The floor surface is so easy to keep and also you can wipe it clean like sparkling countertops. You are urged to take a look at the numerous colors at the disposal of theirs. Are you tired of that boring old gray concrete in your workshop, garage or maybe rumpus room? Cover it up and make it appear clear with something that’s sturdy enough to withstand the frequent beating that floors take.

Images about Liquid Epoxy Resin Flooring

Liquid Epoxy Resin Flooring

Plus you will discover a wide variety of basic epoxy chemicals which can be utilized in order to develop epoxy flooring. news that is Good is, you can constantly customize your floor as per the preferences of yours. An epoxy floor is created when a protective resin is used over the top part of an existing concrete slab. Adding colored silica tends to make the floor appealing.

How to do Epoxy Floors – STEP BY STEP GUIDE – S3E3 – YouTube

Epoxy floors are easy to clean and are amazingly reluctant to bacteria. In earlier days, epoxies floor coatings were restricted to merchandise stores, but with the arrival of technology, they have become a pattern for flooring should have in industries, hospitals, garages, warehouses, factories, showrooms, as well as federal government facilities brightening up the floors.

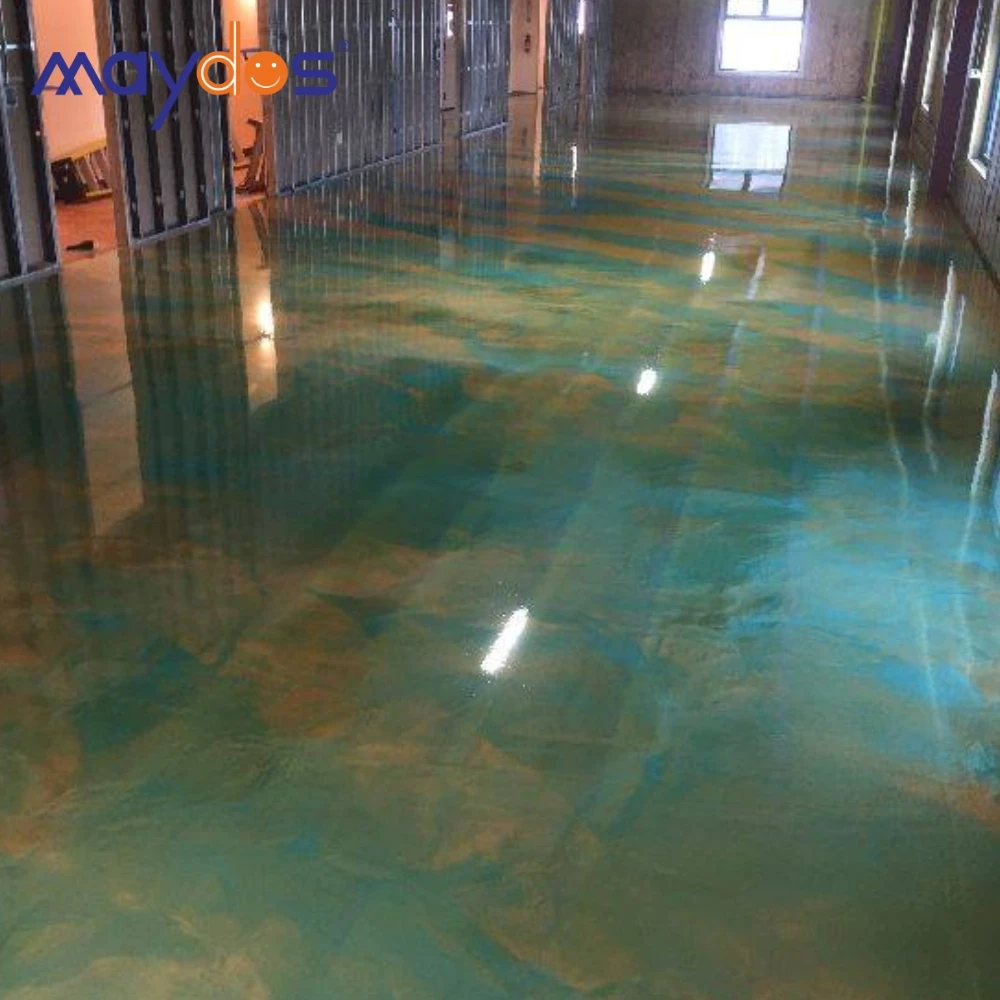

China Crystal Clear Liquid Metallic Epoxy Resin Flooring Coating

How To Do Amazing Metallic Epoxy Floor!

