Introduction to Lightweight Concrete Flooring Systems

Lightweight concrete flooring systems have gained significant popularity in recent years due to their unique properties and advantages. This type of flooring is composed of lightweight aggregates, such as expanded clay, shale, or slate, which replace the traditional heavy aggregates like gravel and stone. As a result, lightweight concrete flooring offers a range of benefits, including reduced dead load, improved thermal insulation, and enhanced soundproofing capabilities.

- The Importance of Lightweight Concrete Flooring. In various construction projects, the weight of the flooring plays a crucial role. Heavy flooding can put excessive stress on the overall structure, leading to potential issues like cracks, settlement, or even collapse. Lightweight concrete flooring helps address this concern by significantly reducing the load on the structure. This not only ensures the safety and stability of the building but also allows for more design flexibility.

- Enhanced Thermal Insulation and Energy Efficiency. Another significant advantage of lightweight concrete flooring systems is their superior thermal insulation properties. The lightweight aggregates used in the concrete composition create air pockets, which act as insulators, reducing heat transfer through the floor. This results in improved energy efficiency, reduced heating and cooling costs, and a more comfortable indoor environment.

- Acoustic Benefits of Lightweight Concrete Flooring. Noise pollution is a common concern in both residential and commercial buildings. Lightweight concrete flooring systems help mitigate this issue by providing excellent soundproofing capabilities. The air pockets within the lightweight aggregates absorb and dampen sound, reducing noise transmission between floors and rooms. This is particularly beneficial in areas where noise control is critical, such as office spaces, educational institutions, and residential buildings.

- Flexibility in Design and Construction. Lightweight concrete flooring systems offer greater design flexibility compared to traditional flooring options. The reduced weight allows for longer spans between support beams, enabling architects and engineers to create open and spacious interiors without compromising structural integrity. Additionally, lightweight concrete can be poured in various shapes, sizes, and thicknesses, making it suitable for different applications and architectural designs.

Advantages and Benefits of Lightweight Concrete Flooring

Reduced Structural Load

One of the most significant advantages of lightweight concrete flooring is its ability to reduce the overall structural load. Traditional concrete flooring, with its heavy aggregates, can place immense stress on the building’s foundation and structural support. In contrast, lightweight concrete flooring utilizes lightweight aggregates like expanded clay or shale, significantly reducing the weight without compromising strength. This reduction in load not only enhances the structural integrity but also allows for more design flexibility.

Enhanced Thermal Insulation

Another key benefit of lightweight concrete flooring is its superior thermal insulation properties. The air pockets within the lightweight aggregates act as natural insulators, reducing heat transfer through the floor. This helps maintain a comfortable indoor temperature throughout the year, reducing the need for excessive heating or cooling. As a result, buildings with lightweight concrete flooring can enjoy improved energy efficiency and lower utility costs.

Improved Soundproofing Capabilities

Noise pollution is a common concern in residential, commercial, and industrial buildings. Lightweight concrete flooring systems offer excellent soundproofing capabilities, thanks to the air pockets within the lightweight aggregates. These air pockets absorb and dampen sound vibrations, reducing noise transmission between floors and rooms. This is particularly advantageous in spaces where noise control is crucial, such as offices, schools, hospitals, and residential buildings.

Ease of Installation and Construction

Lightweight concrete flooring systems are relatively easy to install compared to traditional concrete flooring. The reduced weight of the materials makes handling and transportation more manageable, resulting in faster installation times and reduced labor costs. Additionally, lightweight concrete can be poured in various shapes, sizes, and thicknesses, allowing for greater design flexibility during the construction process.

Sustainability and Environmental Benefits

Lightweight concrete flooring is considered a sustainable option due to its reduced use of natural resources. The lightweight aggregates used in its composition are often recycled materials, such as expanded clay or shale, reducing the demand for virgin materials. Furthermore, the energy required to produce lightweight concrete is lower compared to traditional concrete, resulting in a smaller carbon footprint.

