Have you ever walked into a room and felt the warmth and beauty of real wood flooring underfoot? If you’re intrigued by the idea of wood floors but also curious about sustainability and practicality, then engineered wood flooring might be your answer. Today we are going to talk about engineered wood flooring, where artistry and engineering collide to create a flooring option that’s as stylish as it is environmentally conscious.

Understanding Engineered Wood Flooring

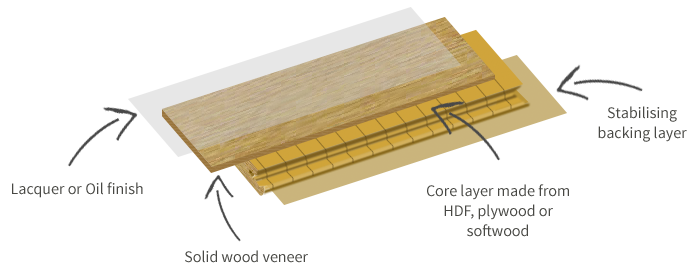

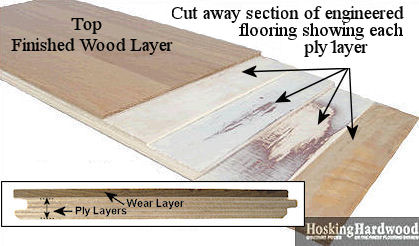

Let’s start with the basics. Engineered wood flooring is like the ingenious lovechild of hardwood and modern technology. It’s made up of layers—real wood on top and sturdy plywood or HDF underneath. What makes it special? Well, it offers the beauty of hardwood with added stability, thanks to its layered composition. Plus, it’s often more budget-friendly and sustainable than traditional hardwood.

Layer by Layer: The Crafting Process

So, how is this marvel crafted? It’s a meticulous process that involves layering different materials to create a composite material that’s both strong and good-looking. Imagine a sandwich: the top layer is the “wear layer,” which is the actual hardwood that you see and feel. Then there are the core layers, usually made from plywood or HDF, providing stability and strength. These layers are carefully bonded together to create a robust foundation.

The Wear Layer: Real Wood Beauty

Let’s talk about the star of the show—the wear layer. This is where the magic happens. It’s real hardwood, the stuff that’s sourced from trees, giving you that authentic wood experience. The wear layer is what you walk on, what you admire, and what sets the tone for your flooring’s aesthetics. It’s like having a slice of nature right in your home.

The Core Layers: Stability and Strength

But what about those core layers? They might not be as glamorous, but they’re the unsung heroes of engineered wood flooring. These layers provide stability, making sure your floor doesn’t warp or bend when temperature and humidity play their games. It’s a bit like having a solid backbone—the kind that ensures your floor stands strong for years to come.

The Adhesive Process: Bonding Layers Together

Now, let’s talk about glue—yes, glue! Adhesive plays a crucial role in this craftsmanship. It’s the glue that brings the layers together, creating a bond that’s strong and enduring. The adhesive needs to be of high quality, ensuring that the layers stay put even in the face of daily wear and tear.

The Pressing Phase: Heat and Pressure

Once the layers are bonded, it’s time for a little transformation magic. The layers are subjected to heat and pressure, a bit like a cozy hug from the manufacturing process. This pressing phase is what fuses everything together, creating a solid, sturdy material that’s ready to become your flooring.