Liquid epoxy resin flooring – WATER-BASED MATTE – Watco Industrial

Maydos 3d Chemicals Liquid Epoxy Resin Flooring Paint – Buy 3d

DIY Designer Epoxy Resin Floor : 7 Steps (with Pictures

81 New Liquid floors ideas epoxy floor, flooring, concrete floors

Liquid Marble – Epoxy Coat Texas – Houston Epoxy Flooring

Liquid epoxy resin flooring – HIGH BUILD 100 – Watco Industrial

Do-It-Yourself Epoxy Floor Coating

Crystal Clear Liquid Metallic Flooring Coating, Marble Effect Floor, Resin Floors – Brown Glitter Floor #Resinfloor #Epoxyfloor Coating Epoxy Resin

Liquid epoxy resin floor covering – WATCO FLOWTOP® GREY – WATCO

Understanding the Pros and Cons of Epoxy Floors

Related Posts:

- White Epoxy Garage Floor

- Epoxy Gloss Floor Paint

- Epoxy Concrete Floor Covering

- Thick Epoxy Floor Coating

- Epoxy Paint Floor Finish

- Epoxy Floor Coating For Basement

- White Metallic Epoxy Floor

- Metallic Epoxy Floor Installation

- Red Epoxy Floor

- Clear Epoxy Shower Floor

Introduction

Liquid epoxy resin flooring is a type of flooring solution that has become increasingly popular due to its durability, attractive finish, and cost effectiveness. It is made up of two-component systems, epoxy resins, and hardeners, and is often used in commercial and industrial settings. It is also becoming more commonly used in residential settings as well due to the wide variety of finishes, colors, and textures available. In this article, we will discuss the advantages of liquid epoxy resin flooring and how it can be installed in various applications.

Advantages of Liquid Epoxy Resin Flooring

Liquid epoxy resin flooring offers a number of benefits for both commercial and residential settings. It is extremely durable and can withstand heavy traffic, making it an ideal choice for areas that experience high levels of foot traffic or heavy machinery. It is also resistant to most chemical spills and oils, making it an ideal choice for industrial settings. Additionally, it is non-porous, which means that it does not absorb liquids or other contaminants, making it easy to clean and maintain. The surface finish of liquid epoxy resin flooring also makes it attractive in both commercial and residential settings due to its glossy surface and wide variety of colors, textures, and designs available. Additionally, it is relatively cost effective compared to other types of flooring solutions.

Installation Process

The installation process for liquid epoxy resin flooring requires a few steps to ensure a smooth and seamless finish. First, the area must be cleaned thoroughly to remove any dirt or debris. Once the area has been cleaned, the substrate must be prepared by grinding down any rough edges and filling any cracks or holes with a patching compound. Next, the epoxy resin and hardener must be mixed together according to the manufacturer’s instructions before being spread over the substrate using a trowel or squeegee. Once the mixture has been spread evenly across the substrate, it must be allowed to cure before any additional layers can be added.

Additional Layers

Once the first layer has cured sufficiently, additional layers may be added depending on the desired effect. These layers may include decorative flakes, colored quartz sand, or even metallic particles. Each layer will require a different curing time depending on the mix used. Once all of the layers have been applied and cured sufficiently, a topcoat may be applied to protect the surface and enhance its overall appearance.

FAQs about Liquid Epoxy Resin Flooring

Q: What are the advantages of liquid epoxy resin flooring?

A: Liquid epoxy resin flooring offers a number of advantages including extreme durability, resistance to most chemicals and oils, non-porous surface finish making it easy to clean and maintain, attractive finish in various colors, textures, and designs available, and relatively cost effective compared to other types of flooring solutions.

Q: What is involved in the installation process?

A: The installation process for liquid epoxy resin flooring involves cleaning the area thoroughly to remove any dirt or debris; preparing the substrate by grinding down any rough edges and filling any cracks or holes with a patching compound; mixing the epoxy resin and hardener together according to manufacturer’s instructions; spreading the mixture over the substrate using a trowel or squeegee; allowing it to cure; adding additional layers such as decorative flakes, colored quartz sand, or metallic particles; allowing each layer to cure; and finally applying a topcoat for protection and enhanced appearance.

Q: How long does it take for liquid epoxy resin flooring to cure?

A: The curing time for liquid epoxy resin flooring depends on several factors including temperature, humidity levels, thickness of application, and type of mix used. Generally speaking however, it will take approximately 24-48 hours for each layer to cure sufficiently before additional layers may be added.

Conclusion

In conclusion, liquid epoxy resin flooring is an ideal solution for areas that experience high levels of foot traffic or heavy machinery due to its extreme durability and resistance to most chemical spills and oils. Additionally, it is attractive in both commercial and residential settings due to its glossy surface finish and wide variety of colors, textures, and designs