Polished concrete flooring is one of the least expensive options as compared to other information used for flooring nowadays. It really works with the lime content in the floor it is quite unpredictable but generally comes out looking quite good. It is in addition a good idea to survey the concrete floors often and remove some extra substances, like stickers or gum, and examine it for damage.

Images about Typical Concrete Floor Construction

Typical Concrete Floor Construction

The benefits that an individual can purchase from the polished concrete floors are extremely numerous and several of them include the point that the polished concrete floors present a real very low cost solution to the thought of flooring as a well as offering a great option in conditions of eco-friendly alternatives.

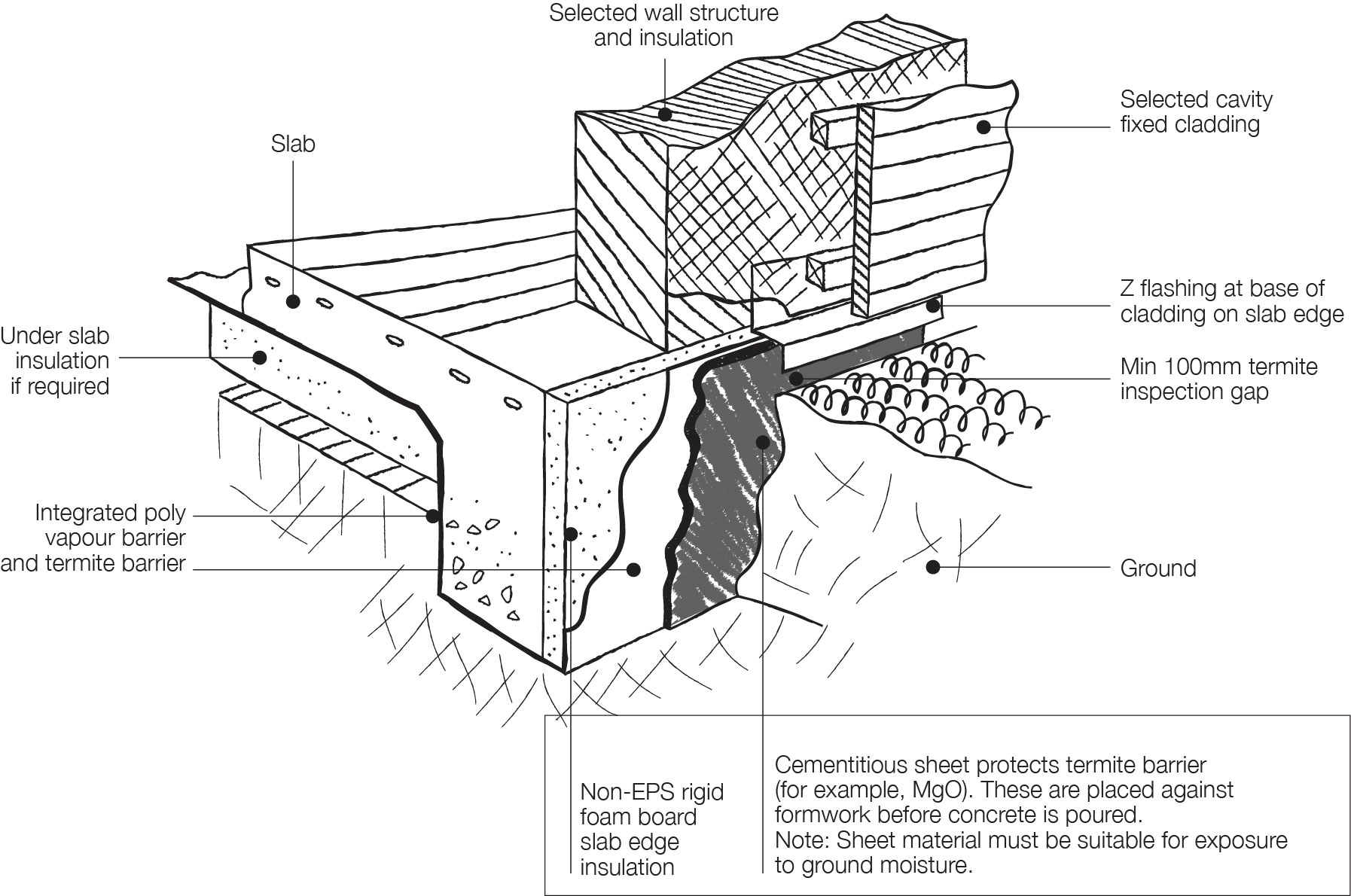

Concrete slab floor construction BRANZ Renovate

Developing with concrete countertops outdoors is likewise appealing because of the basic maintenance of theirs and vast style flexibility. Concrete polishing is the finish of preference for the majority of owners of new and present concrete floors. Polished concrete is seamless, leaving no place for dust mites to gather as well as expose the bacteria which may be caught between floorboards and tiles.

