This choice revolves around the facts that epoxy flooring is highly durable, requires minimum maintenance and is environmentally friendly. This would lessen any wastage and help save you cash. The professionals know each and every element of the surfacing and they can easily use the most recent technology for using the epoxy paint over your floors.

Images about Esd Epoxy Floor Paint

Esd Epoxy Floor Paint

Manufacturing epoxy floors coating products are excellent materials for floor beautification. It is incredibly cost-effective as well as because it is long-lasting, epoxy flooring is a lasting expense. Especially those businesses with heavy machinery and forklifts used at the plant as well as factory. Additionally, epoxy flooring produces concrete visually appealing and very simple to clean.

ESD Epoxy Floor Paint

Epoxy coatings are going to react with previously installed coatings. By just adding a work bench as well as some epoxy flooring covering you've a professional looking task and a floor that may be enjoyed for many years to come. You will be wondering off including a shop or even transforming your garage right into a work shop. The best thing about epoxy is it creates an appealing yet very simple appearance.

Static Control Floor Paint / ESD Epoxy Floor Paints

ESD Epoxy Floors, ESD Epoxy Flooring, Epoxy Floor Coating

ElectraGuard® ESD Epoxy Flooring: u003c$2.00PSF

Static Control (ESD) Epoxy Floor Coating Systems

Introducing our New, vebrostatic ESD Seamless Epoxy Flooring Range

HB-97.2 ESD Conductive Epoxy Primer ANSI S20.20-2014 In 7 colors

Anti-Static Epoxy Flooring – Methods and Applications – The

Anti Static Epoxy Flooring ESD Epoxy Flooring Jemkon

Static Control Epoxy Flooring u0026 CRU Coatings Industrial Concrete

4700SS ESD Static Dissipative Acrylic Polyurethane Anti-Static Floor Paint ANSI/ESD S20.20-2014

Maydos 2k Self Leveling Static Conductive ESD Epoxy Resin Floor Paint

ESD floor coatings for electrostatic discharge protection

Related Posts:

- White Epoxy Garage Floor

- Epoxy Gloss Floor Paint

- Epoxy Concrete Floor Covering

- Thick Epoxy Floor Coating

- Epoxy Paint Floor Finish

- Epoxy Floor Coating For Basement

- White Metallic Epoxy Floor

- Metallic Epoxy Floor Installation

- Red Epoxy Floor

- Clear Epoxy Shower Floor

Introduction To Esd Epoxy Floor Paint

Esd epoxy floor paint is an incredibly versatile and durable floor coating system designed to provide superior protection against electrostatic discharge (ESD) in environments where sensitive electronic equipment is used. This type of floor coating is perfect for manufacturing, cleanroom, and laboratory settings. It provides a strong, slip-resistant surface that stands up to heavy traffic and harsh chemicals. It is also highly resistant to bacteria, mold, and other contaminants. This article will explore the many benefits of esd epoxy floor paint, its application process, and the proper care and maintenance procedures needed to prolong its lifespan.

What Is Esd Epoxy Floor Paint?

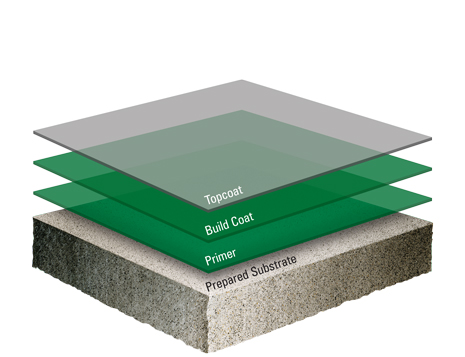

Esd epoxy floor paint is a specialized epoxy-based coating that is specifically designed for use in electrostatic discharge (ESD) sensitive environments. It is composed of two parts: a base component made from a combination of epoxy resins and fillers, and a topcoat component made from a combination of specialized epoxies and additives. When applied to a concrete floor, this type of coating provides an extremely durable, slip-resistant surface that protects against ESD, bacteria, mold, and other contaminants. It also provides superior resistance to wear and tear, making it ideal for high-traffic areas.

Benefits Of Esd Epoxy Floor Paint

There are many advantages of esd epoxy floor paint. In addition to its superior protection against ESD, it also offers superior resistance to wear and tear, making it ideal for high-traffic areas. It also provides excellent protection against bacteria, mold, and other contaminants. Additionally, esd epoxy floor paint is highly resistant to stains and other surface damage caused by chemicals or abrasive materials. Finally, it is an extremely cost-effective solution for maintaining the integrity of sensitive electronic equipment in commercial and industrial settings.

Application Process Of Esd Epoxy Floor Paint

The application process of esd epoxy floor paint can be broken down into three steps: preparation of the surface, application of the coating, and curing of the coating. First, the surface must be properly prepared by removing all dirt, grease, waxes, oils, curing agents or sealers that may be present on the concrete floor. Next, the epoxy coating must be mixed according to manufacturer’s instructions and applied with a brush or roller in thin coats until the desired finish is achieved. Lastly, the coating must be given sufficient time to cure before it can be put into service.

Care And Maintenance Of Esd Epoxy Floor Paint

To ensure that your esd epoxy floor paint remains in top condition for years to come, it is important to follow proper care and maintenance procedures. The most important step is regular cleaning using a mild detergent or neutral cleaner specifically designed for use on epoxy floors. Additionally, it is important to avoid using harsh chemicals or abrasive materials that could damage the coating. Finally, it is essential to inspect the floor regularly for signs of wear or damage so that any areas in need of repair can be addressed quickly.

FAQs About Esd Epoxy Floor Paint

Q: How long does esd epoxy floor paint last?

A: With proper care and maintenance, esd epoxy floor paint can last up to 10 years before needing to be replaced.

Q: What type of surface can esd epoxy floor paint be applied on?

A: Esd epoxy floor paint can be applied on any type of concrete or masonry surface that has been properly prepared prior to application.

Q: Is esd epoxy floor paint slip resistant?

A: Yes, when applied correctly esd epoxy floor paint provides an extremely slip-resistant surface that stands up to heavy traffic and harsh chemicals.

Q: Does esd epoxy floor paint provide protection against bacteria?

A: Yes, esd epoxy floor paint provides excellent protection against bacteria as well as mold and other contaminants.

Conclusion

In conclusion, esd epoxy floor paint is a highly versatile and highly durable floor coating system designed specifically for use in electrostatic discharge (ESD) sensitive