Wooden floors require varnishing on a regular basis, carpets can be a nightmare which have to be cleaned frequently, while the concrete flooring surfaces are lasting and don’t need some maintenance, apart from a cleaning if needed. Today cleaning on a polished concrete floor is a lot easier and demands much less time. Concrete floors might be polished dry or wet.

Images about Concrete Floor Expansion Joint Covers

Concrete Floor Expansion Joint Covers

A spot remover exclusively formulated for concrete floor, like those sold at professional janitorial supply companies, can assist you. On the other hand, a polished concrete floor, and that is highly resistant to scuffs and stains, could be just mopped when necessary. The completed outcome is a very even surface, joints are slightly noticeable.

Floor Expansion Joint Covers – Thermal u0026 Seismic Joints Inpro

Even though you may be ready to keep your floor war with radiant floor heating fitted, if you do not have the choice and concrete flooring can be a bit of cold. Polished concrete floors, long consigned to done basements and industrial spaces, are actually creating well-deserved inroads into residential houses.

Floor Expansion Joint Cover · QuickCover · Sika Emseal

Expansion Joint Cover Plates Construction Specialties

Floor Expansion Joint Covers – Thermal u0026 Seismic Joints Inpro

Floor Expansion Joint Cover · QuickCover · Sika Emseal

Expansion Joint Cover Plates Construction Specialties

Floor Expansion Joint Covers – Thermal u0026 Seismic Joints Inpro

Expansion Joint Cover Plates Construction Specialties

Serrated Stainless Steel Floor Expansion Joint Cover Plate FM

Seismic Expansion Joint · SJS System · Sika Emseal

Aluminum Floor Expansion Joint Covers for Concrete – China

Related Posts:

- Polished Concrete Floors For Patios

- White Concrete Floor Tiles

- Acid Wash Concrete Floor Colors

- Concrete Floor Thickness For A Garage

- Concrete Floor For Bathroom

- Interior Concrete Floor Ideas

- Kitchen Stained Concrete Floors

- Concrete Floor Tile Thickness

- How To Stain Concrete Floors DIY

- DIY Concrete Floor Grinding

Introduction to Concrete Floor Expansion Joint Covers

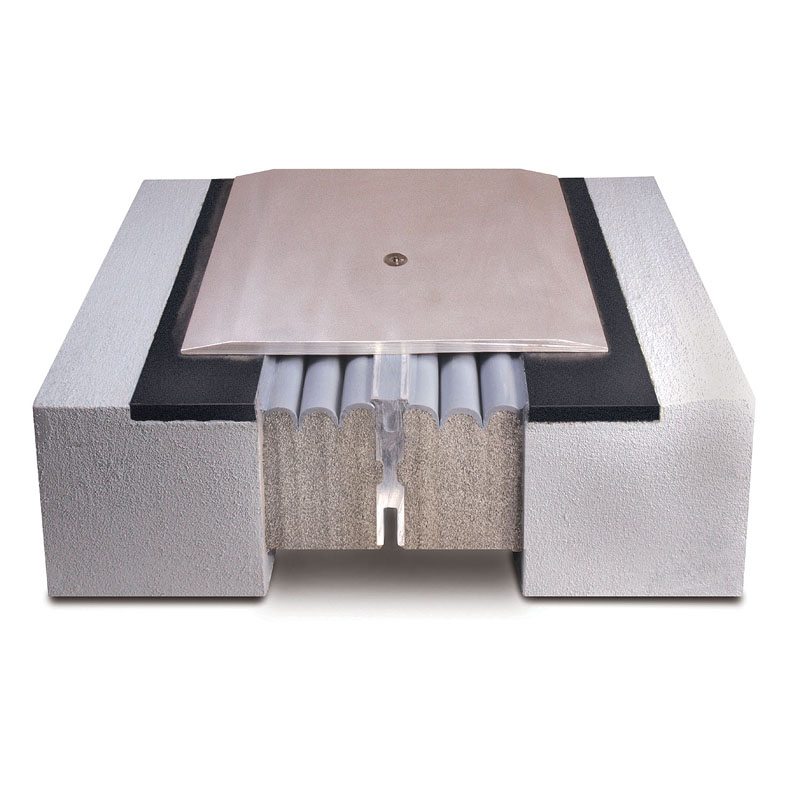

Concrete floor expansion joint covers are designed to protect the structural integrity of a concrete floor and create a barrier between two different materials used in the flooring system. Expansion joint covers, also known as control joints, provide an economical solution for controlling movement and preventing the cracking of the concrete floor. They are often used in residential, commercial, and industrial applications due to their durability and ease of installation. Expansion joint covers are highly economical compared to other techniques used to secure two concrete slabs together such as epoxy mortar or resin.

Understanding Expansion Joint Covers

Expansion joint covers are commonly made from rubber or plastic and are designed to absorb the pressure and movement caused by the expansion and contraction of two different concrete slabs. They are typically placed in areas where there is a change in material or a potential for stress on the concrete slab. The covers have an integral channel that is designed to prevent water and debris from entering the joint while allowing for movement between the two slabs. Expansion joint covers can also be made from metal or fiberglass depending on the application and are designed to provide protection against potential hazards such as abrasion, fire, and vibration.

Advantages of Using Expansion Joint Covers

Expansion joint covers provide many advantages when used in both residential and commercial applications. Firstly, they protect both slabs from damage caused by movement and vibration. This ensures that the integrity of each slab is preserved over time. Secondly, the cover acts as a barrier between two materials which prevents moisture from entering the joint area which can cause structural damage. Lastly, expansion joint covers are very cost effective compared to other methods used for securing two concrete slabs together which makes them highly attractive to builders and contractors.

Installation of Expansion Joint Covers

The installation process for expansion joint covers is relatively simple and can be completed without any specialist tools or knowledge. Firstly, all debris must be removed from the area where the cover will be placed to ensure that it will fit correctly. Once this has been done, the cover must be placed over the area and secured with nails or screws which helps to keep it in place. Finally, any excess sealant needs to be applied around the edges of the cover before it is left to set and harden over time.

FAQs About Concrete Floor Expansion Joint Covers

Q1. What are expansion joint covers used for?

A1. Expansion joint covers are used to protect the structural integrity of a concrete floor and create a barrier between two different materials used in the flooring system. They also absorb pressure and movement caused by expansion and contraction of two different concrete slabs.

Q2. Are expansion joint covers easy to install?

A2. Yes, installation of expansion joint covers is relatively simple and can be completed without any specialist tools or knowledge. All debris must be removed from the area before installation then they must be secured with nails or screws and any excess sealant needs to be applied around edges before it sets and hardens over time.

Q3. What are some advantages of using expansion joint covers?

A3. Some advantages of using expansion joint covers include protecting both slabs from damage caused by movement and vibration, acting as a barrier between two different materials to prevent moisture entering, and they are much more economical compared to other methods used for securing two concrete slabs together.

What material is used for concrete floor expansion joint covers?

Expansion joint covers for concrete flooring are typically constructed out of plastic, aluminum, or stainless steel. They are designed to absorb the pressure and movement caused by the expansion and contraction of two different concrete slabs and have an integral channel that is designed to prevent water and debris from entering the joint while still allowing for movement between the two slabs.

What are the different types of concrete floor expansion joint covers?

1. Control Joint Covers: This type of joint cover is designed to allow the natural expansion and contraction of the concrete floor while also providing a protective barrier. They are most commonly used in large and long areas such as highways, parking lots, warehouses, etc.

2. Expansion Joint Covers: This type of joint cover is designed to fill the gap between two sections of concrete allowing for movement due to temperature changes or to accommodate expansion. They are usually made from a plastic material such as polyethylene or polypropylene and can be easily cut to fit the outline of the joint.

3. Seamless Joint Covers: These types of joint covers are designed to provide a complete seal between the two concrete surfaces for a smooth and continuous transition. They are generally made of rubber and come in various thicknesses depending on the application, such as in wet areas or for more heavy duty applications like airports and ports.

4. Foam Expansion Joint Covers: These covers are designed to fill the gap created between two concrete surfaces due to expansion or contraction in different weather conditions. They are usually made of an open cell foam material that allows for flexibility while still maintaining a waterproof seal.

What is the purpose of concrete floor expansion joint covers?

Concrete floor expansion joint covers are used to protect expansion joints from water, debris, and other hazards. Expansion joints are essential in concrete floors and provide space for the concrete to move without causing cracks or damage. The use of these covers helps to ensure the joint remains in good condition and extends its lifespan.

What types of materials are used to make concrete floor expansion joint covers?

Concrete floor expansion joint covers are typically made of pre-formed, durable materials such as elastomeric sealants, rigid PVC or polyurethanes. The material must be able to stretch and compress with the expanding and contracting of the joints. Additionally, the material must be able to keep out water, debris, and other contaminants.

What is the purpose of concrete floor expansion joint covers?

Concrete floor expansion joint covers are used to fill the gap between two sections of concrete and prevent water, dirt, and debris from entering the joint. They also help bridge concrete movement caused by shifting temperatures to prevent cracking and spalling.