Concrete floor construction with insulation is a crucial aspect of modern building design, offering a range of benefits that enhance both structural integrity and energy efficiency. Insulating concrete floors involves the incorporation of insulating materials within the concrete slab or below it, serving as a thermal barrier that helps regulate indoor temperatures and minimize heat loss. One common method is the use of rigid foam insulation boards, which are placed beneath the concrete slab during construction. These boards possess excellent insulating properties, effectively reducing heat transfer between the interior and exterior of a building. This not only enhances the comfort of indoor spaces but also leads to significant energy savings by reducing the need for continuous heating or cooling.

Images about Concrete Floor Construction With Insulation

Concrete Floor Construction With Insulation

Furthermore, concrete floor insulation is especially valuable in regions with extreme temperatures. In colder climates, it prevents the floor from becoming uncomfortably cold, ensuring a more pleasant living or working environment. Conversely, in warmer regions, insulation can help maintain cooler indoor temperatures by preventing the intrusion of external heat, thereby reducing the reliance on air conditioning systems. This not only translates into cost savings but also contributes to environmental sustainability by lowering energy consumption and reducing greenhouse gas emissions.

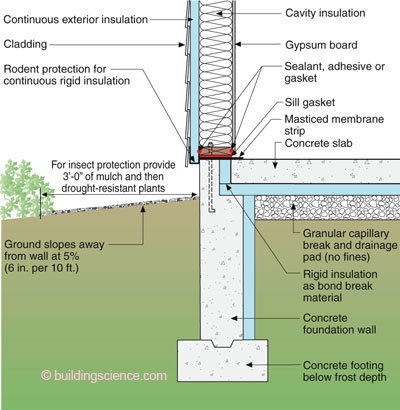

Slab Happy & Concrete Engineering Building Science

In addition to its thermal benefits, insulating concrete floors also offer sound insulation advantages. These floors reduce the transmission of noise between floors or rooms, enhancing acoustic comfort in multi-story buildings or areas with high foot traffic. Whether in residential, commercial, or industrial settings, insulating concrete floors contribute to a quieter and more peaceful living and working environment. In conclusion, concrete floor construction with insulation is a versatile solution that improves thermal efficiency, lowers energy consumption, and enhances acoustic comfort. Its adoption is a vital step in constructing sustainable and comfortable buildings that meet the demands of modern living while also contributing to reduced energy consumption and environmental preservation.

