The Importance of a Proper Subfloor for Successful Hardwood Floor Installation

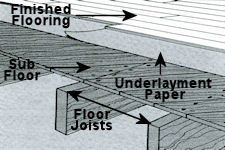

When embarking on the installation of hardwood floors, the significance of a well-prepared subfloor cannot be overstated. A proper subfloor serves as the foundation for a stable and enduring hardwood floor. Let’s explore the crucial role it plays through a concise list of reasons:

Prevention of Warping and Buckling:

- A suitable subfloor is paramount in averting the warping or buckling of hardwood floors.

- Hardwood is sensitive to moisture, and an inadequate subfloor can allow moisture to permeate, causing the floorboards to expand or contract.

- Solid subfloors act as a barrier, safeguarding the integrity of the hardwood flooring by preventing the infiltration of moisture.

Noise Reduction and Insulation:

- Properly installed and insulated subfloors contribute significantly to noise reduction associated with hardwood floors, especially in high-traffic areas.

- By minimizing sound transmission, a well-prepared subfloor enhances the living environment, fostering a quieter and more comfortable space.

- Additionally, it acts as insulation against cold drafts, helping maintain warmth during colder months.

Support System for Weight Distribution:

- The subfloor serves as a vital support system for hardwood flooring, evenly distributing weight and pressure across the entire floor.

- This even distribution is crucial, especially in areas with heavy furniture or significant foot traffic, preventing individual floorboards from overloading and potential damage.

Ensuring a Professional and Visually Appealing Result:

- A proper subfloor provides a smooth and level surface for hardwood flooring installation.

- Achieving a professional and visually appealing result hinges on the levelness of the subfloor.

- Without a level foundation, hardwood flooring may exhibit unevenness or noticeable dips and bumps, detracting from its overall aesthetic appeal.

Types of Subfloor Materials Suitable for Hardwood Floor Installation

There are various types of subfloor materials that are suitable for hardwood floor installation. These subfloor materials provide a stable and level surface for the hardwood flooring to be installed on. Here are some common types of subfloor materials:

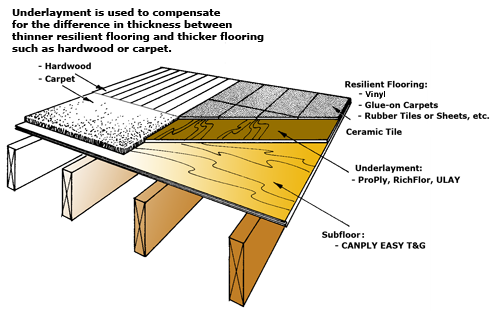

Plywood: Plywood is a popular choice for subflooring in hardwood floor installations. It is made up of multiple layers of thin wood veneers that are glued together. Plywood is known for its strength and durability, making it an excellent choice to support the weight of hardwood flooring.

Oriented Strand Board (OSB): OSB is another commonly used subfloor material for hardwood floor installations. It is made by compressing and bonding wood strands together with adhesive. OSB is known for its high structural strength and moisture resistance, making it suitable for areas with higher humidity levels.

Cement board: Cement board is a suitable subfloor material for hardwood floor installations in areas with high moisture, such as bathrooms and basements. It is typically made of cement reinforced with fiberglass mesh, providing a stable and moisture-resistant surface for hardwood flooring.

Gypsum concrete: Gypsum concrete is a lightweight and fire-resistant subfloor material that is commonly used in multi-story buildings. It is made by mixing gypsum powder with water and aggregate, creating a pourable material that can be easily leveled and smoothed.

Concrete: Concrete is a solid and durable subfloor material that is commonly used in basements and on ground-level floors. It provides a stable base for hardwood flooring and can be further enhanced with moisture barriers to prevent moisture-related issues.

