Nonetheless, the trouble with DIY floor concreting is you may not be able to mix an actual proportion for the cement as well as water mixture and often will result in a terrible result. Concrete flooring polishing can turn the surface area into an elegant flooring. Concrete flooring appears great of residences as it blends well with home furnishings.

Images about Concrete Floor Sealing Systems

Concrete Floor Sealing Systems

Dealing with polished concrete floors is a thing that the majority of people might not be perfectly clued about. Do you've polished concrete floors, or perhaps maybe terrazzo floors? This will make knowing what paint type to go with a lot easier. Dust, dander and dust mites can all be stopped by utilizing this kind of flooring.

Garage Floor Sealers Guide From Densifiers to Epoxy Coatings

With concrete flooring, after the floors are laid, they're polished to a substantial gloss and left on display. Those the majority of enthusiastic about developing environmentally sustainable homes have been among the first to adopt polished concrete floors, and also with great reason. Warehouses as well as basements are the ideal purposes for polished concrete floor.

4 Types of Concrete Floor Coatings (And What You Should Know

Concrete Coatings Garage Floor Coating Penntek Coatings

Grind and Sealed Concrete Floor at Orfila Winery – Westcoat

Concrete Floor Coating Maintenance and Sustainability Basement

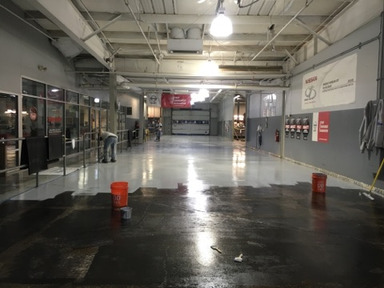

sealing concrete floor of shop

Concrete Sealers for Access Floor Systems – Seal Bond – Made in

Floor Coating Chip Sealer – Less Expensive Top Coats Slide-Lok

Epoxy Systems For Concrete Floors – Concrete Decor

concrete floor coating systems Archives – CoverTec Products

HyperREZ UV Low Temp 40°F High Build Epoxy Concrete Floor Coating 100% Solids

Epoxy Floor Coatings Garage Floor Coatings – GarageFloorCoating.com

Garage Floor Coating u2013 Everything You Need to Know (2022

Related Posts:

- How To Stain Concrete Floors Outdoors

- DIY Stained Concrete Floors In Homes

- Concrete Floors Look Like Marble

- Concrete Floor Slab Mix Ratio

- Dark Brown Concrete Floor Paint

- Pretty Concrete Floors

- Stained Concrete Floors For Homes

- Decorative Concrete Floor Ideas

- Pouring A Concrete Floor In A Garage

- How To Get Smooth Concrete Floor

Introduction

Concrete floor sealing systems are essential components of any facility or building that needs a durable, long-lasting surface. By sealing concrete floors, you can protect them from staining, water damage, and wear and tear. The right sealant will also help keep the surface looking good for years to come. In this article, we’ll look at the different types of sealants available, as well as their pros and cons. We’ll also provide some frequently asked questions about concrete floor sealing systems, so you can make an informed decision about which one is right for your needs.

Types of Sealants

There are several different types of sealants that can be used to protect concrete floors. The most common types are acrylics, polyurethanes, epoxies, and silicones. Each has its own advantages and disadvantages, so it’s important to choose the right one for your needs.

Acrylics

Acrylics are the most common type of concrete sealant. They are easy to apply and provide good protection against water and staining. They are also relatively inexpensive and last for a long time. However, acrylics don’t provide very good protection against wear and tear, so they may not be the best choice for areas where there is a lot of foot traffic or heavy equipment use.

Polyurethanes

Polyurethanes are more expensive than acrylics but they provide better protection against wear and tear. They are also more resistant to staining and water damage. However, they can be difficult to apply and may require professional installation.

Epoxies

Epoxies are the most durable type of sealant and provide excellent protection against wear and tear. They are also highly resistant to staining and water damage. However, they are more expensive than other types of sealants and can be difficult to install.

Silicones

Silicones are the least durable type of sealant but they provide good protection against staining and water damage. They are also easy to apply and relatively inexpensive. However, they may not last as long as other types of sealants.

Pros & Cons

When choosing a sealant for your concrete floor, it’s important to consider the pros and cons of each type. Acrylics are easy to apply and relatively inexpensive but don’t provide much protection against wear and tear. Polyurethanes provide good protection against wear but can be difficult to install and expensive. Epoxies are highly durable but also expensive and difficult to install. Silicones are easy to apply but don’t last as long as other types of sealants.

FAQs

Q: What is the best type of sealant for my concrete floor?

A: The best type of sealant depends on your specific needs. If you need a sealant that provides good protection against wear and tear, then epoxies or polyurethanes may be the best option. If you need a sealant that is easy to apply and relatively inexpensive, then acrylics or silicones may be the better choice.

Q: How often should I reseal my concrete floor?

A: It depends on the type of sealant you use. Generally speaking, acrylics should be resealed every two to three years while polyurethanes or epoxies should be resealed every five to seven years. Silicones should be resealed every one to two years.

Q: How much does it cost to have my concrete floor sealed?

A: The cost of having your floor sealed depends on the size of the area that needs to be sealed as well as the type of sealant used. Generally speaking, acrylics or silicones will cost less than polyurethanes or epoxies. It’s best to get an estimate from a professional before having your floor sealed so you know what to expect in terms of cost.

Conclusion

Concrete floor sealing systems can provide long-lasting protection against staining, water damage, and wear and tear. There are several types of sealants available, each with its own advantages and disadvantages. When selecting a sealant for your concrete