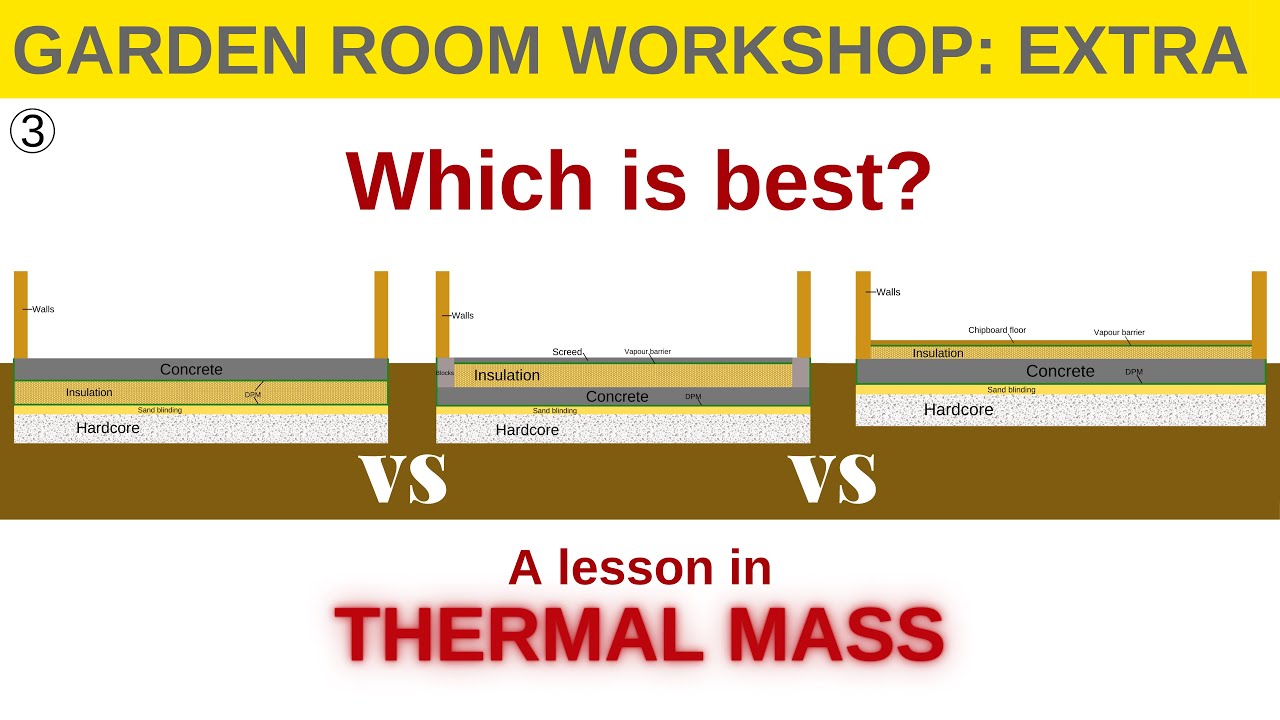

Garden Room Workshop Extra Insulating A Concrete Slab

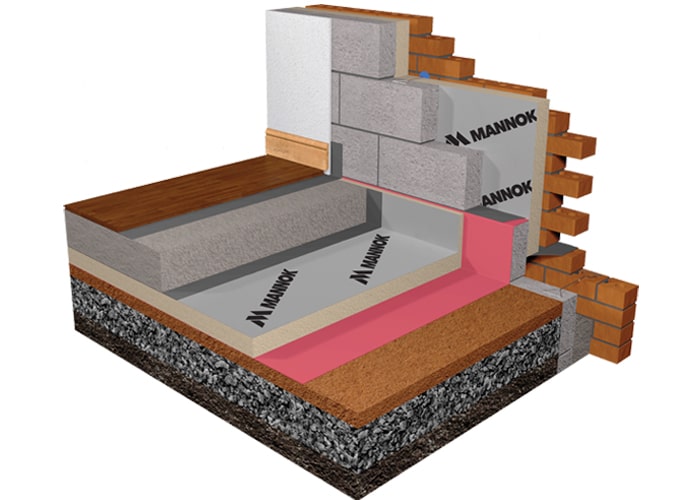

Floor Insulation – Mannok

How to Insulate a Raised Floor – GreenBuildingAdvisor

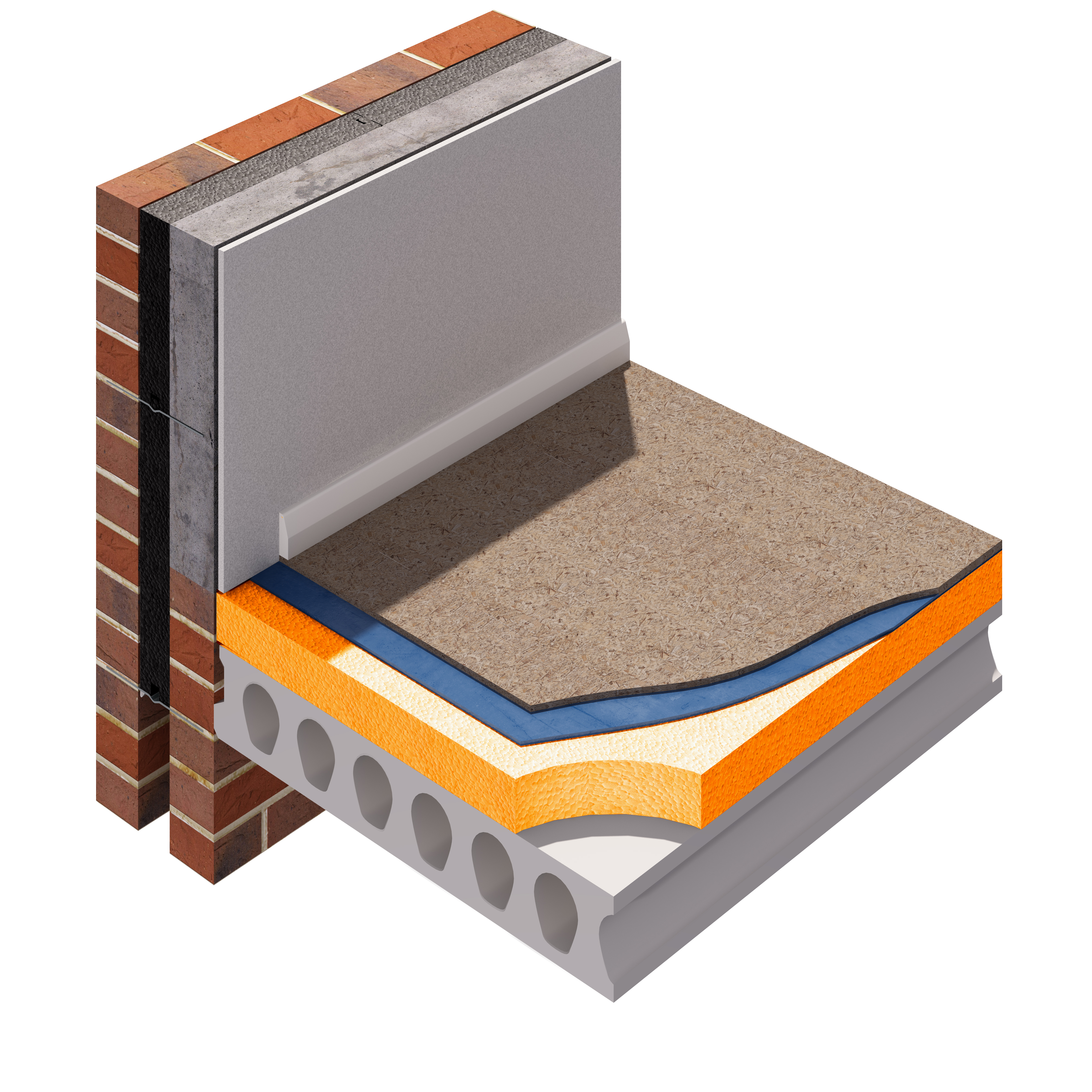

Flooring Concrete floors, Flooring, Concrete furniture

Installing Rigid Foam Above a Concrete Slab – GreenBuildingAdvisor

Insulation for ground floors – Designing Buildings

Insulating a floor – Insulation Superstore Help u0026 Advice

Related Posts:

- How To Stain Concrete Floors Outdoors

- DIY Stained Concrete Floors In Homes

- Concrete Floors Look Like Marble

- Concrete Floor Slab Mix Ratio

- Dark Brown Concrete Floor Paint

- Pretty Concrete Floors

- Stained Concrete Floors For Homes

- Decorative Concrete Floor Ideas

- Pouring A Concrete Floor In A Garage

- How To Get Smooth Concrete Floor

Introduction

Concrete floor construction with insulation is a popular choice for residential and commercial buildings. It is an effective way to provide thermal and acoustic insulation and also helps to reduce energy costs. The concrete floor construction with insulation is a relatively simple process that involves laying down a layer of insulation material before pouring the concrete onto it. This provides a high level of insulation that is both cost-effective and long-lasting. This article looks at the different types of insulation materials used, the advantages and disadvantages of using concrete floor construction with insulation, and some frequently asked questions about the process.

Types of Insulation Materials Used for Concrete Floor Construction

When constructing a concrete floor, there are several types of insulation materials that can be used. These include rigid foam board insulation, loose fill fiberglass and cellulose, and spray foam insulation. Each type of material has its own advantages and disadvantages, so it’s important to choose the one that best suits your needs.

Rigid Foam Board Insulation

Rigid foam board insulation is one of the most popular options for concrete floor construction with insulation. It is made from polystyrene or polyurethane and comes in a variety of thicknesses. This type of insulation is highly effective at keeping heat in or out, depending on what you are trying to achieve. It is also relatively easy to install and doesn’t require any special tools or equipment. The downside is that it can be quite expensive compared to other options.

Loose Fill Fiberglass and Cellulose