Concrete floor – Podovi Grupa

Building Guidelines Concrete Floors, Slabs

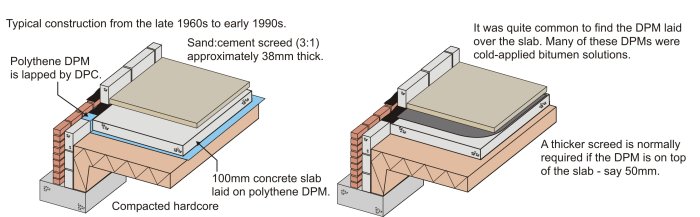

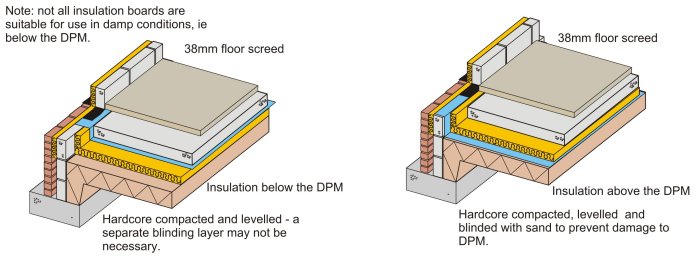

Evolution of Building Elements

Suspended Floors – All You Need To Know – Thermohouse

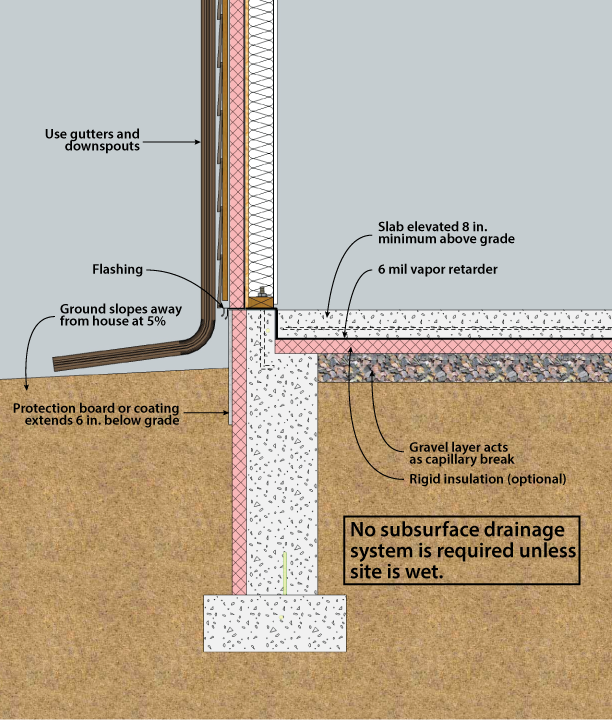

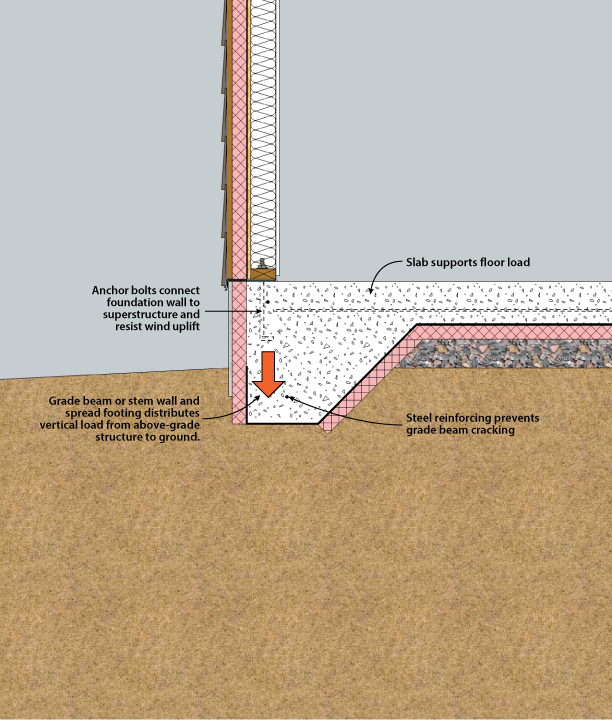

DOE Building Foundations Section 4-1

Building Guidelines Drawings. Section B: Concrete Construction

Evolution of Building Elements

DOE Building Foundations Section 4-1

Building Guidelines Concrete Floors, Slabs

Concrete slab floors YourHome

Building Guidelines Drawings. Section B: Concrete Construction

What Is Floating Slab Floating Slab Construction How to Build a

Related Posts:

