What is Epoxy Resin Floor Screed?

Epoxy resin floor screed is a type of flooring system that is composed of epoxy resin and a variety of other materials. It is a self-leveling compound that is applied to the floor surface to create a smooth, durable, and seamless finish. Epoxy resin floor screed is widely used in commercial, industrial, and residential settings due to its numerous advantages.

Epoxy resin floor screed is a high-performance flooring solution that offers excellent resistance to chemicals, abrasion, impact, and heavy loads. It is commonly used in areas that require a strong and durable floor, such as warehouses, factories, garages, and hospitals. The material is known for its ability to withstand heavy traffic and harsh environments, making it a popular choice for commercial and industrial facilities.

One of the key features of epoxy resin floor screed is its seamless and hygienic surface. Unlike traditional flooring options, such as tiles or carpet, epoxy resin floor screed does not have any joints or grout lines where dirt, bacteria, or liquids can accumulate. This makes it easy to clean and maintain, making it an ideal choice for areas that require high levels of cleanliness, such as kitchens, laboratories, and healthcare facilities.

Epoxy resin floor screed is also highly customizable in terms of color and design. It can be mixed with pigments to create a wide range of colors, allowing for endless design possibilities. Additionally, patterns, logos, and graphics can be incorporated into the floor, making it a creative and visually appealing option for retail spaces, showrooms, and entertainment venues.

In terms of installation, epoxy resin floor screed requires professional expertise and proper surface preparation. The existing floor needs to be thoroughly cleaned, repaired, and primed before the resin is applied. The material is then poured or troweled onto the surface and left to cure. The curing time can vary depending on the specific product, but generally, it takes a few days for the floor to fully harden and be ready for use.

Epoxy resin floor screed offers a durable, hygienic, and visually appealing flooring solution for a wide range of applications. Its versatility, resistance to wear and tear and ease of maintenance make it a popular choice among homeowners and businesses alike. Whether you are looking for a strong and reliable floor for an industrial facility or a stylish and seamless finish for a retail space, epoxy resin floor screed is a versatile option worth considering.

Benefits of Using Epoxy Resin Floor Screed

Epoxy resin floor screed offers a multitude of benefits that make it a popular choice for various applications. From its durability and resistance to its aesthetic appeal and low maintenance requirements, there are several advantages to using epoxy resin floor screed in both commercial and residential settings.

One of the primary benefits of epoxy resin floor screed is its exceptional durability. It is highly resistant to chemicals, impact, abrasion, and heavy loads, making it ideal for areas that experience high foot traffic or the movement of heavy machinery. This durability ensures that the floor remains intact and maintains its appearance even under harsh conditions.

Another advantage of epoxy resin floor screed is its seamless and hygienic surface. Unlike traditional flooring options, such as tiles or carpet, epoxy resin floor screed does not have any joints or grout lines where dirt, bacteria, or liquids can accumulate. This makes it easy to clean and maintain, reducing the risk of bacteria growth and ensuring a hygienic environment.

Epoxy resin floor screed is highly resistant to staining, which is particularly beneficial in areas prone to spills or accidents. The surface can be easily cleaned with mild detergents and water, without leaving any permanent marks. This stain resistance ensures that the floor maintains its appearance over time, even in high-traffic areas.

In addition to its functional benefits, epoxy resin floor screed offers aesthetic advantages as well. The material can be customized in terms of color, texture, and design, allowing for endless creative possibilities. This versatility makes it a popular choice for architects, designers, and homeowners who want to achieve a unique and visually appealing floor.

Furthermore, epoxy resin floor screed is known for its quick installation process. With the help of professional installers, the material can be applied efficiently, reducing downtime and disruptions to daily activities. This is particularly advantageous in commercial settings where time is of the essence.

How to Apply Epoxy Resin Floor Screed

Applying epoxy resin floor screed requires careful planning and proper execution to ensure a successful and long-lasting result. We will guide you through the step-by-step process of applying epoxy resin floor screed, from surface preparation to the final curing stage.

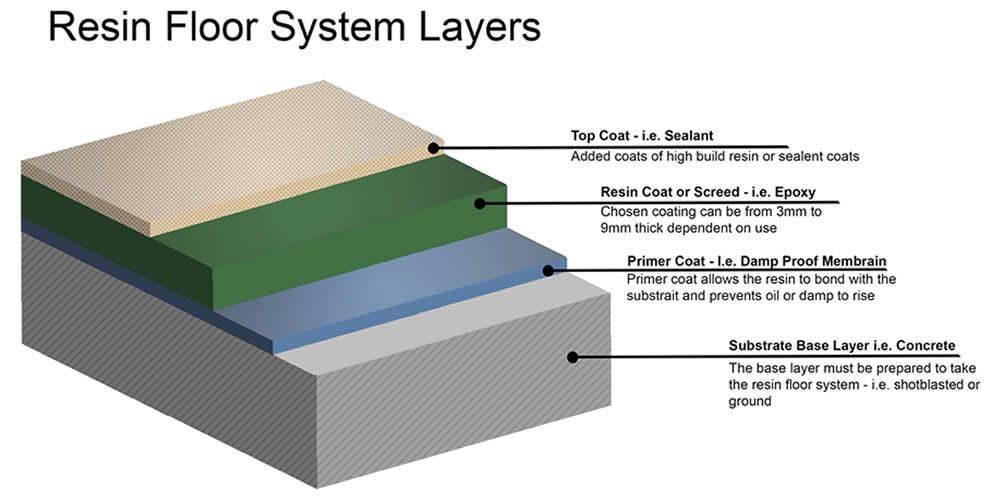

The first step in applying epoxy resin floor screed is to prepare the surface. This involves thoroughly cleaning the floor to remove any dirt, dust, grease, or previous coatings. Any cracks or damages should be repaired, and the surface should be sanded or shot-blasted to create a rough texture for better adhesion.

Once the surface is prepared, the next step is to apply a primer. The primer helps to enhance adhesion and prevent the formation of air bubbles. It is important to choose a primer that is compatible with the epoxy resin floor screed you are using and follow the manufacturer’s instructions for application.

After the primer has dried, it is time to mix the epoxy resin floor screed. Follow the manufacturer’s instructions to mix the components in the correct proportions. It is essential to ensure thorough mixing to achieve a consistent and homogenous mixture.

Using a trowel or a roller, apply the epoxy resin floor screed to the prepared surface. Start in one corner and work your way towards the exit to avoid stepping on the freshly applied material. Ensure an even and consistent thickness throughout the floor.

Once the epoxy resin floor screed is applied, use a spiked roller to remove any air bubbles and create a smooth surface. This step is crucial to achieving a seamless and professional finish. It is recommended to work in small sections to ensure proper coverage and eliminate any imperfections.

After applying the epoxy resin floor screed, allow it to cure according to the manufacturer’s instructions. This typically involves waiting for a specific period, usually a few days, for the floor to fully harden and become ready for use. Avoid walking or placing heavy objects on the floor during the curing process.

Finally, once the floor is fully cured, conduct a thorough inspection to ensure that the surface is free of any defects or imperfections. If necessary, touch up any areas that require additional attention. Regular maintenance and cleaning will help to preserve the appearance and longevity of the epoxy resin floor screed.

Maintenance and Care Tips for Epoxy Resin Floor Screed

Proper maintenance and care are essential for preserving the appearance and longevity of epoxy resin floor screed. Here are some valuable tips on how to maintain and care for your epoxy resin floor screed to ensure its durability and aesthetic appeal.

Regular cleaning is crucial for maintaining the cleanliness and appearance of epoxy resin floor screed. Sweep or vacuum the floor regularly to remove loose dirt and debris. Use a mild detergent and warm water to mop the floor, ensuring that the cleaning solution is compatible with epoxy resin. Avoid using abrasive cleaners or tools that may scratch the surface.

To protect the epoxy resin floor screed from scratches and damage, use protective mats or rugs in high-traffic areas or under heavy furniture. This will help distribute the weight and reduce the impact on the floor. Avoid dragging heavy objects across the floor to prevent scratches.

In areas where the floor is exposed to chemicals or spills, promptly clean up any spills to prevent staining or damage. Use a soft cloth or mop to absorb the spill and clean the affected area with a suitable cleaning solution. Avoid using harsh chemicals that may degrade the epoxy resin.

Regularly inspect the epoxy resin floor screed for any signs of wear or damage. If you notice any cracks, chips, or areas of peeling, address them promptly to prevent further deterioration. Depending on the severity of the damage, you may need to consult a professional for repairs.

To maintain the shine and luster of the epoxy resin floor screed, periodic reapplication of a topcoat may be necessary. Consult the manufacturer’s recommendations for the appropriate frequency of reapplication. This will help protect the floor from UV rays, maintain its appearance, and extend its lifespan.

Avoid exposing the epoxy resin floor screed to extreme temperatures. Rapid temperature changes can cause the material to expand or contract, leading to cracks or other forms of damage. Use proper insulation or temperature control measures in areas where temperature fluctuations are common.

Different Applications of Epoxy Resin Floor Screed

Epoxy resin floor screed is a versatile flooring solution that can be applied in various settings. Let’s explore the different applications of epoxy resin floor screed and how it can be used to enhance both the functionality and aesthetics of different spaces.

In industrial settings, epoxy resin floor screed is commonly used due to its exceptional durability and resistance to chemicals, abrasion, and heavy loads. It provides a seamless and hygienic surface that is easy to clean, making it ideal for warehouses, manufacturing facilities, and workshops.

Epoxy resin floor screed is also popular in commercial spaces such as retail stores, showrooms, and exhibition halls. Its customizable design options, including a wide range of colors and the ability to incorporate logos and graphics, make it an attractive choice for creating visually appealing and unique flooring finishes.

In healthcare facilities, epoxy resin floor screed is a preferred choice due to its hygienic properties. Its seamless surface and resistance to stains and bacteria growth make it suitable for areas such as hospitals, clinics, laboratories, and pharmaceutical facilities.

Epoxy resin floor screed is also used in residential applications, particularly in garages, basements, and utility rooms. Its durability, ease of maintenance, and resistance to chemicals and stains make it an excellent choice for areas that require a robust and long-lasting flooring solution.

Sports facilities and recreational areas can benefit from epoxy resin floor screed due to its impact resistance and slip-resistant properties. It is commonly used in gyms, fitness centers, indoor sports courts, and swimming pool surrounds, providing a safe and durable surface for various activities.

In commercial kitchens and food processing areas, epoxy resin floor screed is favored due to its seamless and hygienic surface. It can withstand high temperatures, heavy foot traffic, and exposure to food spills and cleaning chemicals, making it an ideal choice for maintaining a clean and safe environment.

Epoxy Resin Screed – CG Flooring Systems

Industrial Floorings FAQs PSC Flooring Ltd. Epoxy Flooring

Polyurethane Resin Screed – CG Flooring Systems

Epoxy Resin Screed and Urethane Mortar Screed Applications

Trowel Finished Resin Floor Screeds – Type 6 u0026 8 – NCC Resin Flooring

The Ultimate Introduction to Epoxy Flooring Flowcrete

Related Posts: