Importance of Installing a Vapor Barrier Under Concrete Basement Floor

The importance of installing a vapor barrier under a concrete basement floor cannot be overstated. This crucial step helps to prevent moisture from seeping through the concrete and causing damage to the basement and the rest of the building.

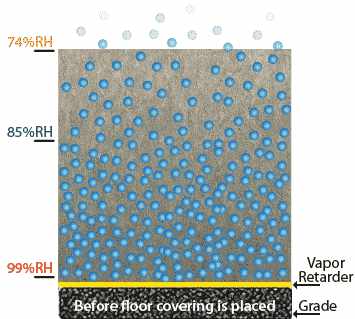

Moisture is a common problem in basements, as the ground surrounding the foundation can contain a significant amount of water. Without a vapor barrier, this moisture can gradually seep through the porous concrete floor, leading to a damp environment. This dampness can promote the growth of mold and mildew, which can have detrimental effects on both the structural integrity of the building and the health of its occupants.

By installing a vapor barrier, the concrete basement floor is protected from moisture intrusion. The barrier acts as a barrier to prevent water vapor from passing through the concrete and into the basement. This helps to maintain a dry environment, reducing the risk of mold and mildew growth.

In addition to preventing moisture-related issues, a vapor barrier can also contribute to energy efficiency. When moisture is able to infiltrate the basement, it can increase the humidity levels in the entire building. This can make it more difficult and costly to regulate the temperature, as the HVAC system will have to work harder to remove the excess moisture from the air. By installing a vapor barrier, the basement remains dry, reducing the strain on the HVAC system and potentially lowering energy costs.

Furthermore, a vapor barrier can also provide protection against radon gas. Radon is a naturally occurring radioactive gas that can seep into buildings through cracks in the foundation. It is a known carcinogen and can pose serious health risks when present in high concentrations. By installing a vapor barrier, the likelihood of radon gas entering the basement is reduced, helping to safeguard the health and safety of the occupants.

How Vapor Barriers Protect Against Moisture and Mold in Basement Floors

A vapor barrier under a concrete basement floor is a crucial component in protecting against moisture and mold. Moisture is a common issue in basements, as they are located below ground level and are susceptible to water seepage from the surrounding soil. This moisture can penetrate through the concrete floor, leading to dampness and potential mold growth.

A vapor barrier acts as a barrier between the concrete floor and the moisture in the soil. It is typically made of a thick, durable plastic material that is resistant to moisture. When properly installed, the vapor barrier prevents moisture from seeping into the concrete, keeping the basement floor dry.

By preventing moisture from entering the concrete, a vapor barrier also helps to prevent mold growth. Mold requires moisture to thrive, and a damp basement floor can provide the perfect environment for mold spores to grow and multiply. Mold not only damages the structure of the basement but can also pose serious health risks to individuals living in the home.

In addition to protecting against moisture and mold, a vapor barrier can also improve the overall comfort of a basement. Keeping the floor dry, helps to reduce musty odors and the feeling of dampness that is often associated with basements.

Proper installation of a vapor barrier is essential for its effectiveness. It should be installed directly under the concrete floor, covering the entire surface area. All seams and joints should be properly sealed to ensure a tight and continuous barrier.

Types of Vapor Barriers for Concrete Basement Floors Pros and Cons

Polyethylene Sheets

Polyethylene sheets are one of the most common types of vapor barriers used for concrete basement floors. These sheets are typically made from a thick plastic material and are laid directly on the subfloor before pouring the concrete.

Pros:

– Easy installation: Polyethylene sheets are easy to install as they can be simply rolled out over the subfloor.

– Cost-effective: Compared to other types of vapor barriers, polyethylene sheets are relatively inexpensive.

– Effective moisture barrier: Polyethylene sheets provide a high level of moisture resistance, preventing water vapor from seeping through the concrete.

Cons:

– Vulnerable to tears: Polyethylene sheets can be easily damaged during installation or construction activities, leading to compromised effectiveness.

– Limited durability: Over time, polyethylene sheets may deteriorate or become brittle, reducing their effectiveness as a vapor barrier.