- Acid Wash Concrete Floor Colors

- Concrete Floor Thickness For A Garage

- Concrete Floor For Bathroom

- Interior Concrete Floor Ideas

- Kitchen Stained Concrete Floors

- Concrete Floor Tile Thickness

- How To Stain Concrete Floors DIY

- DIY Concrete Floor Grinding

- Concrete Floor Damage

- Faux Stained Concrete Floors

Typical Concrete Floor Construction

Concrete floors are one of the most common types of flooring found in homes and commercial buildings. While they are durable and resilient, they require careful attention to detail in order to ensure they are properly constructed and installed. To understand the typical concrete floor construction process, it is important to be familiar with the materials used, techniques employed, and the steps taken for a successful outcome.

Materials Used

The materials used for typical concrete floor construction include concrete mix, reinforcing mesh, formwork, and sealant. The concrete mix typically consists of Portland cement, sand, and gravel. The type of concrete mix used depends on the desired strength and durability of the finished product. Reinforcing mesh is used to provide additional strength to the concrete and can be made from steel or plastic. Formwork is used to shape the concrete during the pouring process and is usually made from wood or metal. Sealant is applied after the concrete has been poured and cured to protect it from moisture damage.

Techniques Employed

In order to ensure a quality finished product, there are several techniques employed during typical concrete floor construction. These include compaction, curing, reinforcing, and sealing. Compaction is done after the concrete has been poured and involves tamping down the surface to level out any air pockets or voids. Curing involves allowing the concrete time to harden and develop its full strength before it can be walked on or covered with carpet or tile. Reinforcing involves placing reinforcing mesh within the concrete mix to provide additional strength and prevent cracking. Sealing involves applying a sealant over the surface of the concrete once it has been poured, cured, and reinforced to protect it from moisture damage.

Steps Taken for a Successful Outcome

The steps taken for a successful outcome when constructing a typical concrete floor involve preparation, pouring, curing, reinforcing, sealing, and finishing. Preparation includes removing any existing flooring and preparing the surface for the pour by smoothing out any rough spots or irregularities. Pouring involves mixing up the concrete mix according to manufacturer’s instructions and pouring it into place on the prepared surface. Curing involves allowing the concrete time to harden before walking on it or covering it with carpet or tile. Reinforcing involves laying down reinforcing mesh as needed within the pour to provide additional strength and prevent cracking. Sealing involves applying a sealant over the cured concrete to protect it from moisture damage. Finishing involves adding any desired decorative features such as staining or polishing for a beautiful finished look.

FAQs about Typical Concrete Floor Construction

Q: What materials are used for typical concrete floor construction?

A: The materials used for typical concrete floor construction include concrete mix, reinforcing mesh, formwork, and sealant. The type of concrete mix used depends on the desired strength and durability of the finished product. Reinforcing mesh can be made from steel or plastic while formwork is usually made from wood or metal. Sealant is applied after the concrete has been poured and cured to protect it from moisture damage.

Q: What techniques are employed during typical concrete floor construction?

A: Techniques employed during typical concrete floor construction include compaction, curing, reinforcing, and sealing. Compaction is done after the concrete has been poured and involves tamping down the surface to level out any air pockets or voids. Curing involves allowing the concrete time to harden before it can be walked on or covered with carpet or tile. Reinforcing involves placing reinforcing mesh within the pour to provide additional strength and prevent cracking. Sealing involves applying a sealant over the surface of the cured concrete to protect it from moisture damage.

Q: What are steps taken for a successful outcome when constructing a typical concrete floor?

A: Steps taken for a successful outcome when constructing a typical concrete floor involve preparation, pouring, curing, reinforcing, sealing, and finishing. Preparation includes removing any existing flooring and preparing the surface for the pour by smoothing out any rough spots or irregularities. Pouring involves mixing up the concrete mix according to manufacturer’s instructions and pouring it into place on the prepared surface. Curing involves allowing the concrete time to harden before walking on it or covering it with