There are a number of diverse techniques you can apply to concrete flooring to generate gorgeous decorative floors ideal for both the office of yours and your home. If you desire to get a tank of it, as soon as poured, concrete should bring it. With acid stained concrete floors, you've alternatives available to meet your design must have. With acid stained concrete floors, you've alternatives available to meet your design must have. With acid stained concrete floors, you've alternatives available to meet your design must have. With acid stained concrete floors, you've alternatives available to meet your design must have.

Images about Concrete Floor Over Plywood

Concrete Floor Over Plywood

Today's concrete for flooring comes in a wide variety of colors that are different, and it is feasible to include in a number of different stone and other materials to produce a polished concrete floor a thing of beauty. Concrete flooring has appeal that is great for all keen on eco-friendly construction.

Installing Plywood Flooring Over Concrete ⋆  ThePlywood.com

ThePlywood.com

Staining concrete flooring is a thing that you can conveniently do yourself or perhaps pay an expert to do if you want a more complex decorative concrete strategy. The benefits of polished concrete floors are extremely numerous and for any person aiming to have good flooring, it is wise not to look any further than the polished flooring surfaces.

How To install Concrete Over plywood sub-floor?

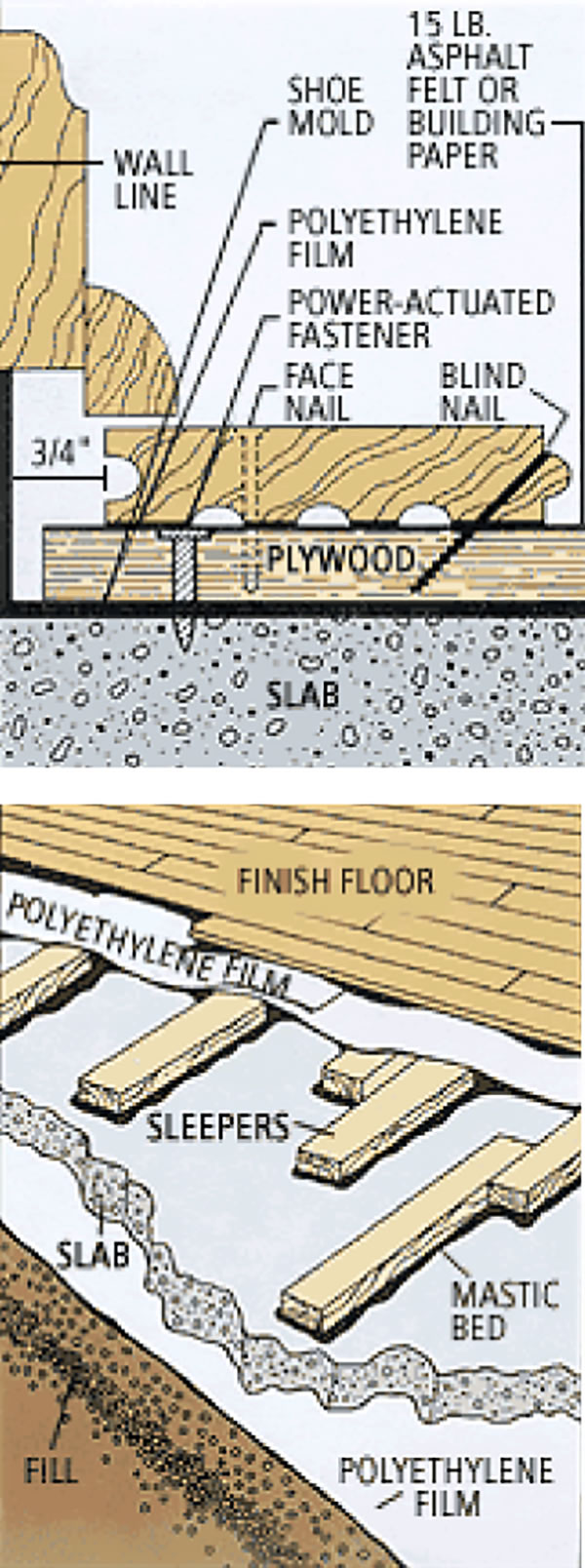

How-to install a wood subfloor over concrete RONA

Framing Sleeper Floors Better Homes u0026 Gardens

Concrete Over Plywood – Upgrade Wood Subfloor Into Concrete

Concrete Over Plywood – Upgrade Wood Subfloor Into Concrete

Concrete over a plywood subfloor with 16″ on center floor joists

How to Install a Barn Board Floor over Concrete Tutorial DIY

Make Concrete / Cement Floor Over OSB Wood Subfloor

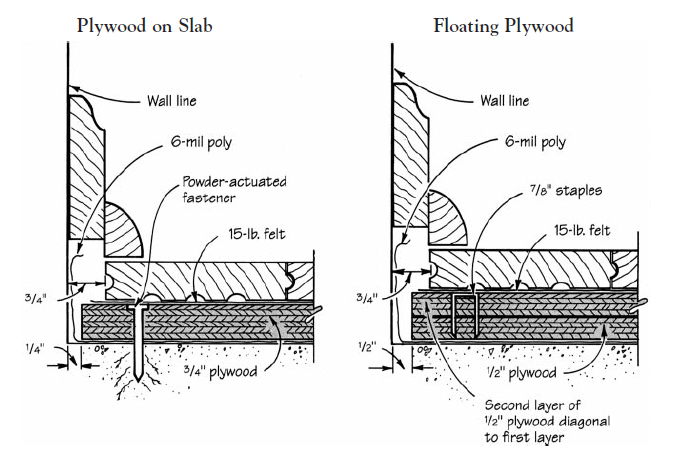

Installing a Hardwood Floor Over a Concrete Slab – American

Plywood Sub Floors, Concrete Sub Floors, Sub Floor Demolition

Breakfast Room Progress – Plywood Subfloor Installed Over Concrete

Qu0026A: Solid Wood Floors Over Concrete Slabs JLC Online

Related Posts:

- Polished Concrete Floors For Patios

- White Concrete Floor Tiles

- Acid Wash Concrete Floor Colors

- Concrete Floor Thickness For A Garage

- Concrete Floor For Bathroom

- Interior Concrete Floor Ideas

- Kitchen Stained Concrete Floors

- Concrete Floor Tile Thickness

- How To Stain Concrete Floors DIY

- DIY Concrete Floor Grinding

Introduction

Concrete floors over plywood are becoming increasingly popular as a flooring option. They provide a durable, low-maintenance surface that is easy to install and can be customized to fit any design aesthetic. Concrete is also a very cost-effective flooring option as it is relatively inexpensive and requires minimal upkeep. This article will discuss the benefits of concrete floor over plywood, the different types of concrete available, and tips for installation.

Benefits of Concrete Floor Over Plywood

Concrete floors over plywood offer many advantages over traditional flooring materials such as hardwood, tile, or linoleum. One of the primary benefits of concrete is its durability. Concrete is extremely resistant to wear and tear, making it an ideal choice for high traffic areas such as living rooms and hallways. Additionally, concrete floors are fire-resistant and less likely to warp or crack when exposed to moisture.