– Lack of breathability: These sheets do not allow moisture to escape from the concrete, which can potentially lead to moisture accumulation and mold growth.

Rubber Membranes

Rubber membranes are another popular option for vapor barriers in concrete basement floors. These membranes are typically made from synthetic rubber or a rubberized asphalt compound and are applied directly to the subfloor.

Pros:

– Excellent durability: Rubber membranes are highly durable and resistant to tears or punctures, ensuring long-term effectiveness.

– Flexible and easy to work with: These membranes can easily conform to irregular surfaces, making them ideal for basement floors with uneven subfloors.

– Superior moisture resistance: Rubber membranes provide a high level of moisture resistance, preventing water vapor from permeating the concrete.

Cons:

– Higher cost: Rubber membranes are generally more expensive than polyethylene sheets, increasing the overall cost of installation.

– Limited breathability: Similar to polyethylene sheets, rubber membranes do not allow moisture to escape, potentially leading to moisture accumulation and mold growth.

– Installation complexities: Proper installation of rubber membranes may require professional expertise, increasing the complexity and cost of the project.

Step-by-Step Guide to Installing a Vapor Barrier Under Concrete Basement Floor

Installing a vapor barrier under a concrete basement floor is an essential step in preventing moisture and water damage. This guide will provide you with a step-by-step process to ensure the proper installation of the vapor barrier.

1. Prepare the Basement Floor:

Before installing the vapor barrier, it is crucial to clean and prepare the basement floor thoroughly. Remove any existing flooring or debris, and make sure the surface is clean and dry.

2. Repair Any Cracks or Holes:

Inspect the basement floor for any cracks or holes. Fill these imperfections with a suitable concrete patching compound and allow it to dry completely. This step is crucial to prevent moisture from seeping through and compromising the effectiveness of the vapor barrier.

3. Choose the Right Vapor Barrier:

Select a high-quality vapor barrier specifically designed for basement floors. Look for a product that has a high puncture resistance and low permeability to moisture. Measure the dimensions of your basement floor to determine the amount of vapor barrier material needed.

4. Lay the Vapor Barrier:

Roll out the vapor barrier across the entire basement floor, ensuring that it extends up the walls by at least 6 inches. Overlap the seams of the vapor barrier by 6-12 inches and use heavy-duty tape or adhesive to secure the joints. Trim any excess material along the edges of the floor.

5. Secure the Vapor Barrier:

To ensure the vapor barrier remains in place, anchor it to the concrete floor using a suitable adhesive or tape. This will prevent any shifting or movement during the installation of subsequent flooring layers.

6. Test the Vapor Barrier:

Once the vapor barrier is installed, conduct a simple test to check for any leaks or gaps. Pour a small amount of water onto the vapor barrier and observe if it forms beads or if it is absorbed. If there are any signs of leakage, address them immediately before proceeding with further construction.

7. Install Additional Flooring Layers:

After successfully installing the vapor barrier, you can proceed with the installation of additional flooring layers. Follow the manufacturer’s instructions for installing any underlayment, insulation, or finished flooring materials.

Polyethylene Under Concrete Slabs – GreenBuildingAdvisor

Concrete Vapor Barriers for Under Slabs – Concrete Network

White Paper) Under Slab Vapor Retarders/Barriers ASTM E1745 and

Underslab Retrofits: Sealing Slabs WATERPROOF! Magazine

Concrete Floor Problems Building Science Corporation

Concrete Vapor Barriers: The Pros u0026 Cons of Getting The Vapors

The Best Moisture Barrier for Protecting Concrete Slabs and Floors

The Importance of a Vapor Barrier for Below-Grade Insulation

How to Install an Under-Slab Vapor Barrier Pro Builder

Related Posts:

- Concrete Flooring Options For Basement

- Sill Gasket For Basement Floor

- Vinyl Flooring In Basement Pros And Cons

- How Thick Are Basement Floors

- Thermal Break Basement Floor

- Interlocking Rubber Floor Tiles For Basement

- Remove Water From Basement Floor

- Types Of Basement Floor Drains

- Basement Floor Cement Sealer

- How To Lower Your Basement Floor