As someone who has experienced the challenges and triumphs of working with concrete floors, I understand how crucial it is to protect them from various hazards and extend their lifespan. In this article, we will dive deep into the world of Concrete Floor Membranes, exploring their types, benefits, installation, maintenance, common issues, environmental considerations, regulations, and future innovations. So, let’s lay a solid foundation for your knowledge and empower you to make informed decisions about this vital aspect of concrete flooring.

Understanding Concrete Floor Membrane

Concrete Floor Membrane, often referred to as a floor coating or sealant, is a protective layer applied over concrete surfaces. Its primary function is to shield the concrete from potential damages caused by moisture, chemicals, and physical stress, thus ensuring the durability of the floor over time. These membranes come in different types, including Sheet Membranes, Liquid Applied Membranes, and Self-Adhering Membranes, each with unique applications and advantages.

Advantages and Benefits of Concrete Floor Membrane

The benefits of using Concrete Floor Membranes are manifold, making them an indispensable investment for any concrete flooring project. One of the key advantages is moisture mitigation, as these membranes prevent vapor transmission and reduce moisture-related issues like mold and mildew growth. Additionally, they offer crack bridging and waterproofing properties, reinforcing the structural integrity and providing protection against water infiltration, which can lead to significant damage if left unchecked. Furthermore, the chemical resistance of these membranes helps shield the floor against harmful chemical spills and extends its longevity, minimizing maintenance costs in the long run.

Installation and Application

Proper installation of Concrete Floor Membranes is essential for ensuring their effectiveness and longevity. Before application, thorough surface preparation is necessary, involving cleaning, leveling, and addressing any cracks or imperfections in the concrete. The application techniques differ depending on the type of membrane being used, with Sheet Membranes requiring precise measurement and careful installation, Liquid Applied Membranes being applied using rollers or spray equipment, and Self-Adhering Membranes being simply unrolled onto the prepared surface. Curing and drying times must be observed diligently, and environmental conditions during installation should be carefully considered to achieve optimal results.

Maintenance and Inspection

Regular maintenance and inspection play a pivotal role in preserving the effectiveness of Concrete Floor Membranes. Implementing a routine inspection protocol helps identify any potential issues at an early stage, allowing for timely repairs. Proper cleaning and maintenance practices not only maintain the aesthetic appeal of the floor but also prevent debris buildup, which can compromise the membrane’s performance. If damages do occur, prompt repairs or reapplication of the membrane become necessary to avoid further deterioration and protect the underlying concrete.

Common Issues and Troubleshooting

Despite the robustness of Concrete Floor Membranes, they may encounter certain issues over time. These include blistering and bubbling, often caused by improper installation or trapped moisture during application. Adhesion failure can also occur if the surface preparation is inadequate, leading to a lack of proper bonding between the membrane and the concrete. Cracking and delamination may arise due to temperature fluctuations or excessive stress, while moisture trapping can result from improper ventilation. Furthermore, exposure to harsh chemicals can weaken the membrane’s integrity and cause chemical damage.

Case Studies

Let’s delve into real-life scenarios where Concrete Floor Membranes have played a crucial role in safeguarding different types of spaces. We will explore case studies from industrial facilities, commercial buildings, and even residential applications, showcasing the effectiveness of various membrane types in diverse environments.

Environmental and Sustainability Considerations

With environmental consciousness on the rise, the construction industry is embracing eco-friendly practices. We’ll explore the different options available for eco-conscious builders, including sustainable and biodegradable membrane solutions. Additionally, we’ll discuss how these choices contribute to LEED certification and align with green building standards.

Regulations and Standards

Compliance with industry regulations and standards is of paramount importance when it comes to Concrete Floor Membranes. We’ll delve into the ASTM International Standards governing membrane products, building codes, and essential health and safety guidelines, ensuring that your projects adhere to the highest standards.

Future Trends and Innovations

As technology continues to advance, so does the world of Concrete Floor Membranes. In this section, we will explore the latest advancements in membrane technology, such as integrating smart and sensor-enabled membranes that offer real-time data and increased efficiency. Moreover, we’ll look into the development of sustainable and biodegradable membrane options, anticipating a greener future for the construction industry.

Split Slab · Sika Emseal

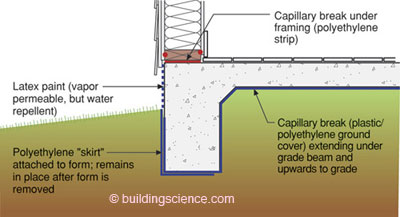

Concrete Floor Problems Building Science Corporation

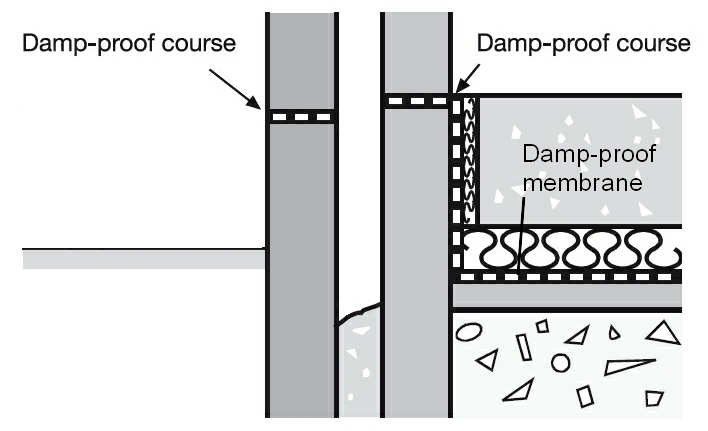

Damp proof membrane DPM – Designing Buildings

Slip Membrane – CoGripedia – CoGri Group Ltd

How to Install Tile Over Concrete – GreenBuildingAdvisor

FLORPRUFE® 120 Resource GCP Applied Technologies

What is a Vapour Barrier Under A Concrete Slab – The Structural

SUPERSEAL High Flow Dimpled Membrane for Concrete Slabs

Underslab Retrofits: Sealing Slabs WATERPROOF! Magazine

How to Waterproof a Concrete Slab

PMPC – Vaporproofing/Waterproofing Membrane – W. R. Meadows

Related Posts:

- How To Stain Concrete Floors Outdoors

- DIY Stained Concrete Floors In Homes

- Concrete Floors Look Like Marble

- Concrete Floor Slab Mix Ratio

- Dark Brown Concrete Floor Paint

- Pretty Concrete Floors

- Stained Concrete Floors For Homes

- Decorative Concrete Floor Ideas

- Pouring A Concrete Floor In A Garage

- How To Get Smooth Concrete Floor