Another benefit of concrete flooring is its low maintenance requirements. Unlike wood or tile, concrete does not need to be refinished or resealed periodically. It also does not require a sealant to protect against water damage or staining. This makes concrete an ideal choice for busy households who don’t have time for regular upkeep.

Finally, concrete floors are extremely customizable. There are a variety of colors and textures available, allowing homeowners to create a unique look that reflects their personal style. Additionally, concrete can be stained or painted to create a one-of-a-kind design.

Types of Concrete Available

When choosing a concrete floor, there are a variety of types available. The most common type of concrete is Portland cement, which is made from a mixture of cement, sand, and water. This type of concrete is usually used for interior applications such as floors and countertops. Self-leveling concrete is another popular option as it provides an even surface with minimal preparation time. This type of concrete can be used for both interior and exterior applications. Additionally, there are various types of colored and textured concretes that can be used to create a unique look.

Tips for Installation

Installation of a concrete floor over plywood requires some preparation before beginning the project. First, the plywood must be leveled and sealed to prevent water damage and mold growth. Additionally, any joints in the plywood should be filled with caulk or another filler material to prevent cracking in the finished product. Once the plywood has been prepared, it’s time to mix the concrete according to the manufacturer’s instructions and spread it evenly over the surface using a trowel or other tool. Finally, the concrete should be left to cure for at least 24 hours before walking on it or applying any type of sealant or stain.

FAQs

Q: What are the benefits of installing a concrete floor over plywood?

A: Installing a concrete floor over plywood offers many benefits including durability, low maintenance requirements, fire resistance, customizability, and cost-effectiveness when compared to other flooring options such as hardwood or tile.

Q: What types of concrete are available?

A: The most common type of concrete is Portland cement which is made from a mixture of cement, sand, and water. Other options include self-leveling concrete which provides an even surface with minimal preparation time and colored or textured concretes which can be used to create a unique look.

Q: What steps should I take before installing a concrete floor?

A: Before installing a concrete floor over plywood, the plywood should be leveled and sealed to prevent water damage and mold growth. Additionally, any joints in the plywood should be filled with caulk or another filler material to prevent cracking in the finished product. Once this has been done, it’s time to mix the concrete according to the manufacturer’s instructions and spread it evenly over the surface using a trowel or other tool before allowing it to cure for at least 24 hours before walking on it or applying any type of sealant or stain.