Preparation and Inspection of Subfloor before Hardwood Floor Installation

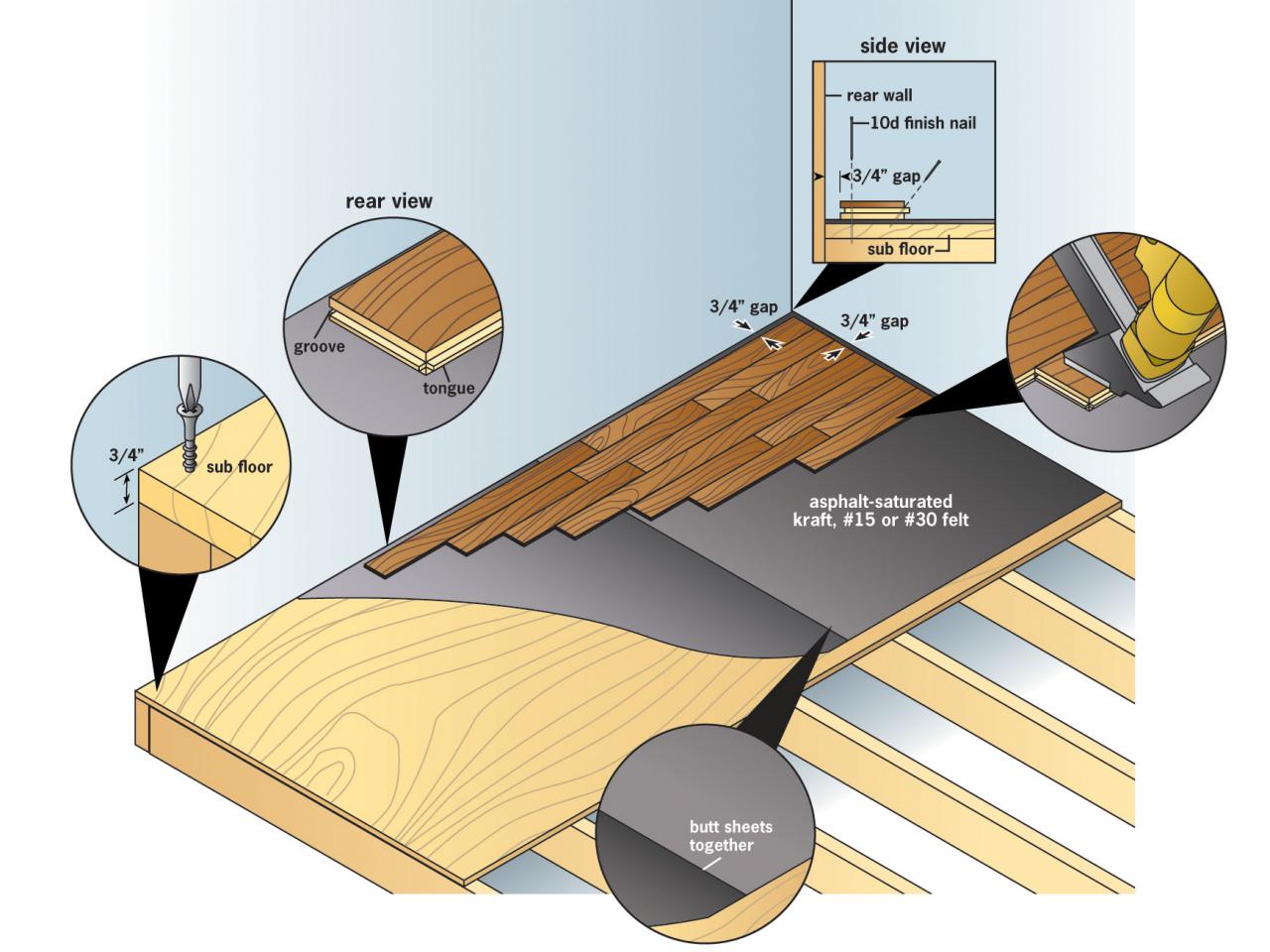

Before starting the installation of hardwood flooring, it is essential to properly prepare and inspect the subfloor. This ensures that the subfloor is in good condition and provides a stable foundation for the hardwood floor.

The first step in the preparation process is to remove any existing flooring materials, such as carpet, vinyl, or laminate. This allows for a clean and even surface to work with. It is important to carefully remove these materials to avoid damaging the subfloor.

Once the existing flooring is removed, the subfloor should be thoroughly inspected for any signs of damage or unevenness. Any loose or damaged areas should be repaired or replaced to ensure a solid base for the hardwood floor. This may involve fixing squeaky or loose floorboards, filling in gaps or cracks, or leveling uneven areas.

In addition to inspecting for damage, it is crucial to check the moisture levels of the subfloor. Moisture can cause hardwood flooring to warp or buckle over time. Using a moisture meter, the subfloor should be tested in various areas to ensure it meets the manufacturer’s recommended moisture content. If the moisture levels are too high, it may be necessary to address the underlying cause and allow the subfloor to dry before proceeding with the installation.

Furthermore, it is important to consider the type of subfloor material and its compatibility with hardwood flooring. Different subfloor materials, such as plywood or concrete, may require specific preparation techniques or additional layers, such as underlayment or moisture barriers, to ensure optimal performance of the hardwood floor.

Lastly, the subfloor should be thoroughly cleaned and free of any debris, dust, or adhesive residue. This provides a clean surface for the adhesive or nails used during the installation process.

Common Issues and Solutions

1. Uneven Subfloor Surface:

One common issue in subfloor preparation for hardwood floor installation is an uneven subfloor surface. This can be caused by various factors, such as settling or shifting of the foundation, improper installation of the subfloor, or natural imperfections in the subfloor material. An uneven subfloor can lead to problems with the installation and can result in an uneven or unstable hardwood floor.

Solution: The solution to an uneven subfloor surface is to level it before installing the hardwood floor. This can be done by using a self-leveling compound, which is a cementitious material that is poured onto the subfloor and spreads out to create a level surface. The self-leveling compound is then left to dry and cure before the hardwood floor installation.

2. Moisture and Humidity Issues:

Moisture and humidity can cause significant problems for hardwood floor installations. Excessive moisture in the subfloor can lead to wood expansion, warping, and buckling. High humidity levels can also contribute to these issues. It is crucial to address moisture and humidity concerns before installing hardwood floors to ensure the longevity and stability of the flooring.

Solution: To prevent moisture and humidity issues, it is essential to test the subfloor for moisture content before installation. Moisture meters can be used to determine if the subfloor has excessive moisture levels. If moisture is detected, proper measures should be taken to address the issue, such as installing a moisture barrier or using a dehumidifier. It is also important to ensure proper ventilation in the room to minimize humidity levels.

3. Subfloor Cleanliness:

Another common issue in subfloor preparation is the cleanliness of the subfloor. Dust, dirt, debris, and adhesive residue can hinder the adhesion of the hardwood floor to the subfloor, resulting in an unstable installation.

Solution: The subfloor should be thoroughly cleaned and free from any contaminants before hardwood floor installation. This can be done by sweeping, vacuuming, and wiping the subfloor to remove any dust, dirt, or debris. Adhesive residue can be removed using appropriate adhesive removers or solvents. A clean and smooth subfloor provides a suitable surface for the hardwood floor to adhere to.

All About Subfloors – installing flooring over various sub-floors

Your Sub-Floor and You: What Lies Beneath – Reno-Tahoe-Nevada

Proper subfloor for hardwood in a renovation – Home

9 Common Sub-Floor Installation Mistakesu2014and How to Avoid Them

How To Install Nail Down Flooring Sale, 55% OFF www

Better Floor Performance Starts With a Solid Subfloor System

Related Posts:

- Hardwood Flooring Rustic Look

- Using Hardwood Flooring For Stairs

- Hardwood Floor Stain Removal Tips

- Hardwood Floor Installation Cost Vancouver

- Vinyl Tile Hardwood Flooring

- Hardwood Flooring Black Walnut

- Images Of Maple Hardwood Floors

- Finishing Hardwood Floors By Hand

- American Hickory Hardwood Flooring

- Hardwood Floor Cleaner For Scratches