Nonetheless, visual appeal and the performance of concrete may be hampered by the useful protection aspects of its, particularly for children which are younger. When used in basements, possessing bare concrete floors is an even more hygienic option from moldy carpets & rugs.

Images about Concrete Floor Sanding Pads

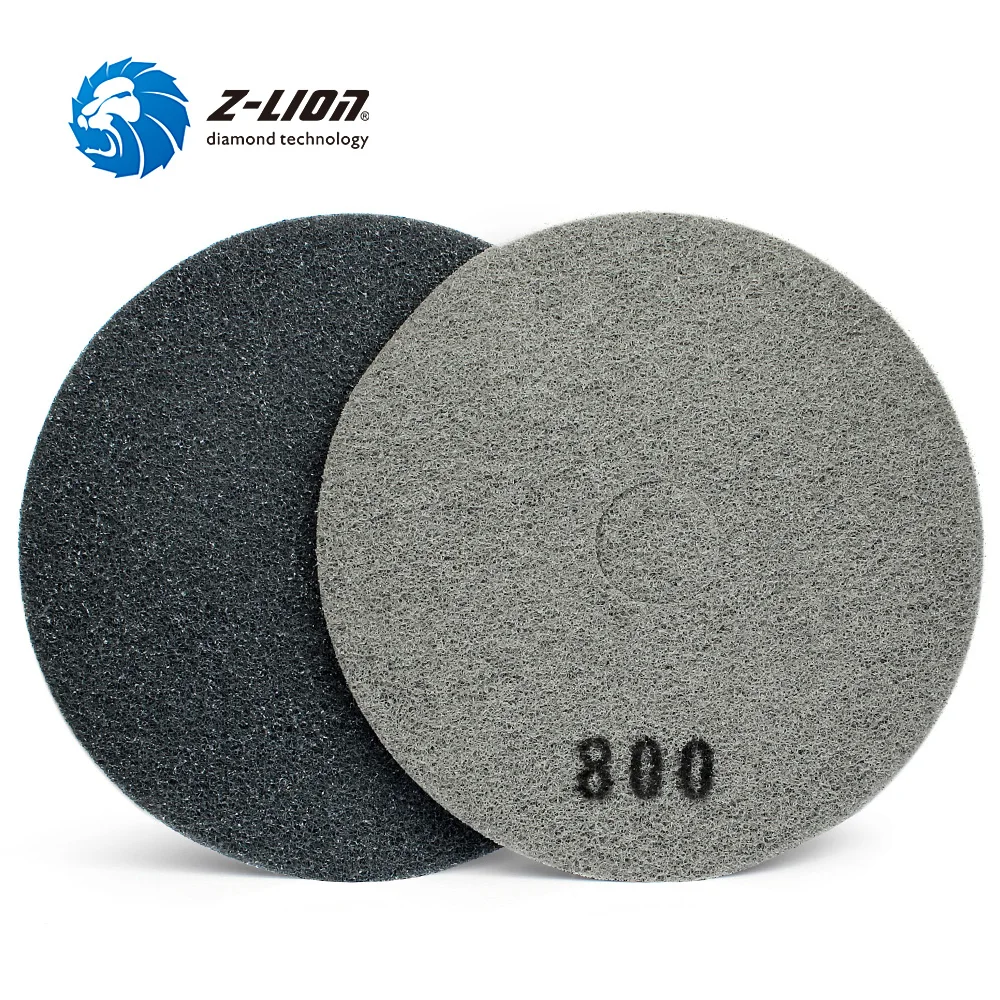

Concrete Floor Sanding Pads

Polished concrete flooring is one of the cheapest options as in comparison to other information used for flooring nowadays. It does work with the lime articles in the floor it's quite unpredictable but usually comes out looking rather good. It is additionally a good idea to survey the concrete floors frequently and remove some extra substances, like gum or stickers, and check out it for harm.

Concrete Diamond Sanding Pads Electroplated – YouTube

At the conclusion of this day, the polished concrete floor is going to look something like some sort of polished stone, no surprise it is applied as a decorative means in so many locations. If the concrete floor has been in the past sealed, it's a wise decision to sweep and next mop the area with water and soap, a general cleaning product or perhaps a qualified concrete cleaner.