Types of Lightweight Concrete Flooring Systems

Foamed Concrete Flooring

Foamed concrete is a popular type of lightweight concrete flooring system. It is made by mixing a foaming agent with a cementitious binder and water. The foaming agent creates bubbles within the mixture, resulting in a lightweight and highly insulating material. Foamed concrete flooring is commonly used in areas where thermal insulation and weight reduction are critical, such as residential buildings, basements, and high-rise constructions.

Lightweight Aggregate Concrete Flooring

Another type of lightweight concrete flooring system is lightweight aggregate concrete. This system incorporates lightweight aggregates, such as expanded clay, shale, or slate, into the concrete mix. These aggregates provide the necessary strength while significantly reducing the overall weight of the flooring. Lightweight aggregate concrete flooring is versatile and can be used in various applications, including residential, commercial, and industrial buildings.

Autoclaved Aerated Concrete (AAC) Flooring

Autoclaved Aerated Concrete (AAC) is a lightweight concrete flooring system that consists of cement, lime, water, and a foaming agent. The mixture is poured into molds and then cured under high-pressure steam, resulting in a material with a cellular structure. AAC flooring offers excellent thermal insulation, fire resistance, and soundproofing capabilities. It is commonly used in both residential and commercial buildings, particularly in areas prone to seismic activity.

Cellular Lightweight Concrete Flooring

Cellular Lightweight Concrete (CLC) is a type of lightweight concrete flooring system that contains millions of evenly distributed air cells throughout the material. These air cells are created by mixing a foaming agent into the concrete mix. CLC flooring offers excellent thermal insulation, fire resistance, and a reduced overall weight. It is commonly used in construction projects where load reduction and thermal insulation are critical, such as residential buildings, commercial spaces, and infrastructure projects.

Precast Lightweight Concrete Flooring

Precast lightweight concrete flooring involves the manufacturing of concrete panels or slabs off-site, which are then transported and installed at the construction site. This method offers several advantages, including faster installation times, improved quality control, and reduced on-site labor requirements. Precast lightweight concrete flooring is commonly used in commercial and industrial buildings, where speed of construction and durability are essential.

Installation and Maintenance of Lightweight Concrete Flooring

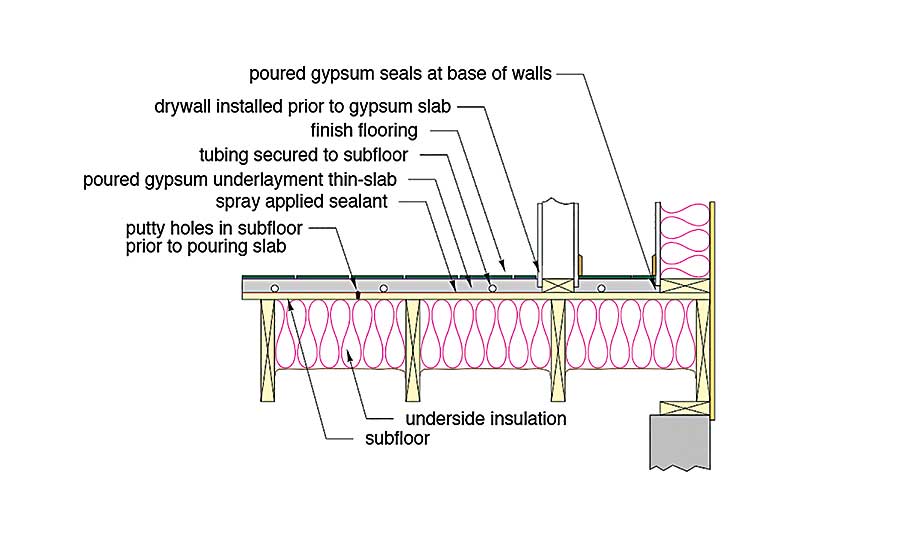

Installation Process

The installation process of lightweight concrete flooring is similar to that of traditional concrete flooring. It involves preparing the subfloor, pouring the lightweight concrete mix, and leveling and finishing the surface. However, there are some key considerations to keep in mind. Due to the reduced weight of the materials, handling and pouring should be done with care to avoid any damage or displacement. Additionally, it is crucial to follow the manufacturer’s guidelines and specifications for mixing ratios, curing times, and other installation requirements.