Loose fill fiberglass and cellulose are another popular option for concrete floor construction with insulation. They are both made from recycled materials such as glass fibers or paper products. The advantage of these materials is that they are lightweight and easy to install. In addition, they are both highly effective at keeping heat in or out of a space, depending on what you are trying to achieve. However, they can be more prone to settling over time than other types of insulation materials.

Spray Foam Insulation

Spray foam insulation is also becoming increasingly popular for concrete floor construction with insulation. This type of material is sprayed onto the surface of the concrete before it sets, creating an airtight seal that helps keep heat in or out, depending on what you are trying to achieve. It also provides an effective barrier against moisture and air leakage. The downside is that it can be more expensive than other types of insulation materials.

Advantages & Disadvantages of Concrete Floor Construction With Insulation

Concrete floor construction with insulation offers several advantages over other types of construction methods. Some of these advantages include:

– Improved energy efficiency: Concrete floors constructed with insulation help to reduce energy costs by keeping heat in or out, depending on what you are trying to achieve.

– Enhanced sound control: Insulating a concrete floor helps to reduce noise levels in a space by providing better soundproofing.

– Increased durability: Concrete floors constructed with insulation tend to be more durable than those without because the added layer of insulation provides additional protection from damage caused by extreme temperatures or moisture buildup.

– Cost savings: Installing an insulating layer under a concrete floor can save money in the long run by reducing energy costs and providing extra protection from damage caused by extreme temperatures or moisture buildup.

However, there are some drawbacks associated with using concrete floor construction with insulation as well. These include:

– Installation costs: Installing an insulating layer under a concrete floor can be expensive compared to other types of construction methods due to the additional labor required for installation.

– Higher maintenance costs: An insulating layer under a concrete floor may require more frequent maintenance than other types of floors due to the risk of moisture buildup or damage caused by extreme temperatures.

– Increased weight: An insulating layer under a concrete floor will add additional weight which can increase stress on the structure if not taken into account during design and installation.

FAQs About Concrete Floor Construction With Insulation

Q1: What type of material should I use for my concrete floor insulation?

A1: The type of material you should use for your concrete