8 Pcs 4″ Diamond Polishing Pads Concrete Grinding Disc Floor Sanding Resin Flexible Pad with Rubber Backer Diamond Tool

3 in. 3000-Grit Concrete Diamond Floor Polishing Pads/Discs

Concrete DNA™ Diamond Satellite Pads

Floor Buffing Pads for Concrete and Natural Stone – 17 Inch Buffer

Z-LION 3″ Diamond Concrete Grinding Pad 10 Segments Metal Bond Floor Sanding Polishing Disc Grit 60 120 Diamond Grinding Wheel

3 in. 100-Grit Concrete Diamond Floor Polishing Pads/Discs

DIAMOND PAD Concrete Polishing by Ultra Chem Labs

SPTA 15pcs Diamond Wet Polishing Pads Set, 4 inch Pads for Granite

Stadea Diamond Floor Polishing Pads For Concrete Granite Marble – Series Std J

Z-LION 17″ 4pcs Fiber Sponge Polishing Pad Concrete Floor Cleaning u0026 Polishing Wheel Diamond Buffing Disc 400/800/1500/3000 Grit

Concrete Sanding and Polishing in 6 Easy Steps – ConcreteSanders

How To Diamond Grind A Concrete Floor

Related Posts:

- White Concrete Floor Tiles

- Acid Wash Concrete Floor Colors

- Concrete Floor Thickness For A Garage

- Concrete Floor For Bathroom

- Interior Concrete Floor Ideas

- Kitchen Stained Concrete Floors

- Concrete Floor Tile Thickness

- How To Stain Concrete Floors DIY

- DIY Concrete Floor Grinding

- Concrete Floor Damage

Introduction

Concrete floor sanding pads are a necessary tool for any concrete project. They provide the necessary abrasion and polishing to the concrete, creating a smooth and even surface. They come in a variety of shapes and sizes, allowing for easy application of the abrasive surface. These pads are used in a variety of applications, from polishing concrete floors to removing grout or paint. With their versatile range of uses, concrete floor sanding pads are an invaluable tool for any concrete job.

Types of Concrete Floor Sanding Pads

There are several different types of concrete floor sanding pads available on the market. The most common type is the diamond-impregnated pad, which is designed to provide maximum abrasive action on concrete floors with minimal effort. These pads are usually made from a combination of diamond grit and other abrasive materials, such as aluminum oxide or silicon carbide. The diamond grit provides a powerful and effective cutting action, while the other abrasive materials provide a smoother finish. Diamond-impregnated pads can be used on both dry and wet surfaces, making them ideal for both residential and commercial applications.

Another type of concrete floor sanding pad is the diamond-coated pad. These pads are designed to provide a smoother finish than the diamond-impregnated pads, yet still offer an effective level of abrasive action. Diamond-coated pads are most often used on dry surfaces and can be used in both residential and commercial applications.

A third type of concrete floor sanding pad is the silicon carbide pad. These pads are made from a combination of silicon carbide and other abrasive materials, such as aluminum oxide or diamond grit. Silicon carbide pads are designed to provide a very smooth finish, yet still offer an effective level of abrasive action. They can be used on both dry and wet surfaces and can be used in both residential and commercial applications.

Finally, there are also foam-backed sanding pads available on the market. These sanding pads are designed to provide a softer finish than the other types of sanding pads. Foam-backed sanding pads are often used in residential applications where a softer finish is desired. They can be used on both dry and wet surfaces and can be used in both residential and commercial applications.

Benefits of Concrete Floor Sanding Pads

Concrete floor sanding pads offer many benefits for both homeowners and contractors alike. One of the main advantages is that they provide an effective level of abrasive action without having to use a power tool or machine. This helps to reduce fatigue when working on large projects or when working in tight spaces. Furthermore, concrete floor sanding pads provide a smooth finish that will last for years without needing to be replaced or repaired. This helps to ensure that your project will look great for years to come without having to worry about damage or wear over time. Additionally, the various types of sanding pads available allow you to select the perfect tool for each job, ensuring that you get the best results possible every time.

FAQs About Concrete Floor Sanding Pads

Q: What are concrete floor sanding pads?

A: Concrete floor sanding pads are tools designed to provide an effective level of abrasion and polishing to concrete surfaces, creating a smooth and even finish. They come in several different types, including diamond-impregnated, diamond-coated, silicon carbide, and foam-backed forms, allowing for easy application of the abrasive surface depending on the job at hand.

Q: What are the benefits of using concrete floor sanding pads?

A: The main benefit of using these tools is that they provide an effective level of abrasion and polishing without having to use a power tool or machine, which helps reduce fatigue when working on large projects or when working in tight spaces. Additionally, they provide a smooth finish that will last for years without needing to be replaced or repaired, helping to ensure that your project looks great for years to come without worrying about damage or wear over time. Finally, their versatile range allows you to select the perfect tool for each job, ensuring that you get the best results possible every time.