Building Garage Floor: Materials and Considerations

When it comes to constructing a garage floor, selecting the right materials is crucial for longevity and functionality. Various options are available, each with its unique benefits and considerations. Let’s discuss some of the most common materials used in building garage floors and the factors to consider before making your choice.

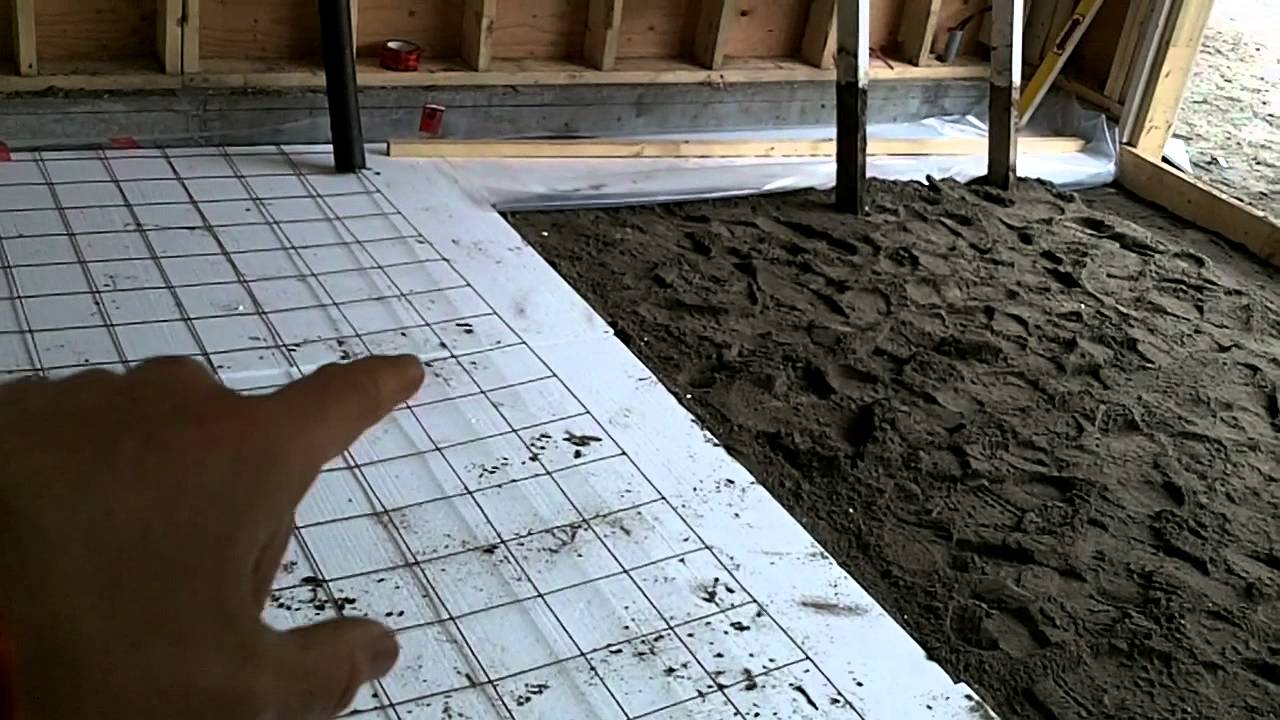

- Concrete: Concrete is the traditional choice for garage floors, prized for its durability and affordability. It can withstand heavy loads, resist stains, and provide a smooth surface for vehicles and activities. When opting for concrete, ensure proper curing and sealing to prevent cracking and moisture penetration. Additionally, consider adding reinforcement such as rebar or wire mesh for added strength, especially if your garage will bear heavy loads.

- Epoxy Coatings: Epoxy coatings offer a durable and visually appealing option for garage floors. Composed of epoxy resin and hardeners, these coatings create a chemical bond with the concrete, resulting in a tough, glossy surface that resists stains and abrasions. Epoxy coatings come in a variety of colors and finishes, allowing for customization to match your garage’s aesthetic. Keep in mind that proper surface preparation is essential for adhesion, and follow manufacturer instructions meticulously for best results.

- Interlocking Tiles: Interlocking tiles provide a convenient alternative to traditional garage floor materials. Made from materials like PVC or polypropylene, these tiles are durable and easy to install without adhesives or special tools. They can withstand heavy loads and vehicular traffic, making them suitable for garage environments. Interlocking tiles come in various styles and colors, allowing for customization and easy replacement of damaged tiles.

- Rubber Flooring: Rubber flooring is an excellent choice for homeowners seeking a comfortable and protective surface for their garage floors. Made from recycled rubber materials, it provides cushioning underfoot, reducing fatigue and impact on joints. Additionally, rubber flooring is resistant to oil, grease, and other chemicals commonly found in garages. Consider rubber flooring if you prioritize comfort and safety in your garage space.