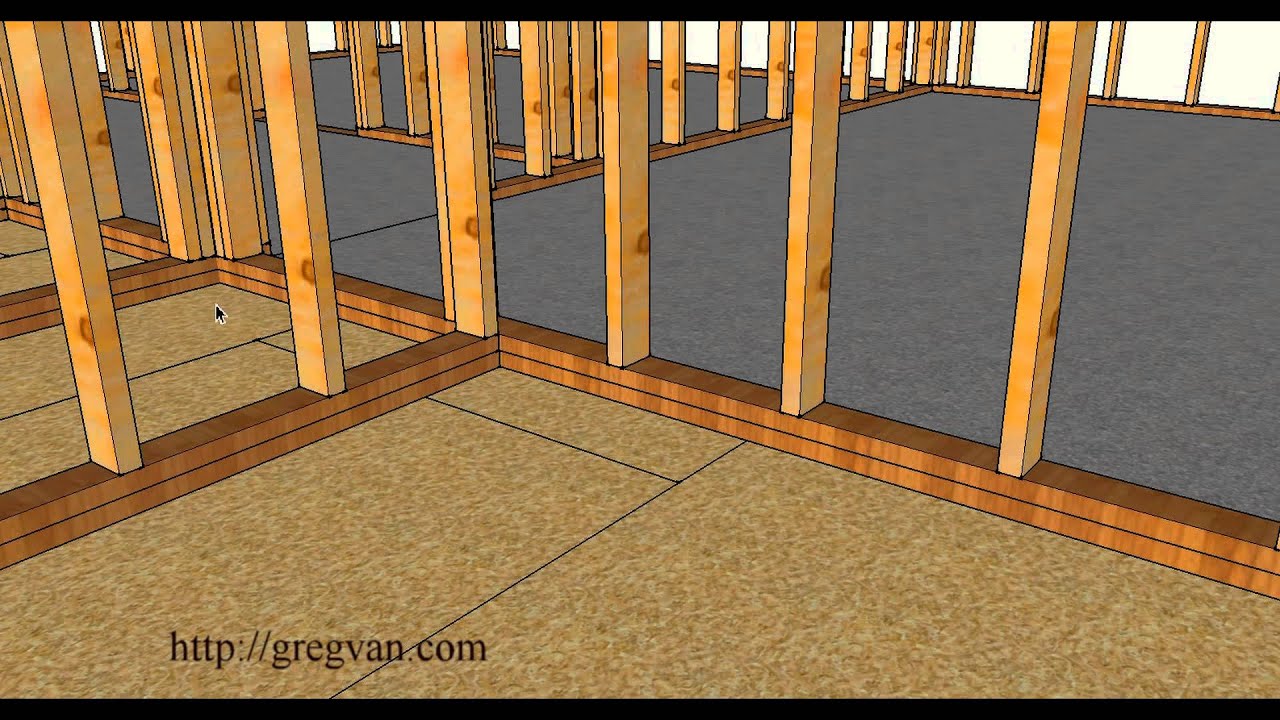

Subfloor Preparation

Before installing lightweight concrete flooring, the subfloor should be properly prepared. This includes cleaning the surface, removing any debris or loose materials, and ensuring a smooth and level base. If necessary, a moisture barrier or primer may be applied to prevent moisture penetration and improve adhesion.

Pouring and Leveling

Once the subfloor is prepared, the lightweight concrete mix can be poured onto the surface. It is essential to distribute the mix evenly and use proper techniques, such as screeding and troweling, to achieve a level and smooth finish. Care should be taken to avoid overworking the surface, as this can lead to surface defects or reduced strength.

Curing and Drying

After the lightweight concrete flooring is poured and leveled, it needs sufficient time to cure and dry. The curing process allows the concrete to gain strength and stability, while the drying process removes excess moisture. The duration of curing and drying may vary depending on factors such as ambient conditions, mix design, and thickness of the flooring. It is important to follow the manufacturer’s recommendations for curing and drying times to ensure the best results.

Maintenance and Care

Proper maintenance and care are essential for ensuring the longevity and performance of lightweight concrete flooring. Regular cleaning with a mild detergent and water is usually sufficient to remove dirt and stains. Avoid using harsh chemicals or abrasive cleaners that can damage the surface. Additionally, it is important to address any spills or accidents promptly to prevent staining or discoloration. Periodic inspections should also be conducted to identify and address any cracks or damages early on.

Successful Applications of Lightweight Concrete Flooring Systems

Residential Buildings

Lightweight concrete flooring systems have found successful applications in residential buildings. For example, in a multi-story apartment complex, lightweight concrete flooring was used to reduce the overall weight of the structure while maintaining its structural integrity. This allowed for the construction of additional floors without compromising safety or requiring costly reinforcements. Additionally, the thermal insulation properties of lightweight concrete flooring contributed to improved energy efficiency and reduced heating and cooling costs for the residents.

Commercial Spaces

Lightweight concrete flooring systems have also been widely implemented in commercial spaces. In a retail store, for instance, lightweight concrete flooring was utilized to create a durable and aesthetically pleasing surface capable of withstanding heavy foot traffic. The reduced weight of the flooring system facilitated faster installation times, minimizing disruptions to the store’s operations. Furthermore, the improved soundproofing capabilities of lightweight concrete flooring contributed to a quieter and more comfortable shopping experience for customers.

Educational Institutions

Lightweight concrete flooring systems have proven beneficial in educational institutions such as schools and universities. In a school building, lightweight concrete flooring was employed to reduce the overall weight on the foundation and support structure. This allowed for the construction of larger classrooms and common areas without compromising the safety of the students and staff. The enhanced thermal insulation properties of lightweight concrete flooring also contributed to a more comfortable learning environment, promoting better concentration and productivity.

Healthcare Facilities

Healthcare facilities have also benefited from the implementation of lightweight concrete flooring systems. In a hospital, for example, lightweight concrete flooring was used to create a hygienic and durable surface capable of withstanding heavy medical equipment and high foot traffic. The thermal insulation properties of the flooring system helped maintain a stable indoor temperature, contributing to patient comfort and energy efficiency. Additionally, the improved soundproofing capabilities of lightweight concrete flooring reduced noise transmission between rooms, creating a peaceful and healing environment for patients.

Industrial Buildings

The application of lightweight concrete flooring systems in industrial buildings has demonstrated significant advantages. In a manufacturing facility, lightweight concrete flooring was utilized to reduce the load on the structure while providing a sturdy and durable surface for heavy machinery and equipment. The reduced weight of the flooring system also allowed for the installation of larger equipment, optimizing productivity. Additionally, the thermal insulation properties of lightweight concrete flooring contributed to a more controlled and energy-efficient working environment.

Lightweight Concrete Floor Systems – Thickness, Uses – The Constructor

Lightweight Concrete Floor Systems – Thickness, Uses – The Constructor

Watch This Video Before Using Lightweight Concrete As Sound Barrier Between Floors

STRUCTURE magazine Is Lightweight Concrete All Wet?

Gothic Construction Techniques Inspire ETH Zurichu0027s Lightweight

Lightweight Concrete Topping Provides Seamless Walls and Flooring

Lightweight Concrete Floor with INEXu003eFLOOR UBIQ

Lightweight Concrete Floor Systems – Thickness, Uses – The Constructor

Related Posts:

- Polished Concrete Floors For Patios

- White Concrete Floor Tiles

- Acid Wash Concrete Floor Colors

- Concrete Floor Thickness For A Garage

- Concrete Floor For Bathroom

- Interior Concrete Floor Ideas

- Kitchen Stained Concrete Floors

- Concrete Floor Tile Thickness

- How To Stain Concrete Floors DIY

- DIY Concrete Floor Grinding