Precision Milling and Finishing

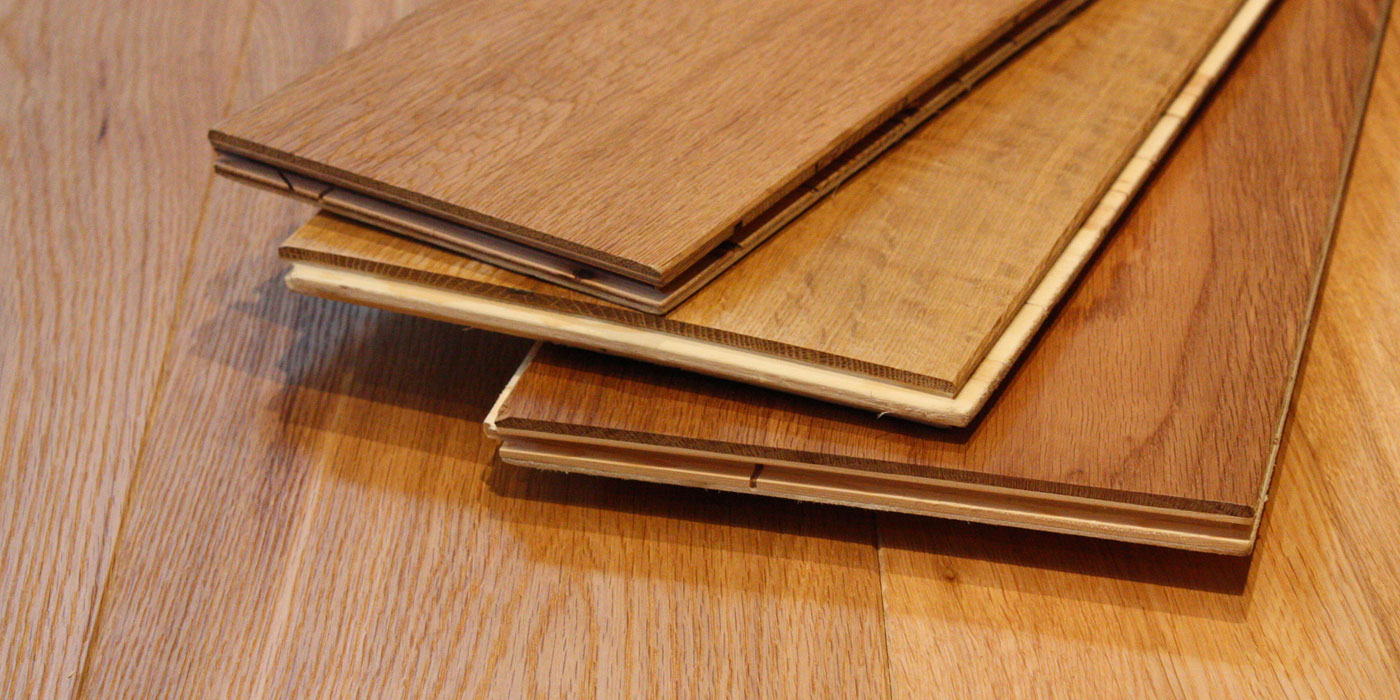

Once the composite material is ready, it’s time for precision. Each plank is carefully milled to ensure consistent dimensions. And those familiar tongue-and-groove edges? They’re not just for show; they make installation a breeze, allowing the planks to fit snugly together like a well-orchestrated puzzle.

Surface Treatments and Styles

Now comes the fun part—adding character and style. Different surface treatments and finishes are applied to give the flooring its final appearance. Staining can give your flooring a distinct hue, while lacquering adds a protective sheen. And if you’re a fan of texture, you’ll find options that mimic the natural feel of wood.

Quality Assurance and Environmental Considerations

Quality control is the name of the game. Manufacturers ensure that every step is precise, from layer bonding to finishing touches. And here’s a bonus: engineered wood flooring is often more sustainable than traditional hardwood. It uses fewer precious trees, opting for a veneer of real wood over a stable core. So, you get both style and environmental consciousness.

Installation and Versatility

When it’s time to install your engineered wood flooring, you’ll find it’s remarkably versatile. It can be nailed, glued, or floated, making it suitable for various spaces and preferences. And guess what? It’s even a great choice for places like basements, where moisture levels can be a concern for solid hardwood.

Caring for Engineered Wood Flooring

Maintenance? It’s not as daunting as it sounds. Regular sweeping and gentle cleaning with the right products is all it takes to keep your engineered wood floors looking their best. Just remember, treat them with care, and they’ll reward you with lasting beauty.

So, there you have it—the artistry and engineering behind engineered wood flooring. It’s like a symphony of layers, each playing a role in creating a floor that’s as stunning as it is functional. As you step onto your engineered wood floors, know that you’re walking on a masterpiece—a masterpiece that marries the beauty of nature with the brilliance of human ingenuity.

Engineered Wood Flooring: Homeowner Pros u0026 Cons

All About Engineered Wood Flooring

Engineered Flooring Guide Engineered Floors FlooringSupplies.co.uk

Engineered Flooring Vs Laminate Flooring: Everything You Need To

All About Floating Wood Floors

Engineered Wood Flooring Signature Home Inspection

The Definitive Guide to Engineered Wood Floors

Whatu0027s Better: Solid vs Engineered Hardwood Flooring – LV Hardwood

Related Posts:

- Wood Floor Kitchen Cabinet Combination Designs

- Solid Wood Floor Repair Kit

- Dark Wood Floor Finishes

- Light Oak Solid Wood Flooring

- Grey Wood Floor In Bathroom

- Pledge Wood Floor Cleaner Spray

- Wide Plank Wood Flooring Cost

- Light Wood Flooring Ideas

- Click Lock Wood Flooring Pros And Cons

- Non Slip Wood Floor Cleaner