- Considerations Before Building: Before selecting materials for your garage floor, consider factors such as climate, usage, and budget. In colder climates, for example, concrete floors may be prone to cracking due to freeze-thaw cycles, while epoxy coatings may provide better resistance. Additionally, assess how you plan to use your garage – if heavy vehicles or equipment will be present, opt for materials that can withstand the added weight and wear.

- Environmental Impact and Sustainability: Last, consider the environmental impact of your chosen materials. Opting for eco-friendly options such as recycled rubber flooring or low VOC (volatile organic compound) epoxy coatings can minimize your carbon footprint and contribute to a healthier indoor environment. Look for certifications such as LEED (Leadership in Energy and Environmental Design) to ensure that your garage floor materials meet sustainability standards.

Preparing the Surface

Before applying any coatings or finishes to your garage floor, thorough surface preparation is essential to ensure proper adhesion and longevity. Cleaning and repairing any damage are crucial steps in this process. Follow this step-by-step guide on how to prepare your garage floor effectively.

Clearing the Space

Start by removing all items from your garage floor, including vehicles, tools, and storage items. Clearing the space allows for a thorough inspection of the floor’s condition and ensures uninterrupted access during the preparation process. Sweep or vacuum the floor to remove loose debris and dirt.

Cleaning the Surface

Next, thoroughly clean the garage floor using a degreaser or concrete cleaner. Pay particular attention to areas with oil stains, grease buildup, or other contaminants that may affect adhesion. Use a stiff-bristled brush or pressure washer to scrub the surface and remove stubborn stains. Rinse the floor thoroughly with clean water and allow it to dry completely before proceeding.

Repairing Damage

Inspect the garage floor for any cracks, chips, or spalling and repair them using an appropriate patching compound or epoxy filler. Follow the manufacturer’s instructions for mixing and applying the repair material, ensuring that it fills the damaged areas and creates a smooth, level surface. Allow the repairs to cure fully before moving on to the next step.

Etching the Surface

Etching is a critical step in preparing a concrete garage floor for coatings or finishes. It opens up the pores of the concrete, allowing coatings to penetrate and adhere more effectively. Use a concrete etching solution or muriatic acid following the manufacturer’s instructions. Apply the etching solution evenly to the surface using a pump sprayer or mop, then scrub the floor with a stiff brush to ensure thorough coverage. Rinse the floor with clean water and allow it to dry completely before proceeding.

Final Inspection

Once the surface is cleaned, repaired, and etched, perform a final inspection to ensure it is ready for the next phase of construction. Check for any remaining debris, stains, or damage that may need to be addressed before proceeding. Taking the time to properly prepare the surface will ensure a successful outcome and prolong the life of your garage floor coatings and finishes.

Safety Precautions

Throughout the preparation process, prioritize safety by wearing appropriate personal protective equipment (PPE) such as gloves, goggles, and a respirator. Avoid direct skin contact with chemicals and ensure adequate ventilation in the workspace to prevent exposure to fumes. Additionally, follow all safety guidelines provided by manufacturers for the use of cleaning agents, repair materials, and etching solutions.

Choosing the Right Products: Sealants, Coatings, and Finishes

Selecting the appropriate sealants, coatings, and finishes is crucial for protecting and enhancing your garage floor. With a wide range of products available on the market, it’s essential to consider factors such as durability, aesthetics, and ease of application. Here’s a guide to help you choose the right products for your garage floor.

Sealants: Protecting Against Moisture and Stains

Sealants are essential for protecting concrete garage floors from moisture penetration and stains. They form a protective barrier that prevents water, oil, and other contaminants from seeping into the concrete, prolonging its lifespan and maintaining its appearance. Choose a penetrating sealant for optimal protection, as it penetrates deep into the concrete pores without altering its appearance or texture. Consider factors such as drying time, VOC content, and coverage rate when selecting a sealant for your garage floor.

Coatings: Adding Strength and Visual Appeal

Coatings provide an extra layer of protection and aesthetics to garage floors, enhancing durability and visual appeal. Epoxy coatings are a popular choice due to their durability, chemical resistance, and customizable finishes. Polyurethane coatings offer excellent UV resistance and abrasion resistance, making them suitable for outdoor applications. When choosing a coating, consider factors such as surface preparation requirements, curing time, and compatibility with existing sealants or coatings.

Finishes: Customizing the Look of Your Garage Floor

Finishes allow you to customize the appearance of your garage floor while providing additional protection against wear and tear. Choose from a variety of finishes such as glossy, satin, or matte, depending on your aesthetic preferences and functional requirements. High-gloss finishes offer a sleek, professional look and are easy to clean, making them ideal for high-traffic areas. Satin and matte finishes provide a more subdued appearance while still offering protection against stains and abrasions.

Considerations for DIY vs. Professional Installation

When selecting products for your garage floor, consider whether you’ll be applying them yourself or hiring a professional contractor. DIY kits are available for many sealants, coatings, and finishes, offering convenience and cost savings for homeowners. However, professional installation may be necessary for complex projects or if you lack experience with concrete coatings. Factor in your skill level, available time, and budget when deciding between DIY and professional installation.

Compatibility with Climate and Usage

Consider the climate and intended usage of your garage when choosing products for your floor. In areas with extreme temperature fluctuations, opt for products that can withstand freeze-thaw cycles and UV exposure. If your garage will be used for heavy-duty tasks such as automotive repair or woodworking, choose products with enhanced chemical and abrasion resistance. Consult with a knowledgeable supplier or contractor to ensure that your chosen products are suitable for your specific requirements.

Step-by-Step Guide to Applying Garage Floor Coatings

Applying garage floor coatings is a rewarding DIY project that can enhance the durability and appearance of your garage space. With proper preparation and technique, you can achieve professional-quality results that will protect your floor for years to come. Follow this step-by-step guide to learn how to apply garage floor coatings effectively.

Gather Your Materials

Before you begin, gather all the necessary materials and equipment for the job. This may include epoxy or polyurethane coating kits, mixing buckets, paint rollers or brushes, concrete etching solution, degreaser, protective gear (gloves, goggles, respirator), and a pressure washer or scrub brush for cleaning.

Prepare the Surface

Start by clearing the garage floor of any debris and cleaning it thoroughly with a degreaser or concrete cleaner. Use a pressure washer or scrub brush to remove stubborn stains and dirt. Allow the floor to dry completely before proceeding to the next step.

Etch the Surface

Etching is essential for promoting adhesion between the coating and the concrete surface. Mix the concrete etching solution according to the manufacturer’s instructions and apply it to the floor using a pump sprayer or mop. Scrub the floor thoroughly with a stiff brush to ensure even coverage. Rinse the floor with clean water and allow it to dry completely before proceeding.

Mix and Apply the Coating

Mix the epoxy or polyurethane coating according to the manufacturer’s instructions, ensuring thorough blending of the resin and hardener components. Pour the mixed coating onto the floor in small sections and spread it evenly using a paint roller or brush. Work quickly to ensure proper coverage and avoid drips or uneven application.

Apply Additional Coats (if necessary)

Depending on the type of coating and desired thickness, you may need to apply multiple coats for optimal protection and appearance. Allow each coat to dry according to the manufacturer’s instructions before applying the next one. Use a roller or brush to ensure even coverage and smooth out any imperfections.

Allow for Proper Curing Time

After applying the final coat, allow the coating to cure fully before subjecting it to foot traffic or heavy loads. Curing times can vary depending on the product and environmental conditions, so refer to the manufacturer’s instructions for guidance. Avoid parking vehicles or placing heavy objects on the floor until the coating has fully cured to prevent damage.

Enjoy Your Newly Coated Garage Floor

Once the coating has cured, enjoy the benefits of your newly coated garage floor. The durable, high-gloss finish will provide long-lasting protection against stains, abrasions, and moisture, enhancing the overall appearance and functionality of your garage space.

Maintenance Tips for Long-lasting Garage Floors

Maintaining your garage floor is essential for preserving its appearance and durability over time. By following these maintenance tips, you can ensure that your garage floor remains in top condition for years to come.

Regular Cleaning

Keep your garage floor clean by sweeping or vacuuming regularly to remove dirt, dust, and debris. For stubborn stains or spills, use a mild detergent or concrete cleaner and a scrub brush to spot clean as needed. Avoid using harsh chemicals or abrasive cleaners, as they can damage the surface of the floor.

Protective Measures

Place mats or rugs in high-traffic areas to protect the floor from wear and tear. Use furniture pads or casters on heavy items such as workbenches or tool chests to prevent scratching or indentation of the floor. Avoid dragging heavy objects across the floor, as this can cause damage to the coating or finish.

Prompt Repairs

Inspect your garage floor regularly for signs of damage such as cracks, chips, or peeling coatings. Promptly repair any damage using appropriate patching materials or epoxy fillers to prevent further deterioration. Addressing minor issues early can help prevent more significant problems down the line.

Avoiding Chemical Exposure

Be cautious when storing or using chemicals such as gasoline, oil, or solvents in your garage. Spills or leaks can damage the coating or finish of your floor, leading to stains or discoloration. Store chemicals in sealed containers and clean up spills immediately to minimize potential damage.

Periodic Maintenance

Periodically inspect your garage floor for signs of wear and tear, especially in high-traffic areas or where vehicles are parked. Depending on the type of coating or finish used, you may need to reapply a sealer or topcoat every few years to maintain protection and appearance. Follow the manufacturer’s recommendations for reapplication frequency and procedures.

Professional Maintenance

Consider hiring a professional contractor for periodic maintenance and reapplication of coatings or finishes, especially for large or complex garage floors. Professional maintenance services can ensure that your floor remains in optimal condition and extends its lifespan. Be sure to choose a reputable contractor with experience in garage floor maintenance and restoration.

Garage Build Part 13 – Preparing the floor to pour concrete

How I upgraded my garage floor (HUGE Difference) – YouTube

DIY Epoxy Garage Floor Tutorial – How to make your garage look

How to improve garage floor look and color?

Epoxy Floor Coating: All You Need To Know About Epoxy Coating

Related Posts: