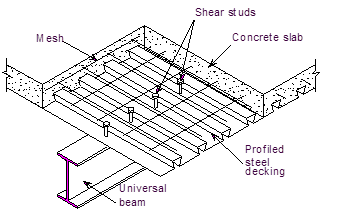

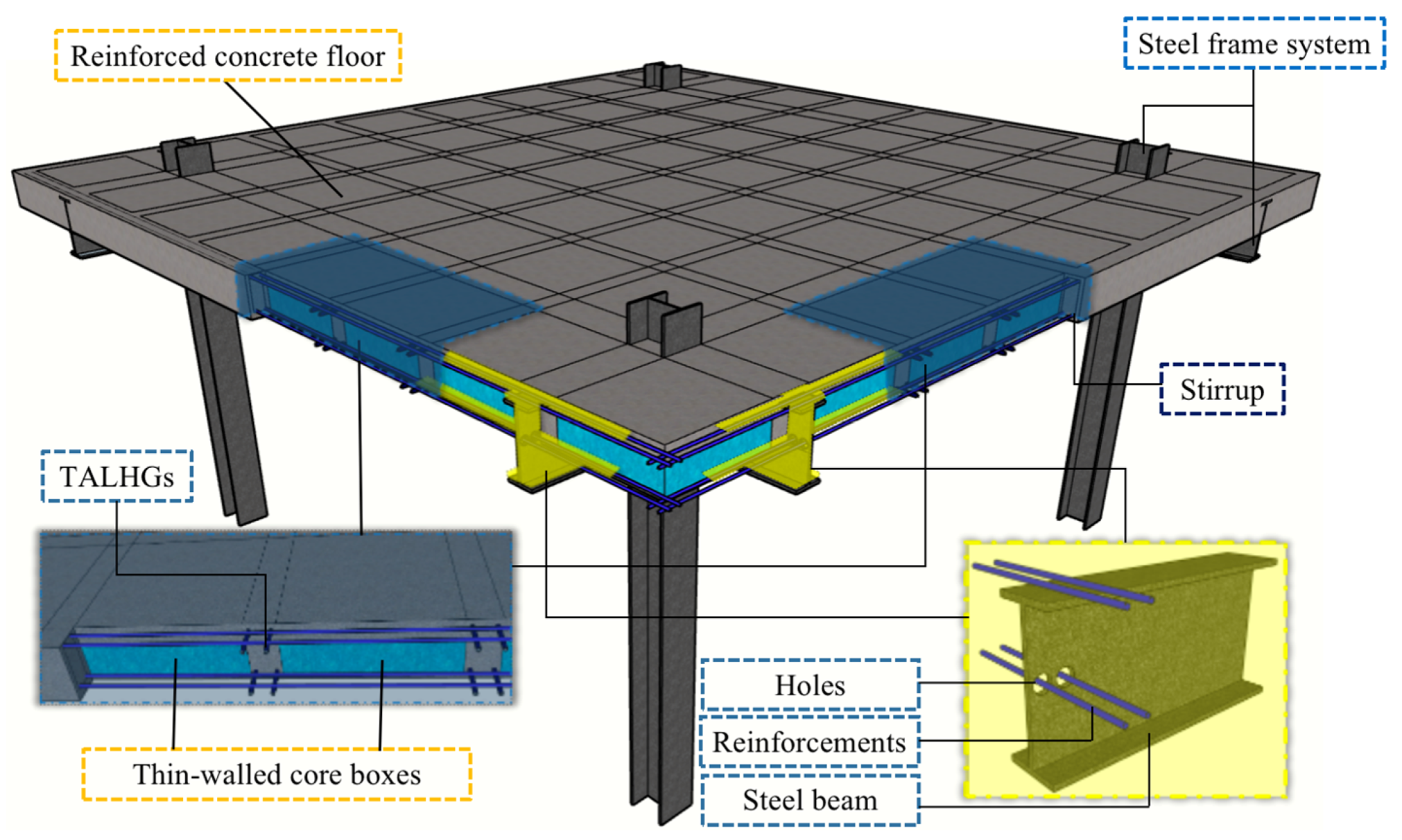

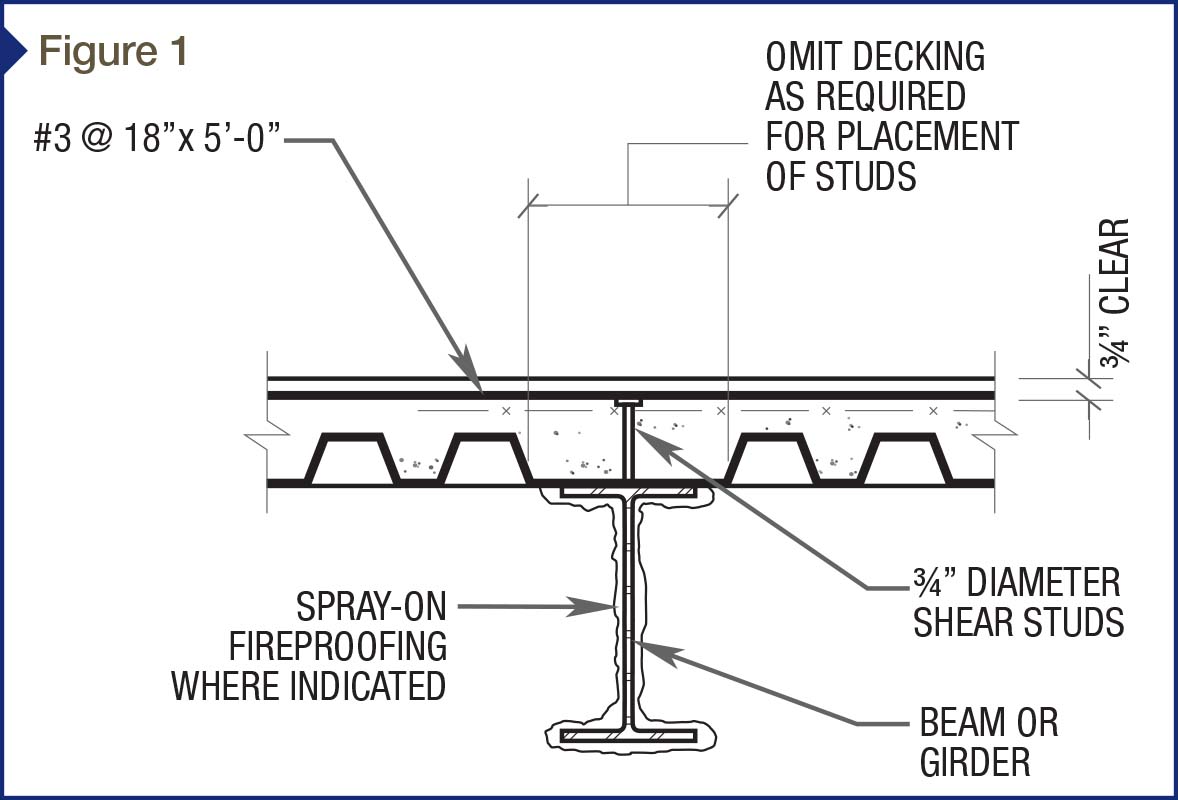

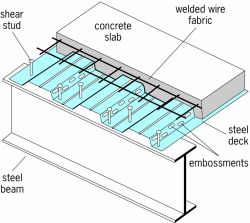

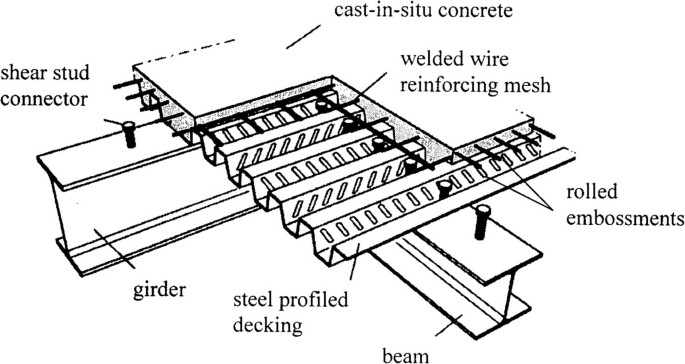

Composite Action: Achieving composite action between the steel beams or joists and the concrete slab is crucial for optimal load transfer. Proper shear connectors, such as headed studs or shear connectors welded to the steel beams, are necessary to ensure the effective transfer of forces between the steel and concrete components.

Fire Resistance: Incorporating fire-resistant measures into the design is essential to ensure the safety of occupants. Consider the required fire rating for the floor system and choose appropriate materials and construction techniques. Fire-resistant coatings or fireproofing materials may be necessary to protect the steel components and enhance the overall fire resistance of the composite floor system.

Acoustic Performance: Composite steel and concrete floor systems can provide good acoustic performance by reducing sound transmission between floors. Consider incorporating sound-absorbing materials, resilient layers, or suspended ceiling systems to improve the acoustic properties of the floor system.

Deflection and Vibrations: Evaluate the deflection and vibration characteristics of the composite floor system to ensure occupant comfort and structural stability. Consider factors such as floor finishes, floor loading, and the need for specific deflection criteria. Structural design techniques, such as adding additional steel members or increasing the thickness of the concrete slab, may be necessary to control deflection and vibrations.

Construction Process for Composite Steel and Concrete Floor Systems

The construction process for composite steel and concrete floor systems involves several key steps to ensure the proper integration of steel and concrete components. Here is an overview of the typical construction process:

Structural Design and Planning: The first step is to develop a detailed structural design for the composite floor system. This includes determining the dimensions and specifications of the steel beams or joists and the thickness and reinforcement requirements of the concrete slab. The design should consider the load capacity, span length, fire resistance, and other design considerations discussed earlier.

Steel Beam or Joist Installation: Once the design is finalized, the steel beams or joists are installed. These are typically fabricated off-site and delivered to the construction site. The beams are positioned and secured in place according to the structural design, ensuring proper alignment and connection to the supporting columns or walls.

Shear Connector Installation: To achieve composite action between the steel beams or joists and the concrete slab, shear connectors are installed. These connectors, such as headed studs or shear connectors welded to the steel beams, provide the necessary bonding between the steel and concrete components. The spacing and type of shear connectors should follow the design specifications.

Formwork Installation: Formwork is then installed to create the mold for the concrete slab. This includes placing temporary supports, known as falsework, to hold the formwork in place. The formwork should be carefully aligned and leveled to ensure an even and uniform concrete surface.

Concrete Placement: Once the formwork is in place, the concrete is poured into the designated area. The concrete mix should meet the specified strength and durability requirements. During the pouring process, special attention should be given to achieving proper consolidation and eliminating any voids or air pockets within the concrete.

Curing and Finishing: After the concrete is placed, it undergoes a curing process to allow it to gain strength and durability. Curing may involve the application of water or curing compounds to maintain moisture levels and promote proper hydration. Once the concrete has cured sufficiently, finishing processes such as leveling, troweling, and surface treatments are applied to achieve the desired appearance and texture.

Structural Connections: Finally, the structural connections between the composite floor system and other building elements, such as columns, walls, and stairs, are established. These connections ensure the overall stability and integrity of the structure.

Maintenance and Longevity of Composite Steel and Concrete Floors

Maintaining the integrity and longevity of composite steel and concrete floors is crucial to ensure the continued performance and safety of the structure. Here are some key considerations for maintenance:

Regular Inspections: Regular inspections of the composite floor system should be conducted to identify any signs of damage, wear, or deterioration. This includes examining the steel beams or joists for corrosion, checking the condition of the concrete slab for cracks or spalling, and assessing the integrity of the shear connectors. Inspections should be carried out by qualified professionals who are familiar with composite floor systems.

Cleaning and Maintenance: Routine cleaning of the composite floor system helps to remove dirt, debris, and potential contaminants that can affect its performance. Depending on the specific requirements and finishes of the floor, appropriate cleaning methods should be employed. This may include sweeping, mopping, or using specialized cleaning agents. Additionally, proper maintenance of the floor finishes, such as applying protective coatings or sealants, can help enhance durability and aesthetics.

Addressing Damage and Repairs: If any damage or deterioration is identified during inspections, prompt action should be taken to address and repair the issues. This may involve repairing or replacing damaged concrete sections, addressing corrosion on steel components, or reinforcing weakened areas. It is important to consult with structural engineers or professionals experienced in composite floor systems to ensure proper repair techniques are employed.

Fire Protection Measures: Maintaining the fire resistance of the composite floor system is essential for occupant safety. Regularly inspect and maintain fireproofing materials applied to the steel beams or joists. If any areas show signs of damage or degradation, they should be repaired or replaced to ensure the continued fire resistance of the floor system.

Load Management: Proper load management is crucial to prevent overloading and excessive stress on the composite floor system. Ensure that the floor is not subjected to loads beyond its design capacity. This includes monitoring and controlling the placement and distribution of heavy equipment, machinery, or storage on the floor. If modifications or changes to the building’s use occur, consult with a structural engineer to assess the impact on the floor system.

Preventive Measures: Implementing preventive measures can help prolong the lifespan of composite steel and concrete floors. This may include applying protective coatings to steel components to prevent corrosion, conducting regular maintenance on HVAC systems to control moisture levels, and implementing proper floor protection during construction or renovation activities.

STEEL CONCRETE COMPOSITE BEAMS – The Constructor

Steel-concrete composite frame Download Scientific Diagram

Specifying and achieving a level composite steel floor

Concrete Composite Floors u2013 Construction Details u2013 Structural Detailer

Composite beam Article about composite beam by The Free Dictionary

Design of composite slabs with profiled steel decking: a

Figure 2 from Advanced Design of Composite Steel-Concrete

Design of Composite Slab with Profile Metal Deck – Structville

Types of Floor Systems for Steel Framed Buildings – Structville

Related Posts: