In certain cases, almost all that will be needed is actually an easy rebuffing of the floors with a bit of polishing compound. Remember it's crucial to take concrete floor sealers to help look after the surface. It is accurate that one requires quite some simple approach of trying to look soon after these concrete floors but certain facts about maintenance that need to be kept under consideration.

Images about Concrete Floor Construction For Underfloor Heating

Concrete Floor Construction For Underfloor Heating

Once the concrete floor is clean and ready for the coating of its, it all comes down to timing. The floor at the hospital or perhaps food store may look glossy, attractive and very unique; this is just because it is a polished concrete floor. Polished concrete flooring offers a great visual sight while keeping a sensation of uniqueness & style about it.

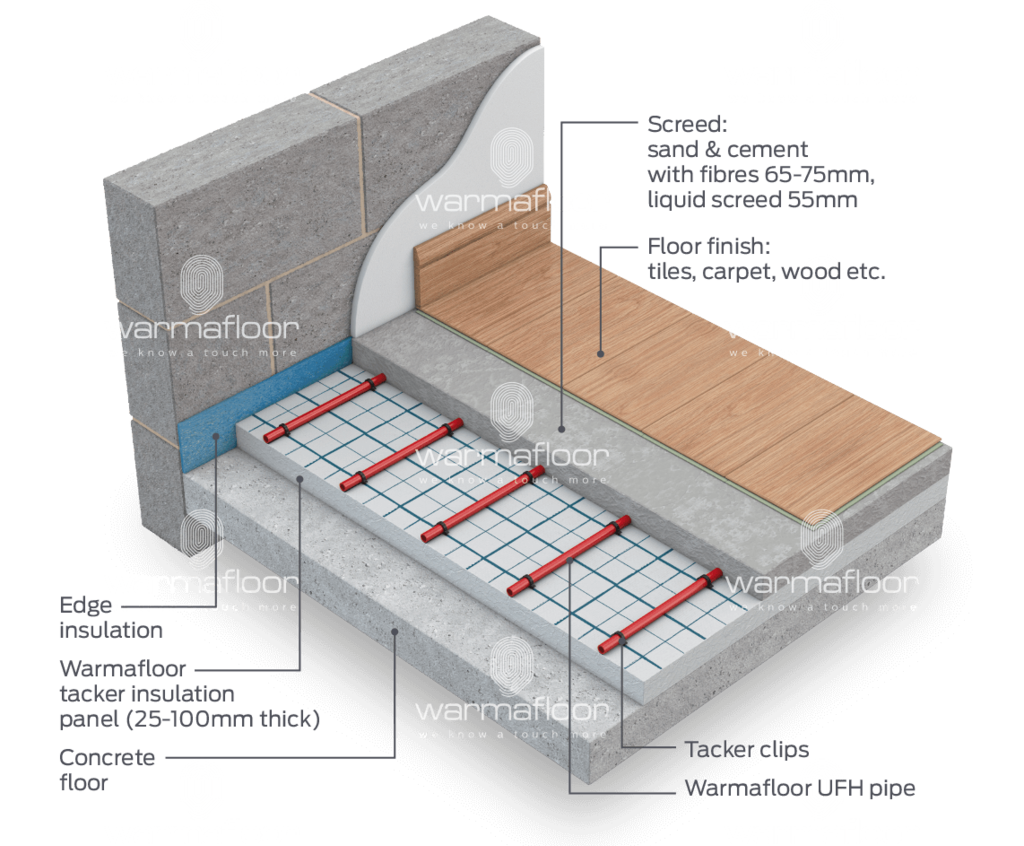

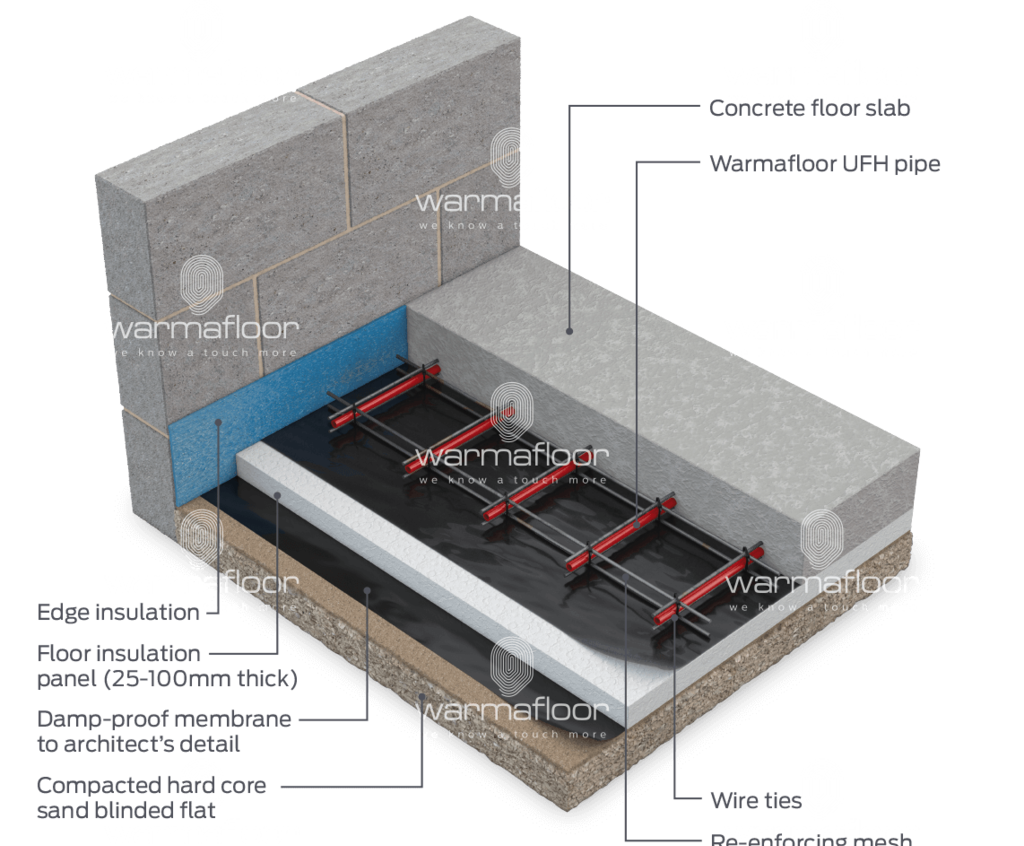

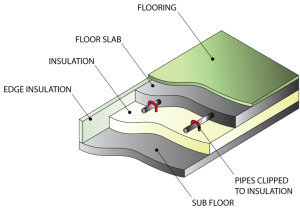

diagram of structural concrete slab floor with underfloor heating

Concrete flooring is increasing in acceptance and not just with industrial and commercial buildings, polished concrete floors is actually a leading choice in many homes across the nation. Concrete flooring is actually safe, healthy plus more comfy for youngsters, the parents of yours and for the entire family of yours. Cleaning couldn't be any easier when you've chosen to add in concrete polishing floors to your property.

Underfloor heating Ditch the radiators. – SDA Build London

Floor Construction – Underfloor Heating Systems Ltd

Floor Construction Underfloor Heating Air To Water – Diagram PNG

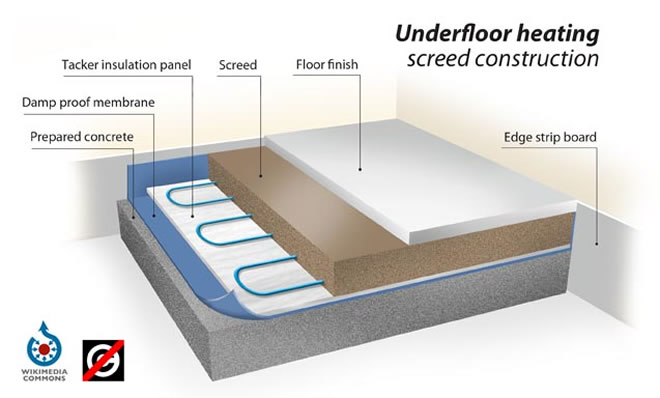

Underfloor Heating Floor Construction Types and Installation Methods.

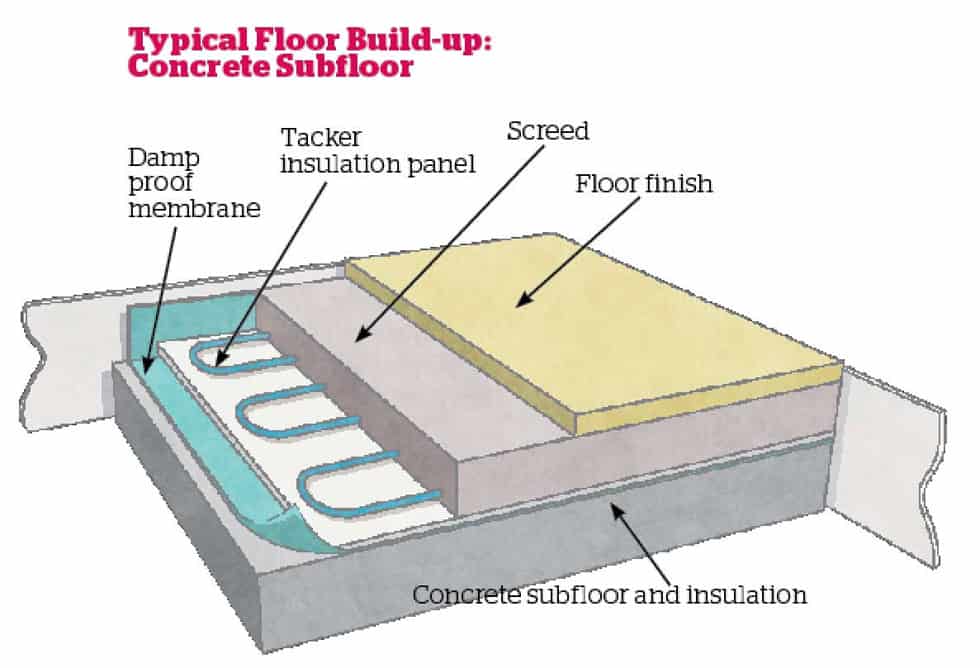

Tacker underfloor heating for screed / concrete floors

Underfloor Heating System Floor Constructions and Height/Build-Up

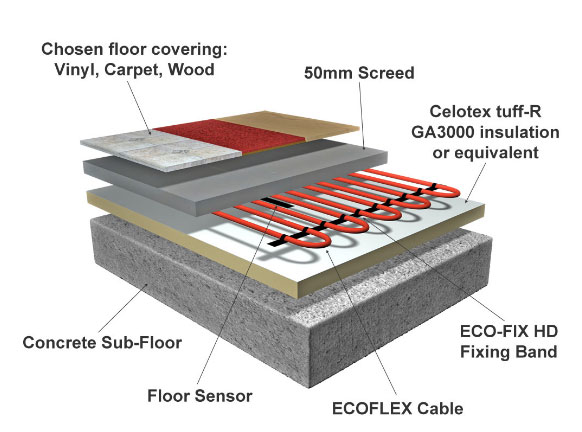

Inscreed Underfloor Heating Cable: Floor Construction

Borders Underfloor Heating supply and install underfloor heating

Efficient planning to avoid common underfloor heating mistakes

Underfloor Heating And Floor Height ThermoSphere

Water Underfloor Heating Floor Constructions

Installation of rigid floor insulation on ground floor concrete

Related Posts:

- Acid Wash Concrete Floor Colors

- Concrete Floor Thickness For A Garage

- Concrete Floor For Bathroom

- Interior Concrete Floor Ideas

- Kitchen Stained Concrete Floors

- Concrete Floor Tile Thickness

- How To Stain Concrete Floors DIY

- DIY Concrete Floor Grinding

- Concrete Floor Damage

- Faux Stained Concrete Floors

Introduction

Concrete floor construction for underfloor heating is a popular choice for residential and commercial buildings. It is a cost-effective solution that provides efficient heating and energy savings. This type of construction is also relatively easy to install and maintain. There are several benefits to using concrete floor construction for underfloor heating, such as improved insulation, better air quality, and greater comfort levels. In this article, we will discuss the basics of concrete floor construction for underfloor heating, its advantages, the different types of systems available, and FAQs about the process.

Benefits of Concrete Floor Construction for Underfloor Heating

Concrete floor construction for underfloor heating is a great choice for many reasons. One of the major benefits is that it provides excellent insulation against cold weather. The concrete helps to keep the heat from escaping and also helps to retain the heat within the building. This allows you to save money on energy costs since you won’t have to use as much energy to heat your home or business.

Another benefit of using concrete floor construction for underfloor heating is that it helps to improve air quality. Since it traps in the heat, it also helps to trap in pollutants, dust, and other airborne particles. This keeps them from entering your living space and improves your air quality. It also helps to reduce allergens in the air, which can be beneficial for people with allergies or asthma.

Finally, concrete floor construction for underfloor heating helps to create a more comfortable environment in your home or business. The warmth from the heated floors helps to make any room feel cozy and inviting. This can be especially helpful in colder climates where temperatures can dip below freezing during the winter months.

Types of Systems Available

When it comes to concrete floor construction for underfloor heating, there are several different types of systems available. These include electric systems, hydronic systems, and gas-fired systems. Each type of system has its own benefits and drawbacks, so it’s important to research each one carefully before making a decision.

Electric systems are the most common type of system used for underfloor heating. They are relatively easy to install and maintain, and they provide efficient heating at a low cost. However, they can be expensive to run since they require a significant amount of electricity.

Hydronic systems use hot water instead of electricity to heat your floors. These systems are more expensive than electric ones but can provide more consistent temperatures since they don’t require as much energy to operate. However, they do require regular maintenance since they rely on circulating hot water through pipes and radiators.

Gas-fired systems are another option for underfloor heating. These systems use natural gas or propane to heat your floors and can provide more consistent temperatures than electric systems. However, they can be more expensive to operate due to their reliance on gas or propane fuel sources.

Frequently Asked Questions

Q: How long does it take to install concrete floor construction for underfloor heating?

A: The installation process for concrete floor construction for underfloor heating generally takes between two and four days depending on the size of the project and the complexity of the system being installed. It is important to consult with a professional installer before beginning any project so that you can ensure that everything is done correctly and safely.

Q: What are some of the common problems associated with concrete floor construction for underfloor heating?

A: Some of the most common problems associated with concrete floor construction for underfloor heating include cracks in the concrete due to settlement or shifting soil beneath the slab, improper insulation leading to inefficient energy consumption, inadequate drainage leading to standing water beneath the slab, excessive moisture causing corrosion of piping or wiring beneath the slab, and insufficient ventilation leading to musty odors in your home or business space. It is important to consult with a professional installer before beginning any project so that you can ensure that all potential problems are identified and addressed prior to installation.

Q: What type of maintenance is required for concrete floor construction for underfloor heating?

A: The maintenance requirements for concrete floor construction for underfloor heating depends on the type of system being used. Generally speaking, electric systems require minimal maintenance while